Hydraulic Fracturing Technology

Managing Water Supplies Key To Operating Strategies In Unconventional Plays

By Keith L. Schilling

THE WOODLANDS, TX.–Oil and natural gas are the indispensable cornerstones on which the modern world is built, but it is hard to imagine a more essential natural resource than water. Although hydraulic fracturing accounts for less than 1 percent of total annual U.S. water withdrawals, water plays a critical role in well stimulation operations. Consequently, successful field operations increasingly depend on efficient and economical water management strategies, and domestic producers continue to implement innovative solutions to optimize water sourcing, logistics, treating, recycling and minimize or altogether eliminate disposal.

In step with the development of unconventional resource plays, the U.S. Energy Information Administration says the number of hydraulically fractured U.S. oil and natural gas wells has increased 12-fold over the past decade and a half, going from 49,000 to more than 600,000 wells in 2015. EIA notes that production from hydraulically fractured wells now accounts for two-thirds of total U.S. gas output and 50 percent of oil production–up from only 7 percent and 2 percent, respectively, in 2000–and more than 90 percent of all new wells drilled in the United States are estimated to require fracturing treatments.

Getting those tight reservoirs stimulated and all that production flowing to market has necessitated a corresponding increase in the amount of water pumped per well. According to the U.S. Geological Survey, median water volumes for fracturing horizontal wells increased from 177,000 gallons a well in 2000 to more than 4 million gallons for each oil well and 5.1 million gallons for each gas well hydraulically fractured in 2014.

Just as oil and gas companies invest in building out gathering systems to collect, treat and move produced oil and natural gas from the field to the point of sale, operators are focused on applying best practices and best-available technologies to source, treat and move water to the point of use in the field. In unconventional resource plays, an effective water management plan is as important as an effective field development plan, and water handling facilities have become as necessary as the pumps, compressors, separators, pipelines, etc., used to produce the hydrocarbons.

Supply Sourcing

The first challenge in water management is sourcing sufficient supplies. Economics dictate locating water sources as close as possible within a given operating area. This certainly has been the pattern when using freshwater, with operators either accessing local surface water or drilling water wells nearby. However, a key best practice being established across the industry is utilizing nonfreshwater sources when possible, including produced water, low-quality water from underground brackish reservoirs, and wastewater from industrial, power and municipal plants. The challenge is that all of these sources introduce greater variabilities in water quality and consistency, requiring careful planning, treating and processing before use in fracturing operations.

Fracturing fluid systems developed specifically for handling the high variability inherent with nonpotable water supplies make it possible to optimize water resources and minimize disposal volumes. Consider brackish water, which previously was thought to have no beneficial application. Brackish water has become a significant alternative water source in many unconventional plays.

A good example is the brackish water-bearing Santa Rosa formation located at depths of 800-1,200 feet in the Permian Basin, and hydrologically separated from shallower freshwater aquifers. Operators in the Permian Basin are drilling dedicated Santa Rosa wells and treating brackish water to remove sulfates, magnesium, iron, solids, bacteria, etc., to ensure water supplies for fracturing wells in the Wolfcamp, Spraberry and other resource plays.

In regions with limited freshwater sources, treated brackish water is proving an invaluable source. There are a number of drivers behind operators’ decisions to move to using brackish and produced water to frac wells, including economic, regulatory and environmental considerations.

Economic Sense

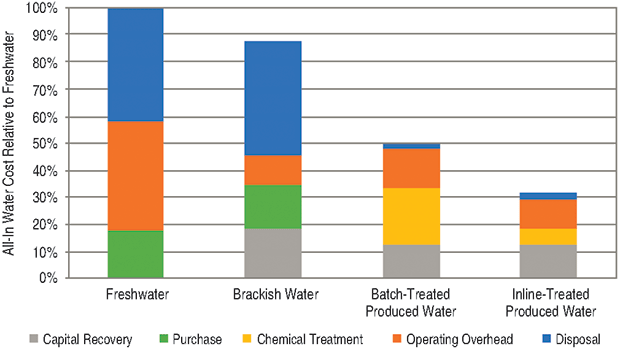

With the right infrastructure, using alternative water sources makes economic sense by resulting in less transportation and disposal costs. In fact, the total cost of alternative water sources can be significantly lower than the all-in cost associated with using freshwater, as shown in Figure 1.

Water is treated and reused locally whenever possible, enabling optimized material movement and field development planning. From the environmental and regulatory perspectives, the ability to use less freshwater, move water shorter distances, reduce truck traffic on local roadways, and limit produced water disposal volumes without harming production economics is a win/win proposition for the industry.

The specifics of source selection depend on the scale of a fracturing operation, available infrastructure and proximity to sourcing options. In the case of drilling new wells in producing fields, a strong economic case often can be made for establishing infrastructure to reuse local produced water. With sufficient scale, pad operations give operators the ability to install flexible piping and equipment to capture, treat and store flowback and produced water in relative close proximity both to where it is generated and where it will be needed to complete the next well pad.

Reusing flowback and produced water provides significant advantages with respect to economics and logistics as well as health, safety and environmental factors. Operators in the Marcellus Shale play were among the first to achieve 100 percent recycling efficiency in their fracturing operations, but the Permian Basin is probably the region where reuse efforts are most active and being conducted on the largest scale.

That said, operators in virtually every play are working on reusing flowback and produced waters, with the economics driven by the volume of water that can be recovered and the amount of treating necessary to deliver water at the rates, quality and consistency needed to support fracturing operations.

Treatment Challenges

Regardless of source, almost all water needs some form of treatment. Whether treatment is done at the source location or after transporting to storage near a fracturing site is an operator decision driven by logistics and economics. Determining the best option during the field development planning stage can optimize water resources and deliver significant saving over the life of the field.

Regardless of source, almost all water needs some form of treatment. Moreover, all water sources have their own unique chemical signatures that present their own inherent treatment challenges. Basic recommended treatment includes filtration, oil removal, biocide injection, oxidation for iron removal, and other mechanical and chemical methods. When reusing produced and flowback water, temporary storage is needed to gather and treat in preparation for reuse in frac treatments. Operators with large hydraulic fracturing operations are setting up hub-and-spoke facility designs that include local storage for produced water as well as freshwater and brackish water that can be blended for delivery to nearby pads.

All water sources have their own unique chemical signatures, and therefore present their own inherent treatment challenges. Depending on water quality and treatment method, some precipitation and scale formation typically takes place, which results in coagulation of small droplets of oil and larger solids. Basic recommended treatment includes filtration, oil removal, biocide injection, oxidation for iron removal and potentially other mechanical and chemical treatment methods, depending on water quality. In addition, brackish and produced waters often have high chloride and salinity levels that must be reduced to frac fluid specifications.

Oil removal from produced water also is required. The oil removal technology often pays for itself because of the high percentage of oil recovered from produced water streams. Some operators are seeing recoveries as high as 95 percent pure oil off produced water volumes. This process simultaneously recovers oil and minimizes trucks on the road, since this volume otherwise would have to be taken to a disposal site.

Operators must plan for the water recovered early in a well’s flowback since this water contains a mix of frac fluid, proppant and reservoir water. After completion, wells are cleaned up and the flowback water is handled separately from the produced water that follows. Operators typically do not run flowback water through production facilities because of the risk that entrained proppant will damage expensive production equipment.

Treated produced and flowback water is transferred to lined earthen pits or aboveground storage tanks to await the next stimulation job. Technologies such as double-jacketed hoses enable safe local transfer of water. Fixed piping and trucks also may be employed as defined in an operator’s field development plan.

When reusing produced and flowback water, temporary storage is needed to gather and treat the captured volumes in preparation for reuse in frac operations. Operators with large frac operations are setting up hub-and-spoke operations, which promote efficiency and cost saving. These storage designs include handling for both produced water and potentially freshwater/brackish water that can be blended with the produced water for delivery to nearby completion pads.

Water sources, frac fluids types and frac volumes are critical inputs needed for creating a detailed water infrastructure plan. The development and implementation of a forward-looking plan will increase the efficiency and reduce the overall cost of future operations.

Ensuring Quality

Delivering consistent water quality and volumes as per the frac design are key to the successful completion of a frac job. Any changes in water quality, volumes, or rates during the stimulation job may lead to screen-outs or unpredictable stimulation results.

Operators must match the characteristics of the source water with the frac treatments used. Produced water reflects reservoir geology, which in some cases, means the water is incompatible with a frac treatment. Slickwater fracs are more tolerant to produced water, but using produced water can limit the effectiveness of other frac treatment designs.

Regardless of source, almost all water needs some form of treatment. Moreover, all water sources have their own unique chemical signatures that present their own inherent treatment challenges. Basic recommended treatment includes filtration, oil removal, biocide injection, oxidation for iron removal, and other mechanical and chemical methods. When reusing produced and flowback water, temporary storage is needed to gather and treat in preparation for reuse in frac treatments. Operators with large hydraulic fracturing operations are setting up hub-and-spoke facility designs that include local storage for produced water as well as freshwater and brackish water that can be blended for delivery to nearby pads.

The industry trend toward longer lateral lengths translates to greater friction loss along the lateral and higher pressures pushing the frac down to the horizontal section. Friction reducers are crucial for making the water “slick” and reducing the pressure losses. Variations in water consistency can negatively impact the performance of friction reducers, resulting in increased pressures. These pressure increases result in reduced frac pump rates, which increase the risk of a premature frac screen-out. A screen-out leaves the borehole filled with sand, temporarily shutting down the well until it can be cleaned out.

Blending source water with fresh or brackish water with lower chloride content is a simple and cost-effective solution to water quality and consistency issues. Blending combines multiple water sources to produce a water matched to the required frac quality level. Optimally, blending must be done in real time during the frac job to ensure consistency is maintained during the entire frac operation.

Controlled automated blending technology was developed to provide on-the-fly, real-time measurements of input and output water quality. The technology continually measures output quality as well as the quality of the input water stream (i.e., conductivity related to chloride content), making adjustments in real time to match the job requirements. Automated blending and sampling/measurement can happen in real time at rates of up to 110 bbl/minute.

Striking A Balance

As part of their environmental stewardship efforts, operators are seeking to minimize HS&E exposures by having fewer trucks on the road, reducing water transfer route distances, and lowering the consumption of freshwater. The trend across the industry is toward longer laterals with more stages per lateral, resulting in larger frac jobs that pump more proppant and fluid, requiring larger volumes of water to support frac operation. Technological solutions in water treating, transfer and storage give the industry the tools it needs to cost-effectively deliver energy resources with minimal environmental impact.

Environmental stewardship is the key to the success of the upstream oil and gas industry. With their sound water management strategies, operators illustrate every day that it is possible to balance operating and environmental stewardship objectives. With the right technologies and best practices, the industry can achieve that balance in ways that also make sound economic sense.

Water management is not just a regional issue. Oil and gas companies must pay attention to larger water demands and manage resources with the big picture in mind. Every participant in the industry–from chief executives to field-level technicians–can contribute in meaningful ways to how the industry continues to balance the global need for energy with local needs for environmental safety and preservation.

In the future, the same technologies the industry is using today to treat, store and transfer water may one day be deployed to enable the use of the water produced from oil and gas operations in applications beyond the energy industry. The possibilities are endless, beginning with agriculture and ranching, but extend to any application that now relies on nonpotable water supplies.

KEITH L. SCHILLING is a senior vice president of TETRA Technologies Inc. Before joining the company in December 2014, he had served for 19 years in management, operations and engineering functions at Schlumberger. During his tenure at Schlumberger, Schilling held the positions of North American vice president of artificial lift, global personnel manager for the company’s artificial lift business, and vice president of its offshore North America wireline business. He holds a B.S. in chemical engineering from Texas A&M University and an M.B.A. from Rotterdam University.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.