Water Management Strategy Key To Newfield’s Success In Mid-Continent Resource Plays

By D. Steven Tipton

TULSA–Water is the most commonly used fluid in the oil and gas business, making its usage and management critical to the petroleum industry. More than ever, in fact, water is an integral part of the success of oil and gas operations. Without adequate supplies of water, there is no multistage hydraulic fracturing, and without fracturing, there are no oil or gas resource plays. And of course, without resource plays, the trend lines on domestic oil and natural gas supplies would look very different.

In every jurisdiction in the country, water use is regulated in some manner, although the regulation and ownership of water is different in each oil- and gas-producing basin. In many areas, the use and handling of water have become emotionally charged.

Newfield Exploration Company is committed to responsible environmental stewardship. As part of that broader commitment, Newfield has developed water management best practices for its stimulation programs that are designed to minimize the impact of drilling and completion operations on the environment. Going forward, Newfield will continue to build and improve on its water management approach as the company develops its lease positions in unconventional domestic resource plays–from the Eagle Ford and Cana Woodford, to the Bakken/Three Forks and Granite Wash.

This article concentrates on Newfield Exploration’s water use and reclamation strategy for stimulation programs in its Mid-Continent area, including the Granite Wash tight oil and gas reservoirs in the Anadarko Basin, the Woodford Shale gas reservoirs in the Arkoma Basin, and the Cana Woodford oil reservoirs in the Anadarko Basin. At the time Newfield established operations in each area, little or no infrastructure existed. As the drilling programs progressed, infrastructure has been built to support our drilling and completion operations.

All operators conducting drilling and completion operations use some type of water management cycle (Figure 1). An operator must first locate and acquire the water needed for the operation it is performing. In Newfield’s case, groundwater is the primary source of water for the Granite Wash. Surface ponds that collect runoff are used for the Woodford Shale. A combination of groundwater and surface water obtained from sources such as ponds and creeks is being used for the Cana Woodford.

No matter what water source is used or the quality of the water, it must be transported to a storage facility for use during drilling and completion operations. Freshwater typically is pumped through aluminum, poly pipe, PVC pipe and lay-flat hose, or trucked to a storage or well site, while recycled and produced water is pumped through poly pipe or lay-flat hose, or trucked to a storage site.

Since water is the base fluid for most drilling muds and hydraulic fracturing fluids, it must be stored near the well operations in sufficient quantities to complete a job in a manner that is both economically and environmentally sound. The primary use for water, of course, is hydraulic fracturing during well completion. Newfield’s fracturing designs range in size from 100,000 to 500,000 barrels of water per well. The completions generally are pumped at rates from 80 to 100 barrels a minute.

Depending on the soil conditions and the type of fluid being stored, both lined and unlined in-ground storage pits are used for the majority of our completions. In areas where water is recycled, there must be enough local storage capacity for both flow back or produced water and processed clean water.

During the completion operations, water is pumped from the storage facilities to the well site. Once on site, the water is stored in frac tanks and subsequently mixed with proppant and other chemicals before being pumped down hole to hydraulically fracture the reservoir. Flow back begins after the well has been fractured and clean-out operations are under way. The flow-back water is separated from any hydrocarbons at the well’s test or production facilities, and then is pumped or trucked to a recycle pit or disposal well (Figure 2).

At the recycle facility, the flow back and/or produced water is processed and cleaned for reuse. The amount and type of water processing that is required depends on the quality of the water produced from the well(s) and the type of fluid being used for the fracturing operation. The water that is not reused is pumped into a disposal well.

Granite Wash

Newfield’s Britt Ranch and Briscoe fields were drilled for deep Morrow gas during the 1980s. The Morrow in western Oklahoma and the Texas Panhandle is a conventional gas condensate reservoir. The Granite Wash in the same area is composed of very tight, laminated reservoirs that produce both oil and gas. From 2001 until 2008, Newfield drilled more than 150 vertical Granite Wash wells in the Britt Ranch and Briscoe fields in Wheeler County, Tx. Since 2008, all of the wells Newfield has drilled in the Granite Wash have been horizontal.

Early in the drilling of the vertical wells, frac tanks or pits were used at each well site for completion operations. It soon became apparent that having central water supply pits was more efficient and economical. With the required volumes of water growing and the cost of potassium chloride (KCl) increasing significantly, it made economic sense to begin recycling flow-back water. As the company transitioned from drilling and completing vertical wells to horizontal wells in this area, water usage went from about 80,000 to more than 250,000 barrels per completion.

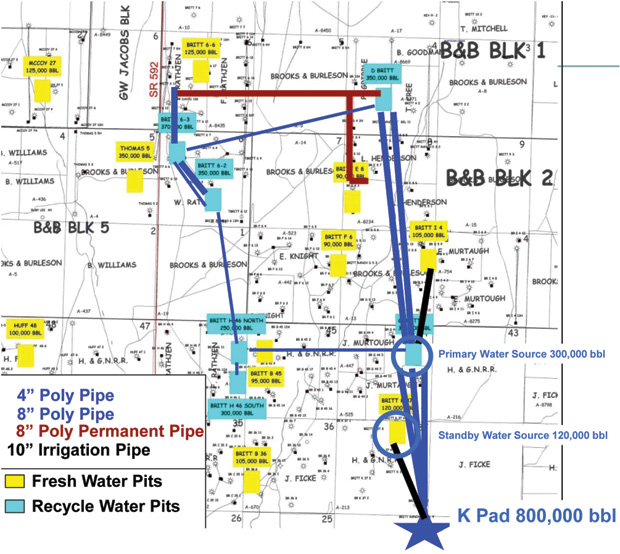

Since most of the water used for completions in the Granite Wash fields is recycled, Newfield uses its own high-density polyethylene (HDPE) pipe to transport water to and from its storage pits (Figure 3). Newfield owns four miles of 12-inch poly, 38 miles of 8-inch poly pipe, and 10 miles of 4-inch poly to move water from pits to the wells being stimulated, from one pit to another, and from the wells back to the recycle pits. Generally, two or three lines are used to pump water from the frac pits to the well being completed.

In these fields, both fresh and recycled water are transported through either 8- or 12-inch HDPE pipe. Once the completion is finished and the well begins to flow back, one poly line is left in place to pump flow-back water to the recycle pits. The company also owns six water transfer pumps to move water from the flow-back or production tanks to the recycle pits.

The water being produced back to the recycle pits is relatively clean, containing approximately the same total dissolved solids as the KCl water that was used initially during the completion operations (15,000-20,000 milligrams per liter). Any solids produced with the water drop out in the flow-back pits. By reusing water, Newfield has saved a significant amount of money and millions of barrels of freshwater during the past five years. Any hydrocarbons not caught in the production equipment (less than 100 mg/l) are skimmed from the pits as necessary and recycled through Newfield’s disposal facilities.

Newfield recycles nearly 100 percent of the water recovered during the flow-back operations (Figure 4). The recycle pits in this area are permitted only for fresh or flow-back water, so once the entire load is recovered, the produced water must be trucked or piped to a saltwater disposal well. In the Britt Ranch area, the company has seven recycle pits with a total capacity of 2.4 million barrels and 10 freshwater pits with a total capacity of 1.3 million barrels. In the Briscoe area, there are two recycle pits with a total capacity of 900,000 barrels. Because of the soil conditions and to protect the environment, all the pits are equipped with geomembrane liners.

The Texas Railroad Commission permits each of the recycle pits. The pits are inspected before they are put in service and then maintained per the permit requirements. Some of the pits have been in use for more than five years without a leak or failure. Depending on the recycle pit permit, some type of monitoring must be done on a routine basis. Once a project has been completed, the pit is closed or maintained in accordance with RRC rules.

Improved Production, Recovery

Newfield Exploration has a long history of drilling vertical wells in the Granite Wash with many operational lessons learned. Since the Granite Wash has multiple productive horizons, the focus was on drilling vertical wells and completing most of the zones using multiple frac stages. Using this approach, the best vertical well in the area had an initial daily production rate of 9.2 million cubic feet of gas and 48 barrels of oil with an initial decline rate in excess of 90 percent when completing eight of the zones. An average vertical well initially produced at a rate of approximately 5 MMcf/d with eight zones completed.

Newfield’s first horizontal well was drilled and completed in an upper member of the Granite Wash during the fall of 2008. That well initially produced at a daily rate of 25 MMcf of gas and 1,500 barrels of oil, and produced 2 billion cubic feet of gas and 100,000 barrels of oil in its first four months. Since that time, 11 zones have been tested in the Granite Wash with horizontal completions. The horizontal wells had an average initial production rate of 17 MMcf/d, with much lower decline rates than the vertical wells. As evidenced in these numbers, horizontal wells have substantially improved both the initial productivities and the recoverable reserves from the Granite Wash.

Along with the improved production and recovery of horizontal wells, however, has come the demand for much more water. The average vertical well was completed using 80,000-100,000 barrels of water. The average horizontal well uses 250,000 barrels of water, or 25,000 barrels per frac stage. Experiments have been conducted using different perforating schemes, water volumes (from 5,000 to 55,000 barrels per stage) and pumping rates (from 40 to 100+ barrels a minute).

Since some of the zones are up to 600 feet thick, attempts have been made to see whether the zones could be drilled with only one lateral and achieve sufficient frac height to recover the reserves efficiently. Based on the fracture mapping, we have not been able to achieve the desired frac height (400 feet). These attempts to intentionally increase the frac height prove that attaining more than 250 feet of height growth is very difficult in most cases. This also shows the implausibility of fracturing into a freshwater zone more than 10,000 feet above the Granite Wash.

Because of the large amount of water required to complete some of the wells in the Britt Ranch Field, the pits have been “daisy chained” together using poly pipe so that water can be moved from pit to pit. Taking this approach, two wells were completed on the same pad using more than 800,000 barrels of water, with the fracs pumped at a rate in excess of 100 bbl/minute and water moved up to nine miles (Figure 5).

Newfield’s approach to water management in the Granite Wash is being used as a model for our new projects in the Cana Woodford, the Eagle Ford in South Texas, the Wasatch in eastern Utah, and the Bakken/Three Forks in North Dakota. The success of Newfield’s water management program has been recognized by other operators. Representatives from other companies have toured Newfield’s water recycling facilities to learn about our efforts and improve their own water management practices.

Woodford Shale

Newfield’s Woodford Shale operations are conducted over a 900-square-mile area in the Arkoma Basin. Like the Granite Wash play, the Woodford Shale was developed initially with vertical wells. The best production was 1,600 Mcf/d, and the average well’s initial daily production ranged between 300 Mcf and 400 Mcf. Drilling and completing horizontal Woodford wells began in the spring of 2005. During the past eight years, the lateral lengths increased from 2,500 to more than 10,000 feet with corresponding increases in initial production rates. The average initial producing rate for Newfield’s Woodford wells was 7.0 MMcf/d. At this time, however, Newfield has suspended drilling in the play as a result of low natural gas prices.

Fracturing volumes on the vertical wells were generally less than 10,000 barrels and could be done from frac tanks or a small freshwater pond. To achieve higher producing rates from the Woodford Shale horizontal wells, much larger fracture stimulations with volumes increasing up to 300,000 barrels a well were required. Some of Newfield’s four-well pads have used as much as 1.2 million barrels of water during completion operations.

As the horizontal play developed, Newfield built more than 60 freshwater ponds to collect rainwater (Figure 6). The ponds ranged in size from 50,000 to 750,000+ barrels, with a total capacity of more than 8 million barrels. Freshwater was transferred from a pond to a well site through 10-inch aluminum irrigation pipe. In cases where there was not enough freshwater in one pond, multiple ponds were connected using irrigation pipe so water could move from pond to pond. Freshwater has been moved up to 2.5 miles during frac operations.

Newfield uses third-party technology to clean its flow-back water in the Arkoma Basin for use as a potassium chloride substitute. The technology removes hydrocarbons, residual chemicals and heavy metals in the flow-back water. This process also kills any bacteria in the water, reduces the surface tension of the water, and reduces sulfate and carbonate scaling tendencies. By using recycled water, we have saved a considerable amount of money each year in reduced KCl usage. Recycled water was trucked from Newfield’s water treatment facility to the well site where it was stored in frac tanks. Freshwater then was mixed with the recycled water through the frac blender to make an equivalent of 1 percent KCl water.

Once the completion was finished and the well was flowing back, the produced water was trucked to a saltwater disposal facility. The water recycling equipment is located at one of Newfield’s saltwater disposal wells and uses the water from the saltwater disposal facility as its source. After the water is processed, it is stored in frac tanks until needed for a completion.

At the time Newfield suspended its drilling in the Arkoma Basin, we were searching for locations to build recycle pits and investigating the feasibility of using higher-chloride water as a frac fluid, which would allow more of the produced water to be recycled.

Cana Woodford

For the past two years, Newfield has been in exploring an oil-rich area of the Cana Woodford Shale covering 10,000 square miles in Central Oklahoma. We have drilled more than 35 wells in the Cana Woodford play, with wells yielding high volumes of oil and natural gas liquids. Only freshwater is being used for our frac fluids (Figure 7). We have been able to cut our freshwater usage by two-thirds and improve well performance by changing from slick water to cross-linked gel fracs.

With the company’s drilling plans and the drought in Oklahoma, it is apparent that another source of water must be developed. As we move from the exploration phase of our drilling program into the development phase, water demand will increase significantly. Newfield is working toward recycling frac water in areas where our infrastructure has grown to a point that it makes economic sense. When evaluating the decision to recycle water, we compare the cost of treating produced water to the cost of acquiring and disposing of freshwater. Reusing the cross-linked gel water presents greater challenges than reusing slick water. Newfield and its vendors are further exploring frac fluid chemistry and water cleanup technology. We are acquiring permits that will allow us to store large volumes of produced and recycled water.

Newfield has recycled millions barrels of water and saved considerable money in completion costs in our Britt Ranch operations over the past five years. The Granite Wash operation is a prime example of where recycling frac water is both environmentally responsible and economically feasible. This is a “win-win” for the landowners, the community and the company. We are working jointly with our vendors so that this recycling model can be used in other areas where Newfield operates.

A core value at Newfield is safety and environmental protection. We choose to work with contractors, vendors and suppliers that have similar views in regard to minimizing the impact of operations on the environment. A commitment to the environment is an important factor in operating a socially responsible company. Newfield’s water management programs significantly reduce the environmental impact of drilling and completing wells in unconventional reservoirs, and we are committed to further improving water use efforts as development operations proceed in the company’s oil and gas resource plays.

D. STEVEN TIPTON is a registered professional petroleum engineer at Newfield Exploration Company, and is located in the company’s Tulsa office. One of his primary responsibilities is water management for Newfield Exploration’s completion operations in the Mid-Continent, where all of its drilling and completion work is in shale and tight oil and gas reservoirs. Tipton has more than 45 years of industry experience, primarily in drilling, completion and production operations throughout the United States, Canada, Trinidad and Yemen. He is a director and chairman of the Scholarship Committee for the Mid-Continent Section of the Society of Petroleum Engineers. Tipton holds a B.S. in chemical and petroleum refining engineering from the Colorado School of Mines, and an M.S. in petroleum engineering from the University of Tulsa.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.