Zonal Isolation

Composite Frac Plugs Optimize Cost, Capabilities In Plug-And-Perf Completions

By Matthew Crump

HOUSTON–For shale play operators using multistage hydraulic fracturing in their horizontal completions, the slowdown in the frantic pace of drilling and completions activity is changing the economics of zonal isolation.

Many operators are shifting their completion designs to the plug-and-perf multizone fracturing method, using composite plugs pumped down hole with water and set in place to isolate zones and ensure that stimulation fluids are directed into a specific zone. By some industry estimates, more than 80 percent of hydraulically fractured wells employ plug-and-perf completions both because of the favorable deployment economics and the fact that the technique enables greater flexibility in designing and pumping stimulation jobs.

Operators can deploy cased-hole logging techniques to pinpoint the most productive zones along the lateral and then change the plug-and-perf program “on the fly” to deploy plugs at the intervals targeted for perforating and completion. The number of zones and the distance between subsequent stages can be changed quickly in a well.

This degree of flexibility is not possible with sliding sleeve completion tools that are opened or closed mechanically using ball drops or coiled tubing to allow stimulation fluids to selectively fracture zones in the formation. Sliding sleeves are an attractive multistage stimulation option thanks to the efficiency they bring in terms of reduced rig time, faster operations and limited water usage, especially when windows for scheduling frac jobs are tight. However, because the sleeves are installed with the casing, sleeves cannot be moved once a casing string is installed.

While the plug-and-perf technique affords cost savings to a well completion design, operators continue to search for ways to further optimize well completions in ways that maximize production while minimizing costs. One focus of this optimization initiative has been in the design of new composite frac plugs.

Composite plugs generally contain relatively high amounts of metal. The length of traditional plugs increases the amount of material that must be milled out across multiple zones. In some cases, a well may contain 55 or more frac plugs set in a lateral that is one mile or more in length.

Traditional composite plugs also tend to have rough edges and protrusions that can catch on ledges and casing joints, causing the plug to preset in the lateral or become stuck. Composite plugs with primarily metallic slips leave large amounts of debris in the wellbore, which makes milling operations more complex, lengthy and costly.

Optimizing Plug Performance

While it is critical to reduce metal content for improved plug run-in and mill-out, a balance must be struck between optimizing run-in and mill-out performance and achieving the required anchoring force to set the plug and ensure isolation in the targeted zones.

The newest generation of composite frac plug technology uses a blend of 97 percent composite material. The low metal content and advanced composite materials provide a plug that delivers higher run-in speeds, reliable anchoring, improved seal integrity, and reduced mill-out time with smaller-sized cuttings.

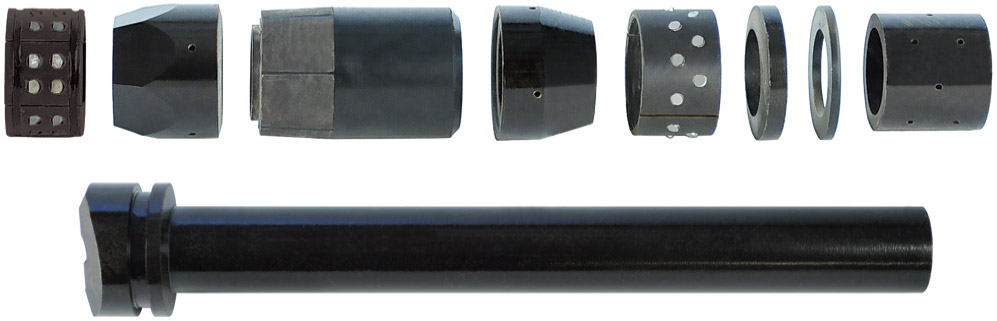

The key to the success of a composite frac plug solution is in designing and optimizing the individual components–including the lower slip assembly and cone, molded element system, and upper slip assembly (Figure 1)–to perform their designated functions in hole, while fitting together into a lightweight and compact design capable of holding a high-pressure, competent seal.

The first component, an upper slip, is machined from a single piece of filament-wound composite and paired with powdered metal buttons. The buttons provide a high-strength anchoring force into the casing string. Both the buttons and composite structure mill easily, allowing each plug to drill out quickly into small pieces for an efficient return.

The newest composite plug design also incorporates a molded element system with a smooth surface devoid of rough edges or protrusions, which lowers the risk of the plug presetting or getting stuck while running into the hole. The support structure is molded directly into the element body, which further reduces the risk of element flaring during deployment. As a result, the plug can be run in hole at speeds of up to 500 feet a minute, which is roughly twice the speed of conventional plugs.

Once the plug is set, the element provides a high-integrity seal rated for a maximum pressure of 10,000 psi and temperatures to 300 degrees Fahrenheit, making it suited for deploying in diverse wellbore environments. The element’s backup structure prevents extrusion while holding pressure. And because it is molded into the element, the backup structure results in smaller element pieces during mill-out operations.

The lower slip provides the main anchoring force to hold the plug in place during hydraulic fracturing of the zone. Using a combination of high-strength composite and small hardened inserts, the lower slip provides superior anchoring force with a minimal amount of metal. Once the milling operation begins, the slip’s composite material and small buttons break up quickly into a small size distribution for more efficient well cleaning.

A beveled mule shoe is affixed to the end of the plug next to the lower slip. During mill out, the beveled shoe acts as a clutch that locks onto the top of the plug below it to prevent the plug body from spinning as it is milled, increasing milling efficiency and decreasing mill-out time.

Field Trials

Composite plugs designed for 5 1⁄2-inch casing were run in a series of field trials conducted over six months in the winter and spring of 2014. The field trials uncovered design issues with the plug that caused issues during run-in. In each instance, design engineers pulled the plugs and conducted a thorough investigation of the root cause of the problems. Working with the internal design and composite engineering groups, the engineers made the necessary changes to the design to prevent similar problems on subsequent deployments.

In the first field trial, 31 plugs were run in a well in Northeast Texas. One plug hung up in the vertical section of the well during deployment and was pulled on wireline. An examination at the surface showed that the upper slip band had broken, allowing the lower slips to contact the casing. The operator was not concerned with this issue and continued deploying the plugs without additional issues.

In another Northeast Texas field trial, two plugs stuck in the well during deployment, leading to an investigation of problems with the plug design itself. Collaboration between field and design engineers resulted in a redesign that added a composite pin to each of the lower slips, which required an additional 1,000 pounds of force to break the lower slip ring and prevent premature setting. Adding these pins did not adversely affect the performance of the plug or the slip.

Three weeks later, 52 plugs were run on a two-well pad operation in the Permian Basin. While each plug incorporated the design changes to fix issues encountered in the previous field runs, one plug still became stuck during deployment. Examining the plug showed that the lower slip had broken, and one slip segment was missing. A full analysis of the plug dimensions suggested the standoff from the minimum outside diameter of the plug and maximum outside diameter of the slip buttons was too small. The slips were redesigned to increase this clearance while at the same time reinforcing them for additional strength.

A final field trial in the Permian Basin used 23 plugs in one well. While the plugs were deployed down hole without getting hung up, two of the plugs were initially pumped past their desired setting depth. When the operator attempted to pull the plugs up to location with wireline, they would not move. This led the design team to believe that the upper slip was breaking during run in, which would not be an issue until the plug was pulled up hole.

The slip was subsequently reinforced to increase the break force on the upper slip, and the problem has not been observed since. After this final revision, the composite plug technology has performed with extremely high reliability in more than 19,000 runs in all U.S. basins.

Functionality And Efficiency

The field trials helped prove the plug’s functionality and efficiency in a variety of well architectures, while allowing design problems to be identified quickly and addressed. The culmination of the design, laboratory qualification and field trial work was a more compact and lighter plug with a smoother outside diameter body and minimal metal content to provide the necessary sealing strength while circumventing many of the deployment and milling challenges common to legacy plugs.

For example, the high-integrity seal provided by a largely composite-based plug allows each plug to be 2 1⁄2 to 9 inches shorter than other composite frac plugs. In a multistage completion with 35 plugs, using a shorter composite plug can significantly reduce the amount of material to mill through, on the order of 18 feet in some cases. Reduced milling footage, of course, translates directly to rig time savings.

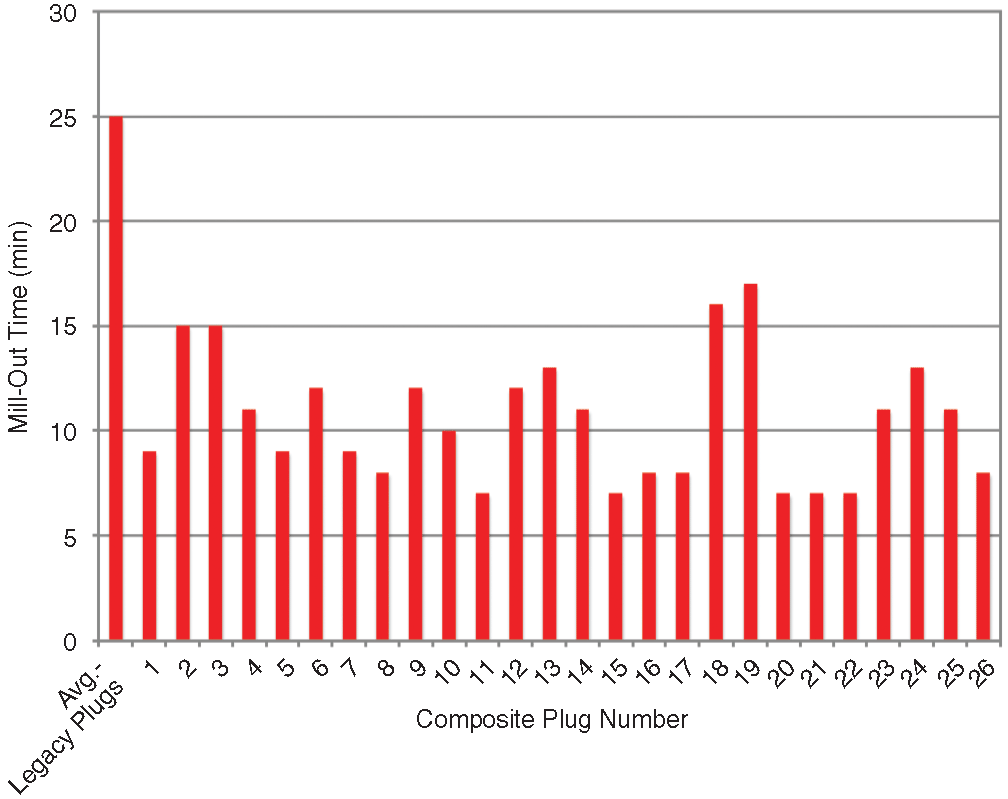

The composite material also allows for rapid drill-out using conventional drilling equipment, including coiled tubing drilling motors. The plug’s average mill-out time of 10.5 minutes per plug represents a 50 percent reduction in the milling times typical of traditional plugs.

Figure 2 shows mill-out times in an Eagle Ford well. Each plug was milled much faster than the average mill-out time for plugs used in previous wells (far left), with many plugs milling out in half the time. In addition, the composite material consistently mills into small, lightweight cuttings to minimize the risk of plugging surface equipment.

Further refinements include adding an optional pump-down ring on the mule shoe. This ring has a slightly larger outside diameter than the plug, which creates a larger overall outside diameter for the plug assembly to capture the full hydraulic energy of the fluids conveying the plug down hole. A pump-down ring can pump the plug into position more quickly and with less water.

This was demonstrated in a field trial in which two plugs were run into a well. One plug was equipped with a pump-down ring and the other was pumped without a ring. For the plug run without the pump-down ring, 300 barrels of fluid were required to get the plug to the setting depth 10,873 feet in the well and with a maximum line speed of 219 feet/minute.

The plug with the pump-down ring installed was deployed with a maximum line speed of 380 feet/minute and required only 147 barrels of fluid to get the plug to a target depth of 10,596 feet. Extrapolating these results to a well with 30 frac stages, the reduced fluid requirement would result in a 50 percent reduction in the amount of water required to pump a plug to its location.

Since the field trials and subsequent design changes, the new composite frac plug has set successfully and held pressure more than 99.9 percent of the time in thousands of well runs. The technology is suitable for a wide range of applications–including vertical, deviated, horizontal and multilateral wellbores–and also enables underbalanced drill-out of multiple plugs to protect sensitive formations.

Ultimately, composite plug technology’s deployment flexibility, reliable sealing during stimulation, and easy mill-out combine to make it an economically attractive and efficient component of the lower-cost completion in any oil price environment.

MATTHEW CRUMP is composites product line manager at Weatherford. He joined the company in 2011, and previously served as product line manager of open-hole packers and as product line champion for completions. Before joining Weatherford, Crump served in business development and project management roles at Baker Hughes, and as a project manager at Redding Linden Burr Consulting Engineers. He holds a B.S. in mechanical engineering from Texas A&M University and an M.B.A. in finance from the University of Houston.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.