Tech Trends

Parameters Define Applicability Of Unconventional Practices To Moderate-Permeability Plays

By Doug Walser

TOMBALL, TX.–The U.S. oil and gas market remains highly fluid, with operators adjusting both to the new demands of ever-changing business dynamics and the new opportunities in both conventional and unconventional plays afforded by the steady march of technology.

To demonstrate fiscal stability and long-term sustainability in unconventional reservoir development, companies are taking a number of operational and technical approaches. Many of them are obvious and involve “smart” cost control solutions, re-ranking of Tier II and III opportunities, and employing proven leading-edge drilling and completion technologies. One approach that continues to gain significant traction is targeting legacy conventional plays with the same set of technologies used during the past decade to economically develop shale gas and tight oil reservoirs. In many cases, these moderate-permeability formations were only marginally successful at the time they were first exploited with vertical wellbores.

Targeting low-performing legacy plays with newer unconventional drilling and completion processes is not an entirely new concept. Probably the best examples with clear historical verification involve the most productive unconventional plays in North America. For instance, long before the Bakken’s first commercial horizontal wells were drilled and completed in the Williston Basin, the conventional Middle Bakken sported vertical delineation and development activities solely focused on the sandy dolomite or dolomitic sand. Only when it became clear that stimulating the bounding shales above and/or below the Middle Bakken improved production character significantly did the massive development effort really take off.

The Spraberry play in the Midland Basin had been dubbed “the world’s largest unrecoverable oil reserve,” and contained thousands of marginally productive vertical wells with stacked hydrocarbon-bearing reservoirs. Various manifestations of the Niobrara in three primary basins (the Denver-Julesburg, Powder River and North Park) were produced for many years prior to the application of horizontal wellbores and high-intensity multistage fracturing techniques.

For several years, the term “unconventional reservoir” had a direct connotation with hydrocarbon source rocks, which were most often limey or sandy shales above or below existing known producing horizons. However, with continued experimentation, it became apparent that unconventional techniques were applicable in a wide and diverse set of lithological environments.

In fact, a growing body of evidence suggests that the applicability of unconventional techniques is largely independent of lithology (within limits). Recent hydrocarbon extraction efforts in the Mississippian Lime, Austin Chalk, Niobrara, Limey Eagle Ford, Bone Spring Lime and Cotton Valley all have demonstrated that other parameters besides the presence or absence of in situ source rock drive these plays’ success or failure.

System Permeability

Given that lithology may be a factor, but not a prime driver, in the suitability of unconventional drilling and completion practices, it is useful to examine those parameters that exhibit the highest influence on whether unconventional processes and technologies can be adopted effectively in an existing legacy play. Numerous studies point to permeability, degree and location of pore pressure depletion, water cut and relative degree of geological complexity as limiting parameters in the decision to target a legacy play with new processes.

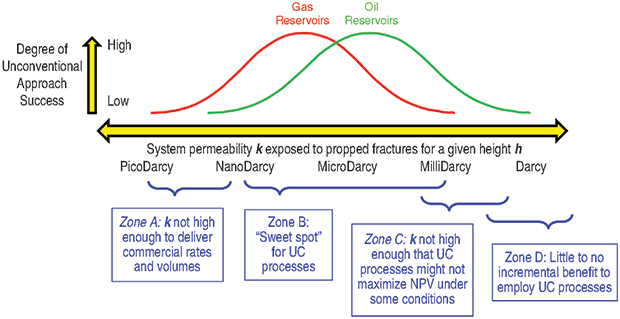

Most often, system (or weighted) permeability of the reservoir located adjacent to propped fractures constitutes the primary driver. Figure 1 visually summarizes the ranges of formation system permeability that consistently allow the successful application of unconventional reservoir development techniques. Historically, conventional drilling and completion practices focused on permeability zones C and D, and completions usually involved vertical wells and minor–if any–stimulation. Reservoirs with Zone B permeability (the sweet spot in the North American shale revolution) and Zone A either were passed up intentionally, or resulted in unsuccessful completion attempts using conventional technologies.

As operators wrap up their delineation phase in the largest unconventional plays, increasing attention is being paid to the discovery and testing of smaller legacy fields and more geologically complex reservoirs with measurable volumes of remaining reserves.

Much of the inspiration for this activity came from the successes operators enjoyed in the Midland and Delaware basins. They were drilled horizontally through reservoir volumes assumed to be drained by aging 40-acre vertical producers, but encountered substantial virgin and near-virgin pore pressures in the process. The implication is that volumes of drained acreage from vertical well extraction may have been substantially overestimated. The question has been posed often: “How did our industry miss out on the existence of such a large reserves base in North America for such an extended period?”

It may be that the answers lie in a number of legacy processes and assumptions. First, the contemporaneous technology that involved vertically penetrating horizontal layers fundamentally exposed very little total surface area of highly conductive fractures to low-permeability rock outside the wellbore. Second, the practice of establishing rigorous and relatively high porosity cutoffs from petrophysics during evaluation and analysis workflows assumed that there were zero recoverable reserves in any heights that fell outside the assigned cutoff number. Finally, the pervasive practice of obtaining permeability measurements (at atmospheric pressure) from full and sidewall cores of the highest-porosity stringers in a given column repeatedly and systemically overestimated reservoir permeability.

If typical reservoir permeability to in situ hydrocarbons is the primary driver of applicability, it follows that locating plays and positions with typical system permeabilities in the higher portions of Zone B (and lower portions of Zone C) is critical to extending the successes that operators have demonstrated in lower-permeability unconventional scenarios. The concept of system permeability refers to the weighted average permeability of all reservoir layers or stringers that may be connected to both one another and a given wellbore through a set of vertically oriented induced propped fractures.

For example, these types of plays may have individual thin stacked reservoir streaks in the high-millidarcy range, but system permeability can drop dramatically when the nanodarcy portions of the column adjacent to the propped fractures are averaged in.

Secondary Hurdles

Assuming that an operator or prospector “on the hunt” has located potential acreage positions that appear to make sense from a system permeability standpoint, numerous secondary hurdles probably remain before it is possible to employ unconventional processes and extract commercial hydrocarbons from a legacy moderate-permeability play.

The first hurdle is geological complexity. Initially, most North American legacy plays were discovered and developed using extensive geological and/or geophysical interpretations. Structural and nonstructural closures can limit the assumed overall acreage extent dramatically. It may be important to scrutinize scenarios that imply localized closure such as facies variations, unconformities, diagenetic variations or mature faulting to determine if scenarios exist whereby horizontal seals or flow barriers that inhibit hydrocarbon migration can be mitigated with longer or directionally unique lateral wellbores. In the case of stacked reservoirs cut by dip-slip faulting, it may be possible to access multiple traps with a common lateral, with only minor elevation variation.

Another challenge is to overcome misconceptions about pre-existing conventional reserves. Applying unconventional technologies to what formerly was considered a conventional play requires completely re-booting the thinking within multiple disciplines. An operator that proposes to tackle this challenge will need access to human resources skilled in unconventional reservoir, completion and production/facilities engineering, as well as a set of broadened skill sets in geology, geophysics and petrophysics. Executive management must drive a culture that actively seeks to eliminate choke points in this process.

Operators also must be aware of pressure depletion and potential water production. As noted, most underperforming legacy plays were delineated and developed with vertical wellbores. Although pore pressure depletion may not have been as severe and extensive as originally thought, it always will remain a factor. Generally, the higher the porosity the higher the permeability, and the more mature a given hydrocarbon system, the greater the chance of a debilitating water saturation scenario. Fortunately, a large percentage of serious candidate plays have sufficiently low system permeabilities (and sufficiently high irreducible water saturations) that excessive water production is not an issue.

In addition, it is important to note that a true “manufacturing” approach to operations may prove impossible in a moderate-permeability play. Many unconventional plays have huge swaths of only slightly heterogeneous reservoirs, and nice neat rows of carefully spaced horizontal laterals are common as operators move from delineation into infill development. It is highly likely that smaller legacy plays will not offer this luxury of scale and commonality, as there will be constant modifications to the exact positioning and lengths of individual wellbores. Operators intent on migrating to unconventional processes will need to account for this reality as they budget for geological, geophysical and engineering administrative resources.

A final consideration entails reserves bypassed or substantially delayed through parent-child well interactions. When long time periods elapse between the completion dates of delineation and offset development wellbores, extreme asymmetric fracturing can debilitate overall production profiles. Reservoirs with permeabilities in the “Zone C” range can be especially vulnerable to this limitation. An operator attempting to employ new technologies should expend operating or capital funds to map pore pressure variations in three dimensions across the acreage of interest.

Companies that have proven successful in endeavoring to revitalize a given position have examined each of these issues carefully and executed on plans to mitigate each and every challenge.

Prospecting Workflow

The specifics of applying a series of unconventional processes with the highest production impact will vary somewhat and depend on permeability. Statistics across North America suggest the middle portions of Zone B in Figure 1 exhibit the strongest ties between drilling, stimulation and completion processes employed and the degree of production profile success in terms of recovery factors, estimated ultimate recovery and the rate of reserve recovery.

An initial prospecting workflow would include simultaneous efforts by multiple disciplines (land and legal, geology and geophysics, engineering, and financial) primarily focused on gathering information and classifying a potential acreage position with respect to permeability range(s). Assuming a “pass,” each suggested hurdle and roadblock should be examined to determine if any single one truly constitutes a go/no-go choke point. Often, what one operator or team considers a hard choke point may be perceived as surmountable by a competitive prospector.

There are a multitude of unconventional processes and techniques that can be applied to a scenario where all hurdles have been overcome. Statistics point to some particularly impactful approaches:

- Lateral lengths can be maximized within land/legal, operational and geological constraints. It generally is agreed that remaining approximately horizontal within a potentially productive zone for extended distances increases net present values beyond what is possible for short laterals.

- Promoting and verifying the even distribution of propped fractures in each stage to the greatest degree possible often is critical.

- Propping multiple narrow induced fractures may have substantially more impact on a well’s production profile than ensuring high fracture conductivity in fewer, simpler and wider fractures. Generally, this is accomplished by using low-viscosity carrier fluids (0.5-2.0 centipoise) and small-diameter proppants (often 40/70- and/or 100-mesh).

- Achieving tight fracture spacing along the lateral can make a big difference. In any given play, an optimum stage and cluster spacing combination can be determined either by upfront measurements or experimenting with a large number of capital-intensive wellbores. The degree to which operators can take advantage of this parameter is itself permeability-dependent, whereby “Zone B” scenarios typically would duplicate current industry practice (10- to 30-foot cluster spacing), and “Zone C” reservoirs might employ spacing up to double that.

- It can be key to recognize the role of landing elevation and its relationship to proppant settling and “duning” effects. Scenarios whereby the bulk of the hydrocarbon target lies at, near or below the landing elevation often have a higher chance of being adequately propped when pumping slickwater.

- Surface efficiency can impact the cost of operations significantly. Service companies associated with North American oil and gas stimulation have made huge inroads with respect to environmentally responsible efficiency. Examples include real-time advanced engine and pump diagnostics, proppant handling and delivery logistics, and precise integration of dependent services sourced from multiple vendors.

A number of legacy conventional plays are starting to receive renewed attention in regard to their potential for responsible unconventional development, with timing that depends considerably on commodity pricing. Legacy portions of the Haynesville Shale probably top the list, followed by the Tuscaloosa Marine, the Upper Devonian/Huron, the Gulf Coast Lower and Middle Wilcox series, and the Uinta Basin. Operators in each of these moderate-permeability plays are in various stages of study and/or experimentation with unconventional techniques.

Operators and academia alike suggest that applying unconventional drilling and completion practices to conventional reservoirs does not always make fiscal sense. Indeed, it is probable that higher-permeability reservoirs may be most cost-effectively drained with vertical wellbores and attention to reducing near-wellbore skin. However, employing specific unconventional processes and techniques can dramatically improve recovery factors, EURs and the rate of recovery in legacy “borderline” plays with low to moderate permeabilities.

DOUG WALSER is a subsurface asset valuation acceleration specialist with Hydraulic Fracturing Group LLC. He has 40 years of experience in the Permian Basin, Mid-Continent, Appalachian Basin, Rocky Mountains and South Texas. He has specialized in calibrating 3-D fracture modeling using a number of methods, including historical production transient analysis and calibration by various fracture mapping processes. Most recently, Walser has specialized in methods to quantify the potential to improve the recovery factors of North American resource plays. He holds a B.S. in natural gas engineering from Texas A&I University.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.