Permian Operators Unlock Efficiency Gains And Consolidate Acreage

by Al Pickett, Special Correspondent

As of late September, the Permian Basin accounts for half the rigs active in the United States. Stacked plays, established infrastructure and skilled workers have made the Permian Basin the driving force behind U.S. oil production growth.

The region’s sustained success comes in part from the constant push to drill, fracture and produce wells more quickly and consistently. According to the U.S. Energy Information Administration, the 90-day initial production of the basin’s new wells has gone up every year since 2010.

Houston-based Coterra Energy Inc. is one of the many independent operators that is finding ways to work more efficiently. As an example, the company is developing a unique 51-well project that will allow it to conduct drilling, completion and production operations simultaneously.

“A lot of the Wolfcamp (in the Delaware sub-basin) is set up in two-mile (1,280-acre) units,” observes Michael D. DeShazer, Coterra’s vice president of business units. “Operators often have to skip around because they do not have contiguous acreage or they have midstream constraints.”

With six 1,280-acre units side by side in Culberson County, Tx., Coterra’s Windham Row project will not face those challenges.

“It is a half-billion dollar investment,” DeShazer says. “We will drill a well. As soon as the rig moves far enough away, we will come in with a frac fleet to complete the well. And then as soon as the frac crew moves far enough away, we will start producing the well. Eventually, we will develop 51 wells in a row from east to west. So we will be drilling, completing and producing wells at the same time all in the same block.”

Coterra, which has a joint development agreement with Chevron on the project, can bring wells on line quickly because it controls the water and gas midstream infrastructure that is servicing the project, DeShazer says.

“We believe Windham Row will save 5%-10% on what is already a low-cost area,” he calculates.

Most of the project’s 51 initial wells will be drilled and completed in 2024. DeShazer says the company has finished a similar but smaller project, Mint Julep Row, successfully before moving south to begin the Windham Row project.

“We are excited,” he offers. “We know the area well and have executed similar projects, which reduces risk.”

DeShazer adds that Windham Row provides plenty of running room. “We are targeting the Upper Wolfcamp for the first 51 wells, but we can come back in and develop other zones utilizing much of our existing surface infrastructure,” he explains. “The Harkey (Bone Spring) is above the Wolfcamp, and there is the Lower Wolfcamp. These are great opportunities for future development.”

To reduce fuel costs and emissions, Coterra is using electric drilling rigs and electric frac fleets on the project, DeShazer mentions. Instead of creating electricity with natural gas or diesel-powered generators, Coterra simply plugs into the grid.

Going Electric

DeShazer recalls making a presentation in 2013 with the title “Building an Oil Field on the Moon.”

“Back then, the only things around Orla (in Reeves County, Tx.) were cattle guards,” he chuckles. “Now there are two gas plants and man camps. It is amazing to see. There was one substation that had previously serviced an old sulfur mine. When we called Oncor, the electric service provider in that part of West Texas, to discuss using the substation, they were surprised because they hadn’t sold any electricity from that substation in years. Since then, we have built our own substations.”

Coterra Energy Inc. is running six rigs and two hydraulic fracturing fleets in the Delaware Basin, including an electric drilling rig and an electric frac fleet. The company indicates its acreage contains 15-20 years of future drilling opportunities.

DeShazer says it’s relatively easy to use grid power in Texas because most of the acreage is private land. “In New Mexico, the electric grid is controlled by different co-ops, so it is more difficult to extend lines,” he contrasts. “There are a lot of operational issues.”

Since Texas has its own power grid, long-term demand growth can present a challenge, DeShazer acknowledges. However, the state has made considerable progress in defining essential services and how electricity gets to the substation since the great statewide power outage during Winter Storm Uri in 2021.

Coterra has more than 300,000 acres in the Delaware Basin in Eddy and Lea counties in New Mexico and Culberson and Reeves counties on the Texas side of the border. DeShazer says the company produces 223,000 barrels of oil equivalent a day in the Delaware Basin, 70% of which is liquids. He points out that the liquids percentage includes natural gas liquids.

“NGL value is huge in the Permian,” he contends. “The Delaware Basin is gassier than the Midland Basin. Even though it is not as oily, the gas gives us the opportunity to lift more efficiently, making production costs much lower than in the Midland Basin.”

DeShazer predicts that Coterra has at least 15-20 years of future drilling opportunities. As of late September, Coterra has six rigs and two frac fleets operating in the Delaware Basin, with one electric drilling rig and one electric frac fleet running in the Windham Row project.

Coterra also operates in the Anadarko and Marcellus basins. Citing strong well performance during the second quarter, the company in early August raised its full-year production guidance for 2023 to 630,000-655,000 Boe/d, a 2% increase.

Three-Mile Laterals

Two-mile laterals have become commonplace in the Permian Basin, DeShazer notes. While they likely will continue to be the mainstay, he says longer laterals can offer attractive economics.

In mid-April, Coterra completed a four-well project in Reeves County with three-mile laterals. The wells delivered stronger flowback than expected, with production exceeding projections, DeShazer relates.

“We were excited that the IP rates were higher than expected,” he says. “Initial production rates can be depressed on three-mile laterals because the extra oil and gas the additional length provides has to go up the same pipe as the rest of the production. There also are faulting and geologic differences in this area that come into play with longer laterals.”

Even so, DeShazer says the extra lateral length can be worthwhile. He explains that the cost for the well’s vertical section remains the same, even though going from two to three miles increases the producing lateral length by 50%. In practice, that means the three-mile lateral can yield a 10%-15% cost savings for every gross perforated interval.

Despite the compelling economics, DeShazer says three-mile laterals will remain uncommon in the Delaware Basin because most of the drilling units were established with two-mile laterals in mind.

Efficiency Gains

Drilling longer laterals is but one of many ways that Permian operators are increasing efficiency. The basin’s players have been so successful that in its August Short-Term Energy Outlook, the U.S. Energy Information Administration projects that the Permian’s crude oil production will increase 430,000 barrels a day in calendar year 2023.

Amazingly, that number exceeds EIA’s forecast (410,000 bbl/d) for the entire Lower 48 because “production declines in other regions offset some of the forecast growth in the Permian Basin.”

On Sept. 22, Baker Hughes reported that the Permian Basin had 317 rigs, 27 fewer than were active in the same period a year ago.

In other words, “well productivity has offset the decline in active rigs so far in 2023,” according to the EIA.

“That speaks volumes to the quality of rock in the Permian Basin,” says Hodge Walker, chief operating officer of Civitas Resources, “and it is a testament to the innovation and creativity of the industry.”

New Kid on the Block

Civitas Resources is a newcomer to the Permian Basin, having just closed an agreement on Aug. 2 to acquire oil producing assets in both the Midland and Delaware subbasins.

“It is a new entry for Civitas as a company, but many members of our leadership team have experience in the Permian,” Walker notes.

The Denver-based company has long operated in the Denver-Julesburg Basin of Colorado.

Civitas Resources has entered the Midland and Delaware basins by acquiring 68,000 net acres from Hibernia Energy III LLC and Tap Rock Resources. Like the company’s existing assets in the Denver-Julesburg Basin, Civitas says its Permian acreage offers attractive returns and low breakeven costs.

“The top breakeven basins in the country are the DJ, the Midland and the Delaware,” assesses Walker. “Entering the Permian makes Civitas a better company. It adds value, and scale matters from a capital standpoint.”

The transactions involve acquiring assets from Hibernia Energy III LLC and Tap Rock Resources from funds managed by NGP Energy Capital Management LLC for a total consideration of approximately $4.7 billion. According to Walker, they enhance Civitas’ strength and sustainability by bringing it into the heart of the Permian Basin and expanding its inventory of high-return drilling opportunities.

The combined transactions add about 68,000 net acres (90% held by production) in the Midland and Delaware basins with total proved reserves around 335 MMboe.

Walker says the transaction will increase Civitas’ existing production by 60% by adding approximately 100,000 boe/d (54% oil) of current production. “The acquisition will add about 800 gross locations, which gives us the next decade of high-quality targets,” he continues.

Civitas has seven rigs running in the Permian—four in the Delaware Basin and three in the Midland Basin.

Civitas’ acquisition of Hibernia’s Midland Basin assets includes 38,000 net acres in Upton and Reagan counties that produced 41,000 boe/d (56% oil) during the first quarter, Walker describes. He says the transaction gives Civitas 450 high-quality locations on contiguous acreage.

The Tap Rock deal provides Delaware Basin assets, including 30,000 net acres primarily in Eddy and Lea counties, as well as a small position in Loving County, Tx. During the first quarter, the acreage produced 59,000 boe/d (52% oil), Walker says. He estimates that it contains 350 high-quality locations.

Walker mentions that Hibernia and Tap Rock’s programs have been largely successful.

“We will be leveraging their skill sets,” he says. “We will optimize development and see how we can improve using what we have learned in the DJ Basin. A big part of this is integration. We have a six-month service agreement with Hibernia and Tap Rock to bring them into the larger Civitas.”

The service agreement will run through February. Walker says Civitas plans to operate the assets with the same philosophy it practices in the DJ Basin: generate free cash flow and strong shareholder returns while maintaining a strong balance sheet and achieving carbon neutrality.

Transformative Transactions

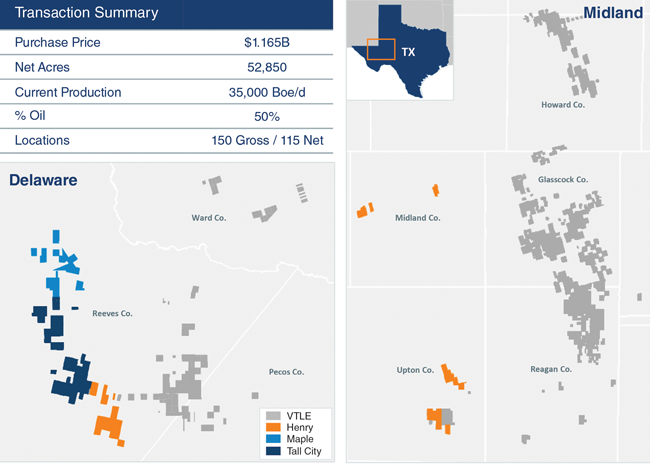

Tulsa-based Vital Energy announced on Sept. 13 that it had reached definitive agreements on three separate transactions in the Permian Basin for total consideration of $1.165 billion. The combined transactions will add nearly 53,000 net acres containing 248 million boe in proved reserves (44% oil).

The additional acreage will bring Vital’s total position to 250,000 net acres and increase its current production approximately 35,000 boe/d (50% oil), Vital says. According to the company, this increase takes its estimated average daily production for 2024 to 112,000 boe/d, 25% beyond standalone expectations. The transactions’ effect on oil production is even greater, with estimated average full-year 2024 production rising 30% to 55,000 bbl/d.

Through transactions with Henry Energy LP and Henry Resources LLC, Tall City Property Holdings III LLC and Maple Energy Holdings LLC, Vital Energy is adding 53,000 net acres to its Permian Basin position. The company says the scale and capital efficiencies made possible by these acquisitions will help increase free cash flow by 90% next year.

“These transactions are truly transformative for us,” comments Jason Pigott, Vital’s president and chief executive officer. “Ever since I got here (in 2019), our goal has been to build scale, be successful in growing our oil production, pay down debt and move toward returning cash to our shareholders. These transactions check all the boxes. This is the biggest deal we have done, and we are thrilled.”

The transactions have allowed the company “to change our whole financial structure,” according to Pigott. He indicates that once the deals close, Vital will direct almost all its free cash flow to reducing debt, allowing it to achieve pro forma leverage, at $80 a barrel WTI, of less than 1.0x net debt/consolidated earnings before interest, taxes, depreciation, amortization and exploration expenses by year-end 2024.

The sellers were affiliates of Henry Energy LP and Henry Resources LLC; Tall City Property Holdings III LLC; and Maple Energy Holdings LLC.

Vital agreed to purchase substantially all of Henry’s Midland and Delaware Basin assets in an all-equity transaction consisting of 3.72 million common shares and 4.54 million shares of perpetual mandatorily convertible preferred securities. Pigott says the Henry family will retain a nonoperating position.

Vital indicates it is purchasing Tall City’s Delaware Basin assets for $285 million in cash and 1.58 million common shares. It also is purchasing Maple’s Delaware Basin assets in an all-equity transaction consisting of 3.31 million common shares.

The three recent transactions are merely the latest acquisitions for the company, Pigott mentions. “We have made five transactions (all in the Permian Basin) in the last six months for $1.7 billion,” he notes.

What makes the Permian so attractive?

“We like the Permian because it has the highest rate of return wells,” Pigott replies. “It also allows us to have an oil cut greater than 50%. By being oilier, we can create high returns that can withstand downturns in commodity prices.”

In late September, Pigott said Vital would continue running Henry’s one rig plus its own three rigs. Vital’s three rigs will remain divided between the Midland and Delaware basins, with two in the Midland and one in the Delaware. The Henry rig will drill about 70% of the time in the Delaware Basin and 30% in the Midland.

Prior to the transactions, most of Vital’s activity in 2023 has been in Howard County in the Midland Basin. “But we will have 20 wells coming on early next year in western Glasscock County,” Pigott says. “So next year, our Midland Basin activity will be about 25% in Howard County and 50% in western Glasscock County, with the remainder in our Driftwood position in the southern Midland Basin.”

Pigott points out that Henry’s acreage is adjacent to Vital’s Driftwood position. “It fits like hand in glove,” he remarks.

Artificial Lift

About 80% of Vital’s Howard County wells are producing with electric submersible pumps, Pigott relates. Vital plans to keep ESPs on those wells for nearly two years until production flattens out, at which time they will move to gas lift and then rod pumps.

Thanks to improved efficiencies, the company’s base production has exceeded expectations by 10% over the previous year. Vital achieved a 15% uptime increase on wells using gas lift and 3% on all other wells, Pigott details.

“These transactions increase our scale in the Permian and fit with our proven strategy of creating value through disciplined acquisitions,” he says. “We have demonstrated our ability to effectively consolidate Permian assets and identify sustainable synergies to lower costs, improve margins and enhance free cash flow. These acquisitions will significantly strengthen our free cash flow outlook and enable us to rapidly de-lever our balance sheet.”

He says the acquisitions and optimized development will increase Vital’s 2024 free cash flow by approximately 90%, strengthen the company’s capital structure and add about 150 high-value locations with a breakeven price around $50 a barrel.

Expanding Footprint

Permian Resources Corp. announced in its second-quarter earnings report that “efficient development of its core Delaware Basin acreage position in the second quarter (is) delivering strong well results and driving meaningful operational efficiencies.”

Co-Chief Executive Officer Will Hickey says those operational efficiencies add up to substantial savings. “We recently reduced our operated rig count from seven to six rigs due to continued efficiency gains and remain on pace to achieve our full-year and fourth-quarter production targets, highlighting the strength of our operations,” he states.

During the second quarter, the company’s average daily crude oil production increased 8% compared with the prior quarter to 83,393 barrels of oil a day. Second-quarter total production also increased 8% quarter-over-quarter, averaging 165,850 boe/d.

The company adds that it achieved meaningful improvements in drilling and completion cycle times. Average feet drilled a day increased 13% from the third quarter of 2022, while the average feet completed rose 31%, the report details.

On Aug. 21, just 19 days after releasing its second-quarter earnings, the company announced it would acquire Earthstone Energy Inc. in an all-stock transaction valued at approximately $4.5 billion, inclusive of Earthstone’s net debt.

According to the announcement, the transaction “strengthens Permian Resources’ position as a leading Delaware Basin independent producer and increases our Permian position by approximately 223,000 net acres with over 400,000 net acres, pro forma production of approximately 300,000 boe/d and an enhanced free cash flow profile.”

“We believe the acquisition of Earthstone represents a compelling value proposition for our shareholders and strengthens our position as a premier Delaware Basin independent,” Hickey affirms. “Earthstone’s Northern Delaware position brings high-quality acreage with core inventory that immediately competes for capital within our portfolio. Additionally, we have identified numerous ways to leverage our deep Delaware Basin experience and incremental scale to improve upon these assets across the board, including $175 million of annual synergies.”

In the Delaware Basin, the acquisition adds approximately 56,000 net acres of high-quality, stacked pay reservoirs, largely offset to Permian Resources’ existing acreage in Lea and Eddy counties. Earthstone’s remaining acreage is located in the Midland Basin.

Endeavor Energy Resources reports it has partnered with Select Water Solutions to complete one of the largest produced water recycling projects ever in the Midland Basin. Across a month, the project delivered more than 8.2 million barrels of produced water to four hydraulic fracturing fleets operating in Martin County, Tx.

Water Recycling

In the semiarid Permian Basin, recycling produced water has become an important component of the equation for fracturing large horizontal shale wells. Endeavor Energy Resources, which holds approximately 360,000 net acres in the Midland Basin and 500,000 net acres total, announced on Aug. 14 that it had completed one of the largest recycled produced water jobs recorded in the Midland Basin.

The project, a joint effort by Endeavor and Select Water Solutions Inc., involved four frac fleets in Martin County. According to the companies, it achieved recycling and delivery rates as high as 300,000 bbl/d of water. In total, more than 8.2 MMbbl of produced water were recycled at Select’s Big Spring Recycling System, in Howard County, Tx., and transported to Endeavor’s pad site during the monthlong project.

“Being a good steward of the environment and of our natural resources is important to Endeavor and our affiliate companies,” says Endeavor Chief Executive Officer Lance Robertson. “Select has been a great partner and shares the same view when it comes to responsibly producing oil and gas in our region. We are particularly proud of working together to reduce our dependency on freshwater and conserve natural resources while providing reliable energy for America.”

The recycled produced water was sourced from six regional operators within a 10-mile radius of the Big Spring Recycling System. Select indicates it has sustainably delivered the recycled water using electric pumps along an underground, 24-inch pipeline spanning from Howard County to Martin County.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.