Emergence Of Residual Zones, Price And Supply Factors Usher In New Day In CO2 EOR

By L. Stephen Melzer

MIDLAND, TX.–An exciting new development is emerging from ongoing carbon dioxide research and demonstration projects in the Permian Basin, underscoring win/win opportunities to increase oil recovery rates from mature fields while providing the means to efficiently and safely store CO2 generated from industrial and other sources.

Heretofore unrecognized targets for significant oil production lie beneath the oil/water contacts in large fields in West Texas and southeastern New Mexico. Nine projects are under way to test the commercial feasibility of producing oil from intervals that would produce only water in primary or secondary phases of production. Enhanced oil recovery techniques, specifically CO2 EOR, are demonstrating the feasibility of producing the immobile oil in the so-called residual oil zones beneath these fields.

One of the intriguing aspects of this opportunity is that it can not only produce potentially huge volumes of oil, but also can permanently store enormous volumes of CO2. This can provide the environmental benefit of reducing carbon emissions from traditional fossil fuel power generation and other industrial processes.

The current view is that carbon capture and storage is a most difficult proposition at any meaningful scale because of the extraordinary volumes of CO2 emissions. Most argue that it is still years–and possibly decades–away. Capture costs appear to be unacceptably high, the “energy penalty” for capture on conventional coal-fired power plants is too great, the distribution network to move the carbon dioxide to “repositories” is not in place, and the determination of safe and acceptable permanent sequestration is not ready for accepting CO2 for a multitude of reasons.

Overlaying these barriers is the belief held in some circles that since coal and oil are the main culprits in climate change, they should not “benefit” from a clean energy solution. Yet, it is becoming increasingly obvious that the optimum set of solutions come from these same industries using capture technologies, transportation infrastructure and enhanced oil recovery operations.

On the supply side, most would agree that there is a worldwide abundance of dilute carbon dioxide in the form of industrial emissions. With some notable exceptions, there has been essentially no movement to utilize it to meet fast growing EOR demand. The oil industry has had to rely on natural deposits trapped in underground source fields to supply its increasing needs. And on the demand side, the conventional thinking has been that EOR is simply not a big enough target to make a difference to drive CO2 capture to any significant degree. But all that is changing very rapidly with increasing oil prices, improvements in capture technologies, and especially, the new-found recognition that huge commercial targets exist below the oil/water contacts in fields in many oil basins.

Proven Track Record

In the United States, CO2 EOR technologies have been demonstrated to be profitable in commercial-scale applications since the 1980s. Large-scale commercialization was demonstrated first in the Permian Basin of West Texas with the SACROC and North Cross floods in the early 1970s. The technology now has been deployed selectively throughout the world, although the Permian Basin remains the most extensive application region. These large projects inject high-purity, low-cost CO2 obtained from natural reservoirs, but an increasing percentage of natural gas byproduct CO2 also is injected. An extensive carbon dioxide pipeline network has been developed to meet the growing supply requirements of the CO2 EOR sub-industry.

There are now 111 projects in the United States that provide ±260,000 barrels of incremental daily oil production, representing slightly more than 5 percent of total U.S. crude oil production. All but five of the projects are “miscible” projects that produce ±250,000 bbl/d. Temperature and pressure conditions in a miscible flood allow the CO2 and crude oil to form a single mixture through the mass transfer of intermediate hydrocarbons from the crude oil to the CO2, versus immiscible floods, where the CO2 and crude oil phases remain distinct and separate. Since 1982, more than 1.6 billion barrels of incremental oil have been recovered using this technology, including 1.2 billion barrels in the Permian Basin.

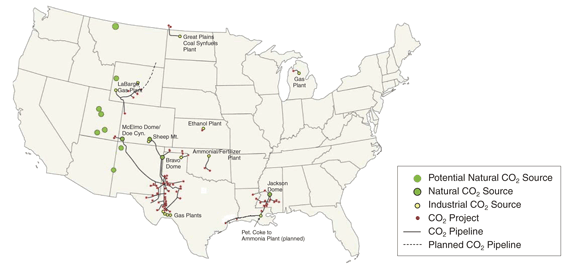

Figure 1 shows the locations of the active U.S. CO2 EOR projects (inclusive of the Weyburn and Midale projects in Canada), and includes the larger carbon dioxide pipelines and sources of supply. All together, there are 3,200 miles of CO2 pipelines carrying an aggregate volume of 3,100 million cubic feet a day (65 million tons a year).

Figure 2 tracks the steady growth in CO2 EOR production in the United States and the Permian Basin over the past 25 years. Interest in enhanced recovery has increased over the past decade in the Gulf Coast and the Rocky Mountains. Notably, growth in CO2 EOR was sustained in spite of oil price crashes in 1986 and 1998. With only a few exceptions, projects continued to operate through the periods of low prices, and amplified their CO2 purchases after resumption of “normal” oil pricing. It is significant to note that the growth of the CO2 EOR industry occurred during sub-$20/bbl oil prices, and two price crashes merely curtailed the acceleration of the growth.

A similar look at CO2 EOR production (Figure 3) illustrates that the great majority of oil has been (and is still is) produced in the Permian Basin. We believe the observable Permian Basin production decline in recent years is the result of two factors:

- The lack of a sufficient supply of carbon dioxide (or delay in getting to market) to sustain increasing project growth; and

- The maturation of existing projects that are less efficient on a per-Mcf basis, yet quite economical in today’s oil price environment.

CO2 EOR Projects

The concept of using anthropogenic carbon dioxide created as a byproduct of industrial processes for EOR is not new. In fact, the very first large-scale projects in the Permian Basin in the early 1970s effectively converted a waste stream of CO2 from natural gas processing facilities into a useful commodity by capturing, compressing and routing it through the first CO2 pipeline to the North Cross unit near McCamey, Tx., and then on to the SACROC unit in Scurry County. The response of the reservoirs to injection, especially in the carefully observed four-pattern area of SACROC, convinced several other oil companies of the technology’s economic and technical viability.

Based on the results of these early floods, plans were conceived to bring very pure (>95 percent) supplies to the region from underground natural reservoirs at Bravo Dome in northeastern New Mexico, Sheep Mountain in south-central Colorado, and McElmo Dome in southwestern Colorado. With the new supply came new projects, most notably the Wasson, Seminole and Slaughter fields–all Permian-age San Andres formation fields with 1 billion-3 billion barrels of original oil in place, and where CO2 flooding continues some 25 years after original implementation.

Outside the Permian Basin, Wyoming and Mississippi CO2 infrastructure was constructed in the 1980s. The Jackson Dome natural source field came on line in 1985 and the Shute Creek plant in western Wyoming began to capture carbon dioxide for EOR from low-Btu natural gas in the late 1980s. Both regions have continued to grow through the subsequent years. Denbury Resources is reported to be producing 900 million-1.0 billion cubic feet a day from Jackson Dome to fuel its rapid oil production growth from fields along the onshore Gulf Coast.

Other areas are seeing expansion as well. Core Energy has six projects under active flood in Michigan using anthropogenic supply from an Antrim natural gas plant. Chaparral Energy has also grown its list of projects to six in the Texas-Oklahoma Panhandle and Central Oklahoma using anthropogenic supply from ammonia and ethanol plants.

Anthropogenic Sources

Last year, 64 projects in the Permian Basin purchased a record volume of 1.7 billion cubic feet a day of CO2 for EOR. To date, more than 11 trillion cubic feet (630 million tons) has been injected, and 90 percent of that amount stored, in these projects. From 1986 to 2008, CO2 supplies to the Permian Basin EOR industry were effectively flat (gradual inclining sales), averaging about 1.3 Bcf/d.

In a market economy, the response to “short” supply is predictable: New supplies are found and added. In the Permian Basin, the early and easier additions have come primarily from natural source fields. In the future, anthropogenic sources will account for CO2 supply growth.

Unsatisfied nominations for CO2 deliveries within the Permian Basin were not a factor in EOR project operations and plans until 2005. For a while, the unmet demands after that time were not understood in a collective sense even within the industry, and were unknown or badly misunderstood outside the industry. The conventional thinking on CO2 EOR was that it was a niche industry that was destined to be small in nature, since it was challenged to compete with cheap oil from abroad.

As a result, companies with possible incremental carbon dioxide supplies were unaware of the market’s growth potential. Most of those false perceptions are changing now as reflected in interests from clean coal development companies (e.g., Tenaska’s Trailblazer and Summit’s Clean Energy projects), along with other utilities that are beginning to consider post-combustion capture projects on existing plants.

The concept of a “demand pull” for CO2 capture is gaining some traction over the commonly perceived and environmentally conceived “capture push” of climate change interests. The quantities of CO2 that can make a difference for growing EOR companies will require the large, point-source capture projects such as the Century natural gas byproduct, Tenaska and Summit plants or a utility on an existing electric power plant. Breaking the stereotype of limited EOR versus the robust and long-term demand potential of EOR is the key to commissioning such projects.

Residual Oil Zones

The success of several commercial demonstration projects in the Permian Basin is shifting the paradigm by proving that CO2 EOR can provide adequate demand to justify large-scale capture projects. Those observing the industry closely now realize that a very large part of future Permian Basin CO2 demand has to do with vertical expansion of old anchor fields. At least in the Permian, it is historically factual that the oil/water contacts were defined in the 1950s-60s based on operators’ desire to avoid the investments associated with handling large water volumes. Wells were not drilled beyond what was perceived as the oil/water contact depth to limit production of significant water volumes.

After it was postulated that oil could be produced below the oil/water contact using EOR techniques, several operators began experimenting with those intervals, or “transition zones,” using the moniker of the day. Shell extended the CO2 flood at its Denver Unit 150 feet below the oil/water contact in the mid-1990s. The Hess Corporation did the same at the Seminole Unit with two pilots. However, Hess recognized that the term transition zone did not seem to explain the distribution of oil below the oil/water contact and dubbed the 250-foot thick interval the “residual oil zone.”

Results from this early work were closely held until about five years ago, when a report sponsored by the U.S. Department of Energy explained the possible origins of these intervals and the commercial (CO2 EOR) significance of them. The net effect of this revelation has been to expand fields deeper and add new supply requirements on top of CO2 demand to develop the main pay zones.

Legado Resources is an example of a company taking advantage of this “new day” with its project in the Goldsmith-Landreth Unit. Following a detailed technical evaluation using core studies, petrophysical analysis and pilot operations, the company is dramatically increasing production at Goldsmith-Landreth by deepening wells to extend CO2 flooding from the main pay zone into the underlying residual oil zone.

‘Green Field’ Pay

Using a concept of transition zones, one would not expect to see “green field” residual oil zones, or zones with substantial residual oil thicknesses without an overlying main pay zone. However, new insights postulate that the residual oil zones in the Permian Basin are the result of Mother Nature’s “waterflooding,” which occurred long after the original basinwide subsidence and oil entrapment phase, and after the post-entrapment tectonics (uplift) in the western reaches of the basin. This resulted in vast areas being swept of their oil (referred to as hydrodynamic fairways), but leaving behind residual oil zones hundreds of feet thick, often without a main pay zone. Studies show that oil saturations in the green field residual zones are comparable to those in swept intervals within the main pay zones in existing fields.

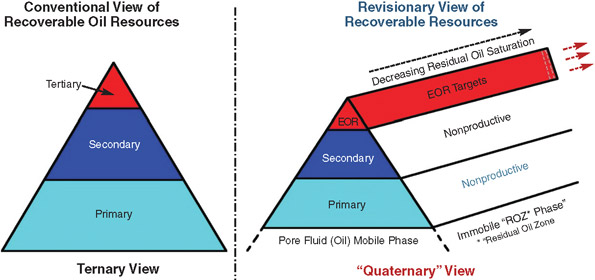

The left-hand image in Figure 4 illustrates the conventional “resource triangle” view of primary, secondary and tertiary production. The vertical expansion of anchor fields into residual zones adds a third dimension to the chart–one where EOR targets could not be exploited during primary or secondary production phases. The reason for this is that the mobile phase in the reservoir pore space is water. The oil is immobile and depends on a process such as contact with carbon dioxide to loosen it from the rock.

So what we are seeing in the Permian Basin today is a convergence of several factors to chart a new path forward in CO2 EOR. The new oil price regime, the maturation and accessibility of CO2 EOR technologies, the concerns over future oil supplies, the large targets below and between existing fields, and the environmental component of carbon dioxide storage during EOR operations all are working to paint an entirely new picture for the industry. Huge new oil resources are waiting; vast new CO2 supplies are critical.

With the stronger oil pricing environment and changing perceptions about robust targets for CO2 EOR, carbon capture companies can find themselves in a strategic position to formulate alliances and joint ventures as their projects move forward. Mature CO2 EOR regions have the advantage of proven reservoirs, and can therefore afford to pay higher prices for injectant supplies. Regions with multiple stages of tectonics need to be examined for additional reserves potential through CO2 EOR and residual oil zone storage capacities.

The upsides for this new industry include a rather unique opportunity for a joint environmental and natural resources development strategy, something very uncommon in today’s world. A business providing environmental solutions through carbon dioxide storage while also participating in a huge oil resource growth opportunity could find rewards worldwide.

L. STEPHEN MELZER is a consulting engineer in Midland, Tx, specializing in CO2 injection and enhanced oil recovery projects. With 25 years of industry experience, he formed Melzer Consulting in 1997 to advise clients in both the public and private sectors on the multifaceted business issues in the CO2 EOR, and carbon capture and storage markets. Before establishing Melzer Consulting, he operated a small independent oil and gas company. Melzer is president of the Texas Carbon Capture and Storage Association, director of the annual CO2 Flooding Conference, co-director of the annual EOR Carbon Management Workshop, and is on the advisory board for the FutureGen Project for Texas. He is a past president of the Applied Petroleum Technology Academy, and previously served as director of the University of Texas of the Permian Basin’s Petroleum Industry Alliance and as co-chairman of the University of Texas School of Law’s continuing education conferences on carbon and climate change.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.