Production Optimization

‘Systems’ Approach Optimizes Pad Production And Storage Operations

By Michael Machuca

HOUSTON–An overall systems approach to continually monitoring, controlling and optimizing critical operations on well pad facilities can help operators minimize lost and/or unaccounted for production. Specific technical solutions associated with critical operations include tank vapor control, vapor recovery units (VRUs), inventory monitoring and management, manual tank gauging, custody transfer, and remote operations.

Ineffective management of well pad inventory and off-site transfers quickly contributes to significant uncertainty in production fluid management and accounting. Efforts to improve operations may involve a complex process of identifying, sourcing and integrating individual critical operation solutions that may not fully address operator needs for capital efficiency, standardization, reliability, or effective field support.

Monitoring and optimizing critical operations on a daily basis from an overall system perspective deliver a number of benefits. Timely insight into fluid handling and transfers helps achieve daily production targets while ensuring measurement compliance. Vapor control and recovery reduces hydrocarbon emissions and lost production. A standardized systems approach to applying integration helps maximize capital efficiency and cash flow against escalating facility and operating costs.

Best practices and experiences from various operators provide insight into the challenges, technology applied, and potential/actual benefits realized in terms of operations and field development. This includes developments to improve the reliability of vapor recovery, incorporate application-specific software, and implement a modular approach for remotely managing production storage operations (Figure 1A).

Systems Approach

In shale resource development projects, drilling and completion efforts largely have driven efficiency improvements. The focus has been on cost and time to first production, which limits oil and gas companies’ ability to focus on operational efficiencies. Efforts to standardize modular facility designs have not always exploited automation opportunities for standardized operations and production optimization.

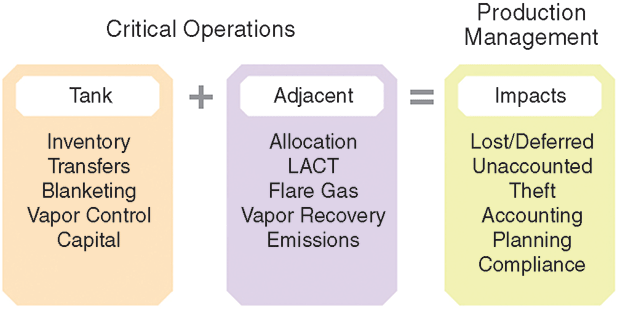

Variability in pad production storage management in conjunction with adjacent production-related operations can be linked to multiple production issues. Gaining insight and managing these various parameters from a systems approach improve operational effectiveness and reduce overall production uncertainty.

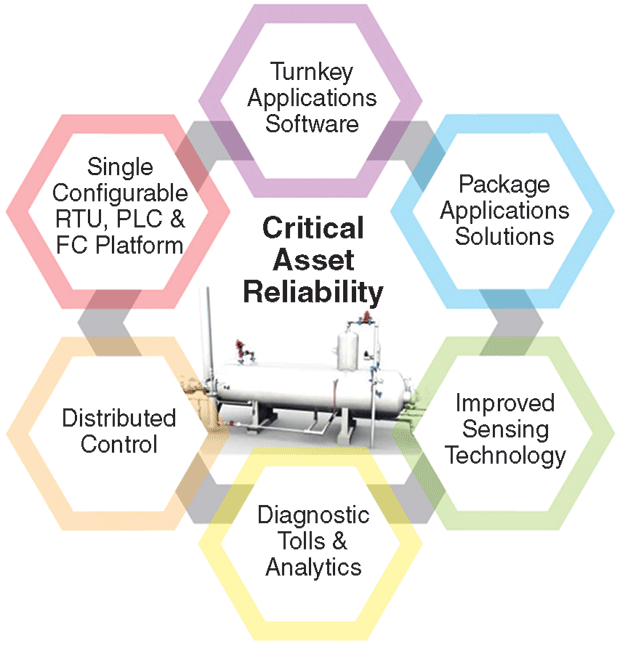

Advances in remote automation technology, combined with a focus on solving critical field asset challenges, are expanding the remote automation systems approach to monitoring, controlling and automating operations, as illustrated in Figure 1B.

Improved sensing technologies make it easier and more cost effective to monitor and control critical parameters. At the same time, the expanded functionality of remote operations control platforms, scalability, and distributed architectures reduce the complexity associated with system integration. Packaged-application solutions consolidate monitoring and control data to enhance the optimization of process units and modular skid systems. Turnkey application software provides configurable software modules to support customization, standardization, and automation of critical operations.

Pad production storage management offers a number of opportunities to implement integrated applications and system-based solutions to address the various challenges associated with overall production management. This includes critical operations associated with:

- Inventory, allocation and custody transfer management;

- Inventory and fiscal transfer measurement;

- Vapor control; and

- Vapor recovery.

Reducing Uncertainty

Managing well pad inventory, allocation and custody transfer encompasses multiple operations that contribute to overall uncertainty in production management. The accumulated measurement errors and variability in operations within a storage system can add quickly to a significant level of uncertainty. Higher levels of uncertainty reduce the prospect for timely insight into problematic field operations, which translates quickly into added lease operation costs and lost revenue.

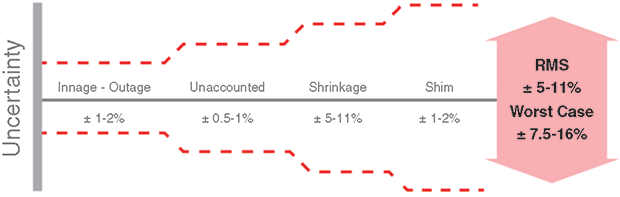

Figure 2A depicts how quickly various operations can contribute to overall production uncertainty. Manually gauging the accuracy of tank “in” and “out” volumes is highly dependent on operator competency and consistency in sometimes challenging weather conditions. Rounding off open- and end-level measurements to ensure contractually compliant haul volumes introduces unaccounted-for errors. Poor insight into actual oil shrinkage and oil losses in water storage tanks also contributes to overall production uncertainty.

The root mean-square error of the typical values encountered in the field indicates a potential uncertainty of 5-11 percent. It should be noted that each operation is prone to uncertainty creep and operational bias, which can lead to a worst-case uncertainty in the 7-16 percent range. One operator’s efforts to verify the extent of measurement variability within a team of gauges indicated volume discrepancies were actually as high as ±8 percent.

Uncertainty in production measurement can represent substantial fiscal risk. Consider, for example, the potential economic impact of a 1 percent error in tank gauging on a typical shale well pad that averages 900 barrels a day and requires five truck hauls a day (180 barrels each). At an average oil price of $50 a barrel, a 1 percent tank gauging error would amount to an annual fiscal exposure of $164,000. At $70 oil, it would be $230,000 a year. Even $30/bbl would equate to $95,000 on an annual basis.

In one case, a shale field development with 3,000 hauls per month estimated annual losses and exposure to be more than $19 million.

Deploying tank management software and remote operation control technology provides the means to automate various operations to manage and minimize production uncertainty. It allows automated integration of truck hauling operations and reporting, well production measurements, level-based gross volume inventory and custody transfer measurements.

In one shale operation, total unaccounted-for uncertainty was determined to be ±15 percent. Integrating the various monitoring, control and operation components as a system involving turnkey applications software reduced that uncertainty to ±1 percent after 60 days.

The primary contributors to this improvement were:

- Increased accuracy in level-based gross volume inventory, including shrinkage;

- Timely pay/check haul verifications using flow and level measurement; and

- Improved allocation of hauled fluids back to the wellhead.

Inventory Measurement

The fundamental operational concerns associated with well-pad tank storage can be categorized as ensuring containment, managing oil and water inventories, and measuring intertank and off-lease volume transfers.

Applying wired or wireless sensing technology for continuous and point-level monitoring improves production management by enhancing operations in all three categories. Continuous insight into actual inventory levels helps avoid reactive operator events associated with high level alarms, well shut ins, or tank overfill situations.

Oil losses to water storage tanks and diminished storage capacity caused by excessive water levels in oil tanks are minimized by detecting oil/water interface. It also validates well production rates, off-lease transfers of produced water, and tank gauging operations for oil custody transfer.

Integrating this functionality into automated production management programs has proven to eliminate issues around well allocation, unaccounted-for or lost production, and production measurement compliance.

Combining continuous well production flow measurement with level-based volume inventory has allowed a number of operators to shift to comingled allocation versus dedicating a line of tanks to each producing well. The potential reduction in tanks varies from 20 to 55 percent, depending on the facility architecture. In one case, well-pad tankage was reduced from 24 to 19 units. Based on the installed cost of the tanks, piping, valves and monitoring equipment, this equated to a potential capital savings of $70,000 a pad.

The lack of insight into oil skim in water storage tanks also can be a reasonable contributor to lost revenue opportunities. Unaccounted-for or unauthorized hauling of produced oil in water from a multiple-well pad can reach more than $1 million a year in lost revenue, if not accurately monitored and recovered.

Again using the example of a pad averaging 900 bbl/d in production, a 1 percent loss from oil skim in water storage tanks would represent nine bbl/d, or $270/day ($98,500/year) at $30 oil, $450/day ($164,000/year) at $50 oil, and $630/day ($230,000/year) at $70 oil.

Although manual tank gauging can be a lower-cost alternative for off-lease custody transfer measurement, it presents a number of health, safety and environmental concerns associated with frequent field trips, working under harsh seasonal weather conditions, and cumulative exposure to volatile organic compounds. This, combined with sustaining contractual custody transfer measurement uncertainties, is prompting operators to consider lease automated custody transfer systems as an alternative.

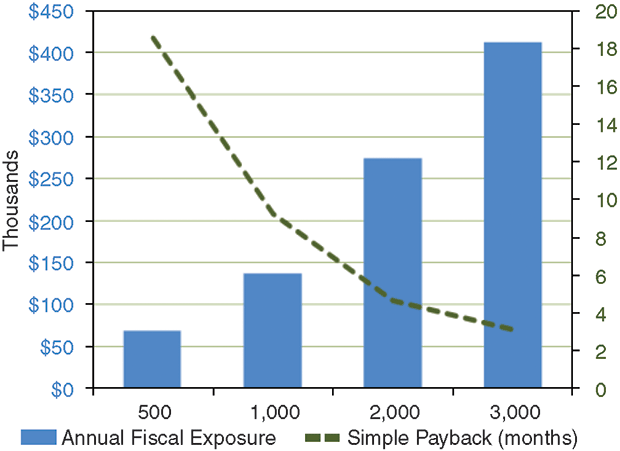

An overall gauging uncertainty of ±1 percent compared with LACT uncertainty of ±0.25 percent reduces fiscal exposure and provides a means to validate the measurements against periodic proving. Figure 2B provides the simple payback for a fully equipped 3.0-inch LACT unit at $50 oil in relation to a 0.75 percent reduction in fiscal exposure against the capital, installed and first-year proving costs.

Operator feedback on when it is viable to implement LACT systems varies from 200 to 1,000 bbl/d production, which depends on actual gauging uncertainty experienced in the field. For example, a gauging error in the 2 percent range reduces the payback for a 500 bbl/d well pad by more than 50 percent.

Vapor Control

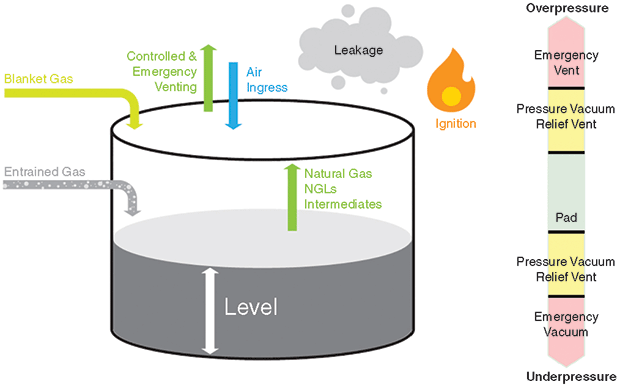

Vapor control is a balancing act against the various operating variables shown on the left-hand side of Figure 3. Storage tank filling and pump-out operations, various sources of natural gas, flashing of light-end hydrocarbons, and leakage points make it challenging to ensure controlled containment. Overpressuring increases natural gas losses normally used to generate production revenue. Introducing oxygen and water into the head space as a result of a temporary vacuum can lead to an explosive gas mixture forming in the tank and can reduce tank integrity because of accelerated corrosion.

The image on the right-hand side of Figure 3 illustrates the three primary control stages. The first stage of vapor control incorporates a supply gas pressure regulator to control the vapor space during pump-out operations or when temperature changes decrease the head pressure.

In the majority of upstream applications, the pressure vacuum relief vent initiates a controlled venting of gas because of increased head pressure from filling operations. A controlled release also will occur in situations where the head pressure is increasing because of changes in temperature, flashing, or unexpected entrained gas in the oil inflow. A controlled intake of atmospheric air is implemented to counter supply-regulator problems in meeting the gas demand, resulting in a vacuum.

An emergency pressure vacuum relief vent is the third component for vapor control, should abnormal operations or control component failures result in a rapid change in pressure that exceeds tank design specifications, which typically would occur in an emergency such as fire or lightning.

To establish an effective control regime, it is important to minimize any potential for the different components to overlap in their control function. Field-based best practices show components with low threshold operating pressures, accurate control, fast speed of response, and operating stability provide reliable, sustainable vapor control. Ensuring each component is tested and/or certified to meet minimum operational leak rates, in combination with self-reseating and sealing gauge hatches, also helps establish a stable control environment.

Natural gas vapor losses associated with flashing, ineffective gas blanketing, and leak sources are hard to quantify. However, utilizing a Bakken well pad configuration and production characteristics (36 tanks per pad and 40-degree API oil), the ASME 2001 calculations for a small-bore gas orifice were used to determine losses based on an individual tank leakage rate equivalent to an 0.25-inch orifice plate. Depending on the tank head pressure, the lost revenue potential for the well pad can reach $400,000 annually, based on a market price of $3.00/Mcf, $267,000 at $2.00/Mcf, and $534,000 at $4.00/Mcf.

VRU Technology

Increasing regulatory compliance and potential lost production has prompted a number of shale-play liquids operators to implement various technologies to recover the Btu-rich vapors from storage tanks. This includes compression units to redirect the vapor into the natural gas sales pipeline.

Although the added revenue from vapor recovery units can be significant, so can the potential total cost of ownership associated with conventional compression technology. System reliability or downtime, added operator intervention, ongoing repair and replacement costs, and energy usage are some of the concerns expressed by operators in implementing a viable economic solution.

The added challenge of federal and state regulatory agencies enforcing 95 percent recovery efficiencies and regulatory compliance reporting emphasize the need for viable vapor recovery solutions.

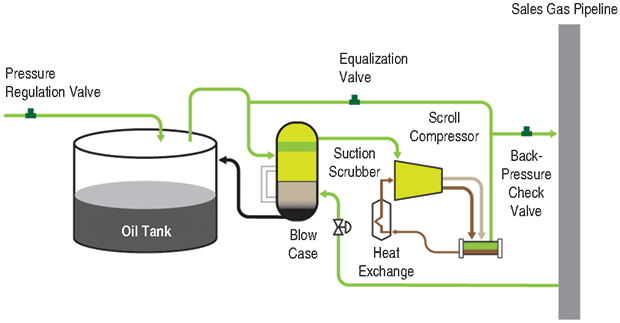

Scroll compressor technology that is common in industrial refrigeration and air conditioning applications is making its way into the shale oil and gas production segment as part of VRU systems (Figure 4). The compressor design consists of a fixed scroll mounted on the compressor casing and an orbiting scroll that is coupled to the crankshaft. The orbiting motion creates a series of gas pockets travelling between the two scrolls. The outer pockets draw in the gas, which in turn, is compressed as it is moves to the center of the scrolls.

This design reduces the number of moving parts, provides higher efficiency over its operating range, and allows operation under a 0-100 percent duty cycle. The hermetically sealed unit eliminates shaft seals, thereby providing a zero VOC emissions rating.

A scroll compressor-based VRU skid includes a number of interesting design features, such as a heated multistage gas/oil stabilizer to inhibit the dilution of lubrication oil with natural gas liquids. Combining this feature with a low oil carryover (<1.0 parts per million, independent of flow) and an eight-gallon oil reservoir help reduce annual maintenance programs.

System control is based on programmable application software that utilizes gas composition data to adjust operations for maximizing NGL recovery. The fixed displacement volume of the scrolls and rpm provide a gas-recovered volume measurement. This is included in an automated compliance report detailing operating parameters, fault, and available time reporting.

A supervisory control and data acquisition interface also has been tested for remote monitoring to facilitate preventive maintenance programs within the operating company, or as a third-party service program.

Field trials initiated in the Eagle Ford and Bakken plays included a “quad” design to facilitate adding or removing compression modules to accommodate changing pad production. Overall operations indicated a high level of mechanical readiness and reduced overall maintenance and operating costs. The results indicate recovery efficiencies exceeding 95 percent, oil-related maintenance costs reduced by 90 percent, and up to 50 percent lower energy costs. Simple payback on a 96 Mcf/d installation, assuming $2.95/Mcf market value, is slightly less than 12 months.

Integrating and automating critical operations associated with pad-production storage management while supporting the need for standardization and production optimization can be challenging. Advances in remote automation and sensing technology, combined with modular applications software, provide turnkey solutions to minimize the challenges in a cost-effective manner.

MICHAEL MACHUCA is director of North American upstream oil and gas marketing at Emerson Process Management. He has been with the company since 2005, supporting the implementation of Emerson solutions in oil and gas applications. Prior to joining Emerson, Machuca worked for seven years designing oil field equipment, mostly for subsea applications. He holds a B.S. in mechanical engineering from the University of Houston.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.