Nanofluid Technology Slows Production Declines In Wolfcamp Restimulations

By Panagiotis Dalamarinis and Amr Radwan

BERWYN, PA.–The post-flowback behavior of horizontal wells completed with multistage fracturing typically includes steep hydrocarbon production declines that often are accompanied by increasing water cuts. In fact, well production in many unconventional basins declines by more than 40% on average during the first six months of production. While reservoir fluid properties and production characteristics play an important role, this behavior is partly the result of both near- and far-field fracture conductivity damage.

Refracturing with acid or proppant has proven an effective solution in multiple basins to mitigate these problems by cleaning out fractures and stabilizing oil recovery trends.

In the Delaware Basin in the Wolfcamp play, a successful pilot to improve long-term well performance used acid stimulation aided by a pioneering tailored metal oxide (TMO) nanoparticles-based fluid. In this project, seven wells in two different areas with similar designs, the same geological landing zone (the Wolfcamp A), and located within one mile of one another were selected to be restimulated with different surfactant blends. The wells were collectively producing 4,500 barrels of water on average at a 96% water cut. An acid stimulation treatment of ±2,000 barrels was designed for each well. Regular surfactant was added to the treatment fluid in five wells while two wells implemented the TMO nanofluid.

Water cuts, gas-to-oil ratios (GORs), and hydrocarbon decline rates were monitored daily to observe any significant differences between the well production behaviors. The surfactant-injected wells demonstrated an average production decline of 40% over the first six months. However. the TMO nanofluid-injected wells showed a production decline of 5% in the first month followed by a production improvement of 10% in the second month and an overall production decline of less than 10% after six months. This type of behavior is consistent with previous field experiences with the nanofluid where production improvements had been sustained over time.

Unique Characteristics

The TMO nanofluid provides a unique long-term wettability alteration, reducing interfacial tension (IFT) and allowing chemicals to be retained in the fracture/reservoir phase. It also functions to remove near-wellbore organic formation damage through the structural disjoining mechanism. The unique characteristics of this new technology in acid restimulation treatments can help restore well/reservoir conductivity and remove near-wellbore formation damage, resulting in better long-term performance characteristics with improved production decline rates.

The properties of surfactants can reduce IFT between the aqueous and hydrocarbon phase, decrease the surface tension by foam generation, disperse two or more immiscible liquids by emulsification, and alter the formation’s wettability. All of these features reduce the capillary process and enhance spontaneous imbibition by promoting more favorable conditions to increase oil recovery. Normal surfactants suffer from different weaknesses in terms of solubility, thermal stability, pH, salinity, adsorption and other reservoir parameters that lead to poor oil displacement performance.

The purpose of replacing normal surfactants with the TMO nanofluid is creating bonds between the fracture phase and rock matrix, subsequently overcoming problems associated with normal surfactants and providing long-term production maintenance. TMO nanofluids are made of proprietary blends of metal oxide nanoparticles and other additives to improve the stability and compatibility under harsh reservoir conditions. Several field application studies have demonstrated the technology’s ability to enhance well performance.

TMO nanofluids are nontoxic, non-hazardous water-based fluids containing one or multiple types of metal-oxide nanoparticles with stabilizing chemistry. They are engineered to be effective under a range of lithologies, salinities, crude oils, temperatures and pH changes. The small size of the nanoparticles provides the maximum surface area for interaction with fluids and rock materials to provide long-term wettability alteration.

The fluid system works through a structural disjoining (“uplift”) pressure mechanism by which the nanoparticles form a wedge beneath organic matter and allow it to disconnect from the surface against different crude oil types. TMO nanofluids have been applied as a stand-alone stimulation for producing oil wells in several basins. These results show a trend of alleviating decline rates in treated wells, which is believed to be linked to the long-term wettability alteration mechanism. The effectiveness of the treatment improves when the nanofluid can be tailored to specific crude oils and rock mineralogy.

Wolfcamp A Wells

The Delaware Basin project included one group of three wells in Reeves County, Tx., and a second group of four wells in Culberson County, Tx. Each Wolfcamp A well group had different reservoir and production characteristics, and all were on electrical submersible pumps. Water and oil samples were collected and analyzed for each well. TMO nanofluids were used in one well in each well group (wells A and G) instead of normal surfactants.

After initial flowback of approximately two weeks, the ESPs were operated with a schedule that allowed similar drawdowns for all wells of ~5 psi a day (based on pump intake pressure data). This approach was selected to provide better relevance to well production performance and evaluation, but also to manage the reservoir drawdown and offset well interference.

A propitiatory TMO nanofluid was designed based on information provided by the operator to maximize performance. A series of laboratory tests were conducted at a temperature of 180 degrees Fahrenheit at different dosages. The nanofluid was mixed with wellhead waters from the two subject wells to investigate brine compatibility, emulsion and acid stability. Interfacial tension testing and contact angle measurements also were completed.

The operator also provided crude oil samples from the two wells to evaluate emulsion stability with the TMO nanofluid. For both the A and G wells, two samples were prepared using 50/50 volume ratios of water/crude oil and nanofluid/crude oil and evaluated for emulsion stability at a temperature of 180 degrees. No emulsion issues were observed from all four samples, and the nanofluid broke emulsions completely. Subsequently, a TMO nanofluid solution was added to 20% hydrochloric acid to observe acid stability testing over 24 hours at 180 degrees. The test was successful, with no compatibility issues, and the solution was stable.

IFT was measured between the nanofluid and crude oil to understand the nanofluids’ behavior in modifying the wettability of the formation rock. The contact angle was measured between a Wolfcamp A rock sample, crude oil and the nanofluids. The TMO solution showed excellent performance by modifying the wettability of the rock and replacing the carboxylic particles and creating a wedge film to displace the oil droplets out of the rock surface.

Overall, 5 gallons per 1,000 gallons of TMO nanofluid was recommended for the pilot test to achieve better wetting conditions, remove organic scale damage and provide long-term wettability alteration.

Production Results

The three wells in Reeves County have water cuts of ~95% and GORs of 9,000 Mcf per barrel of oil. All three are landed in the Wolfcamp A and completed with similar stimulation programs of ~2,000 pounds of proppant and 55 barrels of fluid per foot. The acid restimulation treatments with diverter balls and chlorine dioxide pumped TMO nanofluid in one well (Well A) and normal surfactants in the other two wells (B and C). The treatment volumes of the acid jobs, as well as the surfactant volumes, were similar on a per lateral foot basis. The A and B wells are in the same pad and offset each other, while Well C’s toe is at the heel of Well A.

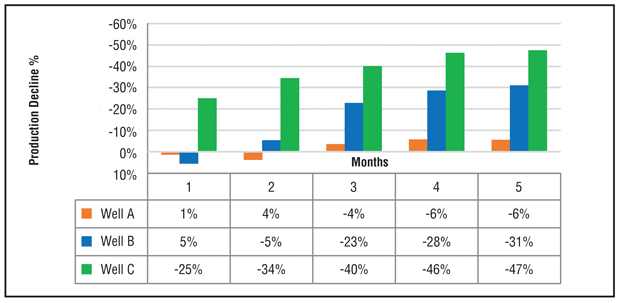

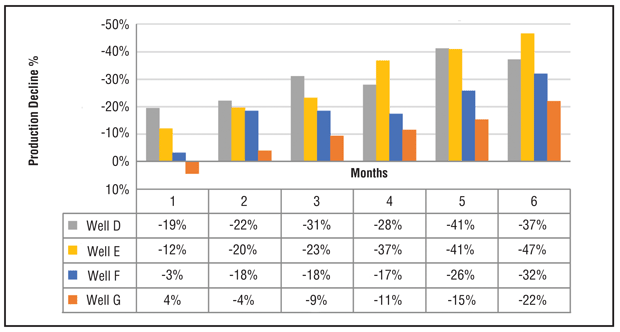

After five months of production, the B and C wells treated with surfactant demonstrated average barrels of oil equivalent a day production declines of 31% and 47%, respectively (Figure 1). Well A with TMO nanofluid had a boe/d decline of only ~6% over the same production period. Similar behavior was demonstrated in the oil and gas for all three wells (Table 1).

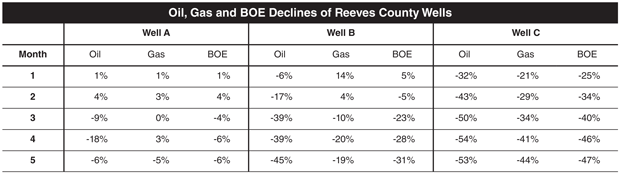

After 12 months, a workover had to be conducted on Well B to replace a failed ESP. With production performance data using normal surfactant available for the well, the operator decided to use the TMO nanofluid during the acid restimulation of the well to evaluate its effect on production. Initial flowback data showed oil, gas and boe production ~20% higher than it had been after the first acid restimulation was performed 12 months earlier.

After two months of production following acid restimulation with the TMO nanofluid (not accounting for the initial two weeks of flowback), Well B had a significant improvement in the production decline compared with the first acid restimulation treatment pumped a year before using normal surfactant. In the first two months after the first acid restimulation treatment, Well B had demonstrated an oil production decline of 17%, a 4% increase in gas and a 5% decline in boe. For the same production period following the second restimulation treatment with TMO nanofluid, the well had average production increase 5% for oil, 15% for gas and 11% for boe (Figure 2).

In Culberson County, three of the four wells are located in the same pad (wells, D, E and F) while the fourth (Well G) is in an offset pad 0.6 miles to the east. Wolfcamp A wells in the area have a water cut of ~97%, a GOR of 15,000 Mcf/bbl and significantly higher water rates when compared with wells on the Reeves side of the county line. The PVT characteristics make the Horseshoe Area wells in Culberson County challenging economically. All four wells had similar legacy completion designs of 2,000 pounds of proppant and 55 barrels of fluid per foot. One major difference was that wells D, E and F had net stimulated laterals of ~6,500 feet while Well G had a net stimulated lateral of only 3,500 feet. The volumes of the acid restimulation jobs, as well as surfactant/TMO nanofluid volumes, were kept the same on a per lateral foot basis.

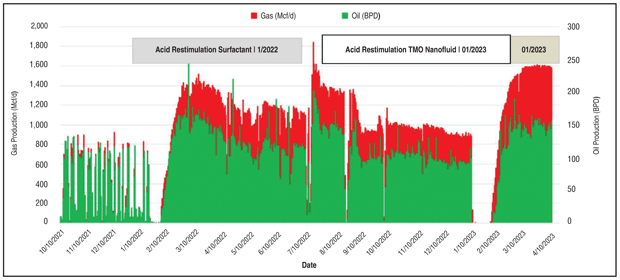

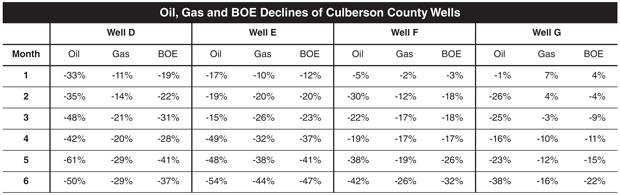

The TMO nanofluid was used in Well G while wells D, E and F were treated with surfactant. Figure 3 shows six-month production data for all four wells. Wells D, E and F demonstrated average boe production declines of 37%, 47% and 32%, respectively. Well G at had a boe decline of 22%. Similar behavior was demonstrated in the oil and gas production, with Well G outperforming the other wells by at least 30% in terms of oil, gas and boe decline (Table 2).

These applications in Wolfcamp A wells with high water cuts and GORs demonstrate the potential for applying TMO nanofluid in acid restimulation treatments to improve overall production behavior and dramatically reduce average production declines.

PANAGIOTIS DALAMARINIS is a subsurface manager at DG Petro Oil & Gas in McKinney, Tx. He previously served as completion and technology commercialization manager at Seismos Inc., petroleum engineer at C&J Energy Services, petroleum engineer at EPT (formerly Michael J. Economides Consultants Inc.), and a researcher at Robert Gordon University. Dalamarinis holds an M.S. in petroleum engineering the Technical University of Crete.

AMR RADWAN is co-founder and chief technology officer of TenEx Technologies. Before starting TenEx, he managed North American technical sales and business development for Sahara Petroleum Services and served as vice president of technology and innovation at Preferred Sands. Earlier in his career, Radwan held engineering roles related to drilling, completion, production and workover operations. He holds a B.S. and an M.S. in petroleum engineering from Cairo University.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.