Operators Finding Success In Multiple Rockies Basins

By Al Pickett, Special Correspondent

While the Niobrara/Codell play in the Denver-Julesburg Basin is the headliner among Rocky Mountain basins today–and rightfully so–a number of operators are making big multiphase production news with horizontal wells in the Powder River Basin and vertical wells in the Green River Basin.

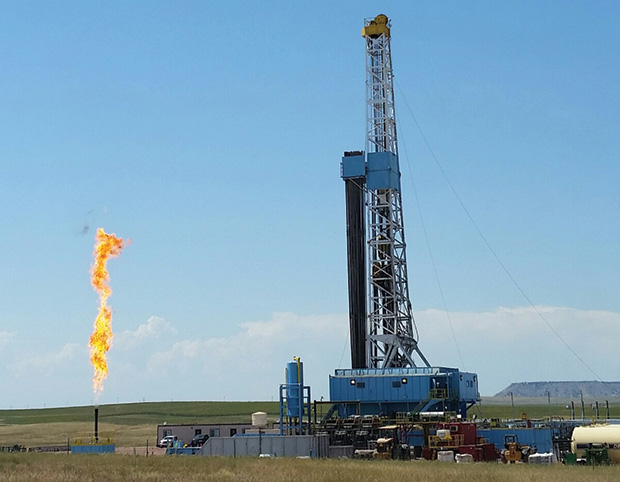

A perfect illustration is a pair of record-producing Powder River horizontals in northeastern Wyoming drilled by Denver-based Anschutz Exploration Corporation.

Anschutz’s initial Turner formation wells–the Theo Fed 3571-17-5-1FH and the Remi State 3671-16-21-9FH–tested at rates exceeding 3,100 barrels of oil equivalent a day. Anschutz reports the Theo Fed initially flowed at a peak rate of 3,193 boe/d (87 percent oil) from an effective stimulated lateral length of 6,872 feet, while the Remi State flowed at a peak rate of 3,123 boe/d (90 percent oil) from an effective lateral length of 8,072 feet.

“We have been quietly building a position in the Powder River Basin over the past five years,” comments Anschutz President Joseph DeDominic. “There aren’t a lot of Turner wells in the area where we drilled the Theo and Remi horizontals.”

The two wells are located five and 11 miles north, respectively, of Chesapeake Energy’s Sundquist 9-34-71 USA A TR 13, which flowed at a reported peak rate of 2,565 boe/d (82 percent oil), also from the Turner formation.

Both Anschutz wells have continued to produce at high rates, according to DeDominic.

The Theo Fed, which was turned to sales on Dec. 9, generated peak 30-day production of 2,187 boe/d, which is equivalent to 318 boe/d per 1,000 feet of stimulated lateral. That represents the top IP30 Turner horizontal well performance in the Powder River Basin, according to DeDominic, who notes the Theo Fed had a peak IP60 rate of 1,862 boe/d and a peak IP90 of 1,721 boe/d. The Theo Fed produced 154,859 boe during its initial 90 days on line.

Meanwhile, the Remi State, which was turned to sales on Feb. 18, generated a peak IP30 of 2,141 boe/d, or 265 boe/d per 1,000 feet of stimulated lateral. It produced 64,215 boe in its initial 30 days, DeDominic goes on.

“Both wells continue to produce more than 1,000 barrels a day,” he lauds.

Finding The Formula

DeDominic says there are a number of reasons for the record wells. “We feel long laterals are an important piece of these wells’ economic success,” he reveals, noting that Anschutz plans to extend future laterals to 10,000 feet.

He also lists the ability to stay in the target zone and an enhanced completion design that includes more perforations and tighter spacing as important contributing factors. However, the company is using smaller proppant loads than what has become common practice in horizontal well construction.

Anschutz Exploration Corp.’s record Powder River horizontals, the Theo Fed 3571-17-5-1FH and the Remi State 3671-16-21-9FH, flowed at peak rates of 3,193 barrels of oil equivalent a day and 3,123 boe/d, respectively, from the Turner formation in northeastern Wyoming. The two wells, which were put into production in December and February, still were making more than 1,000 bbl/d in June.

“These wells are 10,500 feet true vertical depth with as much as 22,500 feet measured depth,” DeDominic remarks. “There is a lot of reservoir pressure. These are good, tight sandstone rocks, so it is our belief that you do not need to hammer them that hard. You just have to hit them with the right design. These are light well completions by industry standards, and we are all still learning.”

He says Anschutz pumped 1,050 pounds of proppant per linear foot in the Theo Fed and 860 pounds in the Remi State.

DeDominic points out that Anschutz has tightened its frac stages from 250-280 feet to 200-215 feet.

“How many clusters per stage is the right number?” he posits. “We are still working on that. We want to get the proppant effectively into all the perforations, impacting as much rock as possible. We are pushing our team for more clusters per stage. Right now, we have seven-eight clusters per stage, but that may be 10-12 in the near future.”

Anschutz has six Turner formation wells awaiting completion and plans to drill six more this year. DeDominic says Anschutz is drilling four wells per 1,280-acre unit.

“It is our philosophy that if you don’t drill and complete those four wells at once, and then go back at a later date, the wells aren’t nearly as good,” he contends. “Given the rock and the pressure, we believe you need to drill all four wells at once to drain the reservoir effectively. If you don’t drill the right number of wells, there will be a lot of oil left down there.”

He says Anschutz is drilling two wells per pad, but is drilling two pads in conjunction with each other.

In addition to the Turner formation, DeDominic says the Powder River Basin has other zones, including the Niobrara and the Mowry. “There is a lot of room for future growth,” he allows.

Anschutz has 400,000 net acres in the Powder River Basin and is operating 26 wells. It is running one rig.

Low Risk

The giant Wattenberg Field in the DJ Basin is the most active play in the Rockies, and one of the most misunderstood reasons for that, according to Bart Brookman, is the low risk factor.

“The Wattenberg Field has the highest return, lowest risk drilling in the country,” maintains Brookman, who is president and chief executive officer of PDC Energy.

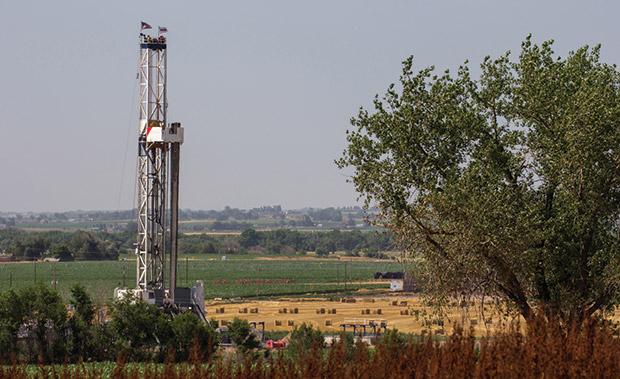

PDC Energy is operating three drilling rigs and one full-time frac crew in the Denver-Julesburg Basin’s Wattenberg Field, where it expects to drill 135-150 wells this year. According to President and Chief Executive Officer Bart Brookman, PDC is averaging 10 days spud-to-spud on its two-mile laterals, which cost $4.5 million to drill and complete.

As an example of the extremely efficient mode companies are employing in the Wattenberg Field, he says PDC Energy is operating three rigs and one full-time frac crew in the play, and will spud 135-150 wells this year. By comparison, the company has three rigs in West Texas’ Delaware Basin, but those three rigs will drill only 25-30 wells this year because of the more challenging drilling environment.

“We are averaging less than 10 days spud-to-spud on our two-mile laterals,” Brookman offers. “That shows the efficiency of the Wattenberg.”

PDC Energy has 100,000 net acres in what Brookman describes as the core Wattenberg, which contains enhanced rock properties, and where there has been extensive vertical development. These enhanced geologic properties lend themselves to consistency in the horizontal program, he says.

“Virtually all of our acreage is held by production, too,” Brookman continues, “so that gives us a lot of operational flexibility.”

The company spudded 35 wells and turned 29 gross operated wells on line in the Wattenberg in the first quarter. Those wells averaged 42 percent oil, 37 percent natural gas and 21 percent natural gas liquids, according to Brookman. He says the wells are targeting primarily the Niobrara formation with the Codell as a secondary target. PDC is drilling an average of 20 wells a section.

PDC Energy drilled its first two-mile lateral two years ago. Today, Bookman reports, the company is focusing almost entirely on 1.5- and 2.0-mile laterals. It has been able to do that because of a strategic effort to consolidate its leasehold, he says.

“Three or four years ago, our acreage was scattered,” he reveals. “Through swaps and acquisitions, we were able to put together very large contiguous blocks. That gives us more opportunities to drill 1.5- and 2.0-mile laterals, which helps with capital efficiency.”

PDC calls its three contiguous blocks the Prairie, Kersey and Plains areas, all of which are located in the inner or middle core of the Wattenberg. Depending on where it is drilling, the oil mix varies from 30 percent to 75 percent, according to Brookman.

He adds that PDC Energy has been able to maintain its cost structure of $2.5 million for wells with 1.0-mile laterals, $3.5 million for 1.5-mile laterals and $4.5 million for 2.0-mile laterals.

Brookman says the company will drill as many lateral feet this year with three rigs as would have required seven or eight rigs five years ago, exemplifying the drilling and completion efficiency that it has attained.

“We continue to make small changes,” he assures, listing technical design, improved bits and downhole assemblies, better steering, and rig automation as reasons for the improved efficiency. “It is technology. That is what our industry is great at. These improvements are technology driven.”

Midstream Expansion

Rapid development of the DJ Basin has met some midstream constraints, but Brookman says he believes “substantial relief on line pressure” is near.

DCP Midstream’s Mewbourn 3 cryogenic natural gas processing plant will come on line in August near Greeley, Co. That will be the company’s 10th plant in the DJ Basin, and will add 200 million cubic feet a day of gathering and processing capacity, increasing DCP’s total capacity in the basin to 1.050 billion cubic feet a day.

DCP Midstream’s Mewbourn 3 cryogenic natural gas processing plant, shown here, will come on line in August near Greeley, Co. It is the company’s 10th Denver-Julesburg Basin plant and will add 200 million cubic feet a day of gathering and processing capacity. President, Chief Executive Officer and Chairman Wouter van Kempen says DCP anticipates adding 500 MMcf/d of processing capacity in the basin over the next 12 months and 1.5 billion cubic feet a day over the next several years.

“That is the first step in providing substantial high-line pressure relief,” Brookman states. “This enables PDC to unbundle production.”

The Mewbourn 3 project in Weld County, Co., includes the next phase of DCP’s Grand Parkway low-pressure gathering and associated compression assets, which also are expected to be completed by the end of 2018. Total capital investment for the plant and associated gathering is expected to be $395 million.

Wouter van Kempen, president, chief executive officer and chairman of DCP Midstream LP, points out, “We will add 1.5 Bcf/d of capacity over the next number of years. We will add 500 MMcf/d of capacity over the next 12 months.”

The O’Connor 2 plant expansion, which will add another 300 MMcf/d on top of the Mewbourn 3 plant’s 200 MMcf/d, is expected to become operational in the second quarter of 2019. In addition to its 200 MMcf/d of processing capacity, the O’Connor 2 expansion will add 100 MMcf/d of bypassed capacity.

“Bypassed gas is untreated gas that we will route around the plant,” van Kempen explains. “It will be mixed with processed gas at the plant’s tailgate to make it meet pipeline specifications. We aren’t taking the ethane and butane out, but it creates additional capacity.”

DCP also has an option on land and has filed permits to build a 12th gas processing plant in the DJ Basin southeast of Greeley.

van Kempen says DCP Midstream is “providing an all-encompassing, cradle-to-grave solution” that alleviates bottlenecks by providing take-away capacity for NGLs, residue gas and crude oil, as well as gas gathering and processing.

For example, he says the company is adding up to 220,000 bbl/d of NGL take-away in the DJ Basin through its Southern Hills extension of the White Cliffs Pipeline, and its Front Range and Texas Express expansions. Both expansions are expected to go into service in the second quarter of 2019.

“Our goal is to make sure we get ahead of our customers in providing solutions,” van Kempen states. “The DJ Basin has been constrained. Producers can move faster than we can. Our goal is to provide all-encompassing, fully integrated solutions to not only gather and process gas, but to also provide take-away capacity for residue gas and NGLs.”

Longer Laterals

Thanks to 20 acquisitions over the last five years, Denver-based Extraction Oil & Gas is now the third largest leaseholder in Colorado with 325,000 acres. Senior Vice President of Operations Eric Jacobsen says Extraction has 175,000 acres in the core Wattenberg with its remaining acreage in the North Colorado Extension.

Denver-based Extraction Oil & Gas–the third largest leaseholder in Colorado–is averaging nearly two miles per lateral developing 22-24 wells a section in the Wattenberg Field, targeting the Niobrara A, B and C benches as well as the Codell Sandstone. In 2017 and early 2018, the company drilled, fractured and turned on line 22 2.5-mile wells on the Triple Creek pad in only 10 months.

Most of the company’s focus is on the Wattenberg, however, where Extraction has three rigs running and plans to spud 190 wells this year, according to Jacobsen.

“We are nearly one-to-one with drilling and frac crews,” he mentions. “We maintain two to three frac crews.”

Part of Extraction’s success in the Wattenberg is attributable to longer laterals. “We average nearly two miles per lateral now,” Jacobsen comments. “In fact, two miles and beyond represent 90 percent of our inventory. We understand the reservoir and are developing 22-24 wells per section.”

Extraction believes in full development, he says, meaning it drills all 22-24 wells in a section at one time for optimum drainage before moving on. “We don’t anticipate going back to a section,” Jacobsen remarks.

He points out that in 2017 and early 2018, Extraction drilled, fractured and turned on line 22 2.5-mile wells on a single pad: the Triple Creek pad, in only 10 months. “That is an example of how efficient we have become,” he boasts.

The majority of its acreage is held by production. Jacobsen says Extraction is targeting the Niobrara A, B and C benches as well as the Codell Sandstone in each section.

“We have fewer vertical penetrations in our area,” he reflects. “Because of that, our acreage is the least depleted from vertical wells. That makes for the best Codell, which is the differential. The last 120 wells we drilled have 1 million-plus boe estimated ultimate recoveries.”

Extraction’s Wattenberg wells average 65 percent liquids (50 percent oil and 15 percent NGLs) and 35 percent gas.

“Our cycle time is remarkable,” Jacobsen continues. “Our record for a one-mile spud-to-rig-release is 1.8 days. For a two-mile lateral, it is 3.8 days. Our cycle times in the DJ Basin are the lowest among any major plays in the country, and we believe among the lowest in the Wattenberg.”

Right-Sized Fractures

Drilling longer laterals, however, is only part of Extraction’s successful equation. “One size doesn’t fit all,” Jacobsen cautions. “We use the right size frac for each area. We use deep surface understanding and a lot of engineering to determine what delivers the highest production per section. We are using a more enhanced fracture with increases in sand and fluid, and we are more aggressive on our flowback.

“We also have become more efficient at drilling out frac plugs to give us good, clean holes,” he adds. “It depends on the gas-to-oil ratio and the porosity of the rock, too. Those are all things we take into account.”

He says Extraction uses a mix of artificial lift, ranging from gas lift to compression, plunger lift and rod pumps, depending on the area.

Jacobsen says he believes the Wattenberg offers the lowest cost structure of any horizontal play with a per-well cost for a two-mile lateral of about $5 million.

He acknowledges that the DJ Basin has faced bottlenecks, especially in gas processing. “But Extraction is uniquely positioned with our acreage to take advantage of DCP Midstream’s Mewbourn 3 and O’Connor 2 plants, as well as Western Gas and another third-party processor,” Jacobsen observes.

“From August through April 2019, all new wells can go onto the DCP system, but we can pivot between gas processors,” he continues. “We have been able to grow our oil production consistently while working around the gas processing constraints. The line pressure has impacted us, but we have been able to maintain our targets.”

Jacobsen says he believes the 1.2 Bcf of gas processing capability coming on line among DCP Midstream, Anadarko and Discovery in the next year will “unlock the basin.”

Extraction’s acreage is concentrated around Greeley and down the west I-25 corridor to Boulder and Broomfield into Adams and Arapahoe counties, Co. That includes its South Hawkeye development south of the Denver International Airport.

Focus On The DJ

Thanks in part to its Land Grant acquisition of more than 7 million acres from Union Pacific Resources in 2000, Anadarko Petroleum Corporation is one of the largest producers in the Rockies, with acreage stretching from the DJ Basin in Colorado to the Green River and Powder River basins in Wyoming as well as the Uinta Basin in Utah.

But Anadarko’s primary focus in the Rockies is on the DJ Basin, according to Carrie Horton, vice president of DJ Basin development.

“We have simplified our corporate portfolio,” she states. “Most of our Rockies investment is in the DJ Basin.”

Anadarko Petroleum Corporation holds 400,000 net acres in the Denver-Julesburg Basin with 4,000 remaining drilling locations. The company averages eight wells per pad in the basin with a type curve of 690,000 barrels of oil equivalent a well. It will average running five drilling rigs this year along with three completion crews.

Anadarko holds approximately 400,000 net acres with 4,000 remaining drilling locations in the DJ Basin, and Horton says the company has plans to drill around 300 wells each year there well into the next decade.

“We definitely are in the manufacturing mode in terms of efficiency,” she declares. “We know what wells we plan to drill for the next three years. We have improved costs by 55 percent, increased the number of wells per pad by 100 percent, and reduced our cycle time by 50 percent. We also benefit from the experience gained by drilling this many wells. We try to keep steady, qualified completion crews.”

Horton, who says Anadarko now averages eight wells per pad, notes its type curve is 690,000 boe per well. She says the Niobrara offers multiple benches, so the company’s pads are always a mix of the various Niobrara benches as well as the Codell formation.

Anadarko has 3,800 vertical wells and 1,500 horizontal wells producing in the DJ Basin. It averaged more than 260,000 boe/d in the first quarter, an 8 percent increase over first quarter 2017, Horton reports. The company estimates it has more than 2 billion boe of net resources on its acreage. She adds that Anadarko will average five drilling rigs this year along with three completion crews that utilize equipment with noise-reduction technology.

Anadarko also operates its Integrated Operations Center in Platteville, Co., which is staffed 24 hours a day, seven days a week, 365 days a year. It provides real-time remote-monitoring capabilities for more than 8,000 horizontal and vertical wells and 3,700 tank facilities.

Horton says Anadarko and its sponsored midstream master limited partnership, Western Gas Partners LP, have midstream infrastructure as well, providing gas gathering and processing, and oil stabilization.

One reason for Anadarko’s success, according to Horton, is using data analytics for finding the right recipe for each formation and each area of the basin. She says Anadarko has successfully tested extended reach laterals with a record of 13,000 feet. It still is tweaking higher fluid injections and optimizing stage spacing, but Horton notes that the correct recipe varies from the Niobrara to the Codell. It is not cookie cutter.

“It is fascinating,” she marvels. “The recipe is different on each well. It takes a lot of work on technology and looking at data to find the right recipe. We use big data analytics as we study surface data and mix them with completion design.”

Because of its Land Grant advantage, Horton says, Anadarko typically owns every other section in its two-section drilling units. “We receive a 40 percent uplift because of that, based on $50 West Texas Intermediate and $3 Henry Hub prices,” she reveals. “Because we own the mineral rights on much of our acreage, our break-even price is $20 a barrel. We are very resilient to service cost increases, and our asset generates significant free cash flow. The DJ Basin is a powerful piece of our portfolio that can fund other growth areas and contribute to discretionary cash flow.”

Williston Basin

C. Mark Pearson acknowledges that there has been a slowdown from the earlier breakneck pace of drilling in the Bakken/Three Forks play in North Dakota as some companies have “exited for the big rush to the Permian Basin.”

Liberty Resources’ Leon central production facility has been operating since February 2015, handling production from 17 wells. It provides four stages of gas capture and three-phase metering for each well. Liberty has been working in the Bakken Shale since 2009 and was the first to utilize high-intensity slickwater fractures. It holds 100,000 net acres in the North Nesson Anticline area of the Williston Basin.

“But we have been drilling continuously since 2015,” says Pearson, president and chief executive officer of Liberty Resources II LLC.

The Liberty team has been working the Bakken since 2009, according to Pearson, first in the Central Basin, which is considered the core of the Bakken. It sold its assets in mid-2013 for $680 million and then re-entered the basin in 2014 as Liberty Resources II.

Today, the company has 100,000 net acres in the North Nesson Anticline area of the Williston Basin, and Pearson says Liberty is finding great success, even though the North Nesson Anticline is not considered to be in the Bakken core.

“We are on our Generation 5 completion design,” Pearson remarks. “We are able to squeeze more out of the rocks. These wells are economic at $50 a barrel and very economic at $60 a barrel.”

He claims Liberty has been among the best in the basin in well performance, and was the first to use high-intensity slickwater fracs in 2009.

Improved economics as well as improved completion design and drilling efficiency have contributed to Liberty’s success in the North Nesson Anticline, Pearson says, where it is operating one rig at the moment, but plans to add a second later this year.

Because these wells produce a high water cut (as much as 60 percent), Pearson says Liberty uses jet pumps for the first couple years. Liberty’s wells have EURs of 700,000-850,000 boe (80 percent oil) with a gas-to-oil ratio of 1,500-2,000.

Pearson says his company is drilling three-mile laterals. “The industry has drilled 150 laterals longer than 2.5 miles in the Bakken, mostly to reach around surface issues such as drilling under Lake Sakakawea,” he notes. “But we are doing it for pure economics. Drilling a three-mile lateral gives you 40-45 percent more product at only 20 percent more cost.”

Liberty plans to drill seven more wells this year, four of which will be three-mile laterals. Cost is $8.4 million a well, according to Pearson.

Because of the improvements in technology and completion design, Pearson claims Liberty’s wells in the North Nesson Anticline are better than its wells in the Central Basin core were three or four years ago. “Our rate of return on these wells with $50 oil is higher than it was with $95 oil in 2013,” he emphasizes. “That shows the improvements in efficiency and cost reduction.”

Enhanced Oil Recovery

Liberty Resources has received approval to begin a rich-gas enhanced oil recovery test in July in the Bakken, which Pearson says will be the industry’s first drill-site spacing unit full miscible injectant pilot. He describes it as an “ethane-rich-gas huff-and-puff.” He says waterfloods won’t work in unconventional plays, so the industry needs to move straight to tertiary recovery.

The Bakken-produced gas has favorable miscibility, Pearson points out. The rich gas is an effective solvent for oil recovery and thus works as well as carbon dioxide in an EOR project. Consequently, he says, Liberty is taking the produced gas from its own wells and injecting it into six cemented-casing wells on a pad that was drilled three years ago.

“We are excited about the project,” Pearson exclaims. “We will take the 20 percent ethane and 60 percent methane gas and compress it into our producing wells. There will be a one- to two-month injection cycle, so we will need six months to see how we are doing.”

He says projections from reservoir simulations and laboratory studies predict enhanced oil recovery will produce an additional 250,000-500,000 barrels of oil per well.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.