Digitization Helps Revive Mature Wells

By Colby Wilson, Arin Cline and Paul Marino

With concerns about remaining drilling inventory in many unconventional basins, improving recoveries to extract more barrels of oil and cubic feet of gas from each well has become an area of focus. Co-completed multiwell pads, longer laterals and increasingly advanced hydraulic fracturing treatments point to ways operators are strengthening recovery rates. In fields where the efficacy of enhanced oil recovery has yet to be fully tested, mature vertical wells in many parts of the country offer an enticing opportunity to recover more hydrocarbons at a relatively low cost.

Wells that produce fewer than 15 barrels of oil equivalent a day account for the lion’s share of the onshore U.S. well count at 77%, according to the U.S. Energy Information Administration. Cumulatively, these wells contribute approximately 10% of the country’s overall production. Modest investments that extend their lives can pay steady dividends. And given the sharp decline rate of shale wells, managing the long tail of hundreds of thousands of lower-flowing assets is a crucial skill set for sustaining U.S. energy dominance in the coming decades.

Monterey Production Co. is a natural-gas-weighted startup born from the ashes of Covid-19 demand destruction in 2022. Having grown through two acquisitions, it operates more than 300 legacy vertical wells in Northwest Oklahoma. Monterey’s buy-and-revive business model has enabled it to breathe new life into wells that have been poorly maintained or even shut in, transforming distressed assets into revenue generators by extending production with well-timed maintenance and workovers.

Central to Monterey’s production strategy is a digital backbone that supports all its business functions with actionable data, from daily sales numbers and artificial lift key performance indicators to regulatory reporting and data required to secure reserve-based loans. Rather than operating its business on the traditional energy software it inherited with its first legacy well acquisition, Monterey has adopted modern, cloud-native technology that seamlessly connects the field and back office with a mobile app, production reporting, field ticket management and real-time data.

This article will explore Monterey’s digital strategy and how a centralized backbone of real-time data accelerates business performance, contains costs and empowers every member of the company’s team with the information required to take the next best step.

Real-Time Business Optimization

The professional background of Monterey’s founder and managing partner played an important role in starting the company off on the right digital foot. As a drilling engineer turned entrepreneur and operator, he sees real-time visibility into operational performance and access to data as the baseline for safe and efficient operations, as well as a key enabler of continuous improvement.

On a rig, drillers and company personnel must have a real-time view of bit position and wellbore trajectory, which is made possible through measurement-while-drilling tools. Drillers do not wait until the end of the day or month to make a course correction, but in field operations, many producers do. Business course corrections often occur after the monthly close, when sales and expense trends inform budgets and production targets.

For small independent producers with narrow margins, waiting until the end of the month or even the week to assess cash flow and inbound expenses is particularly harmful. The lagging indicators result in reactive decision-making that erodes the bottom line.

This vertical well in Northwest Oklahoma is one of many operated by Monterey Production Co. The company has built its business around finding efficient ways to improve production from legacy wells, including some that were previously shut in.

Monterey’s pumpers and production engineers witnessed this first hand. In addition to lacking pumper-friendly features, legacy field data capture solutions imposed a data lag gap of days or weeks. This led to a domino effect of delays in the back office, where engineers struggled to piece together wells’ key performance indicators and identify the best steps toward optimization.

While Monterey has relatively low production allocation complexity thanks to its natural gas focus, allocations on its crude oil sales remained difficult and unreliable with legacy technology. A lack of timely data in ready-to-use formats also impeded reserves workflows and applications to lenders. Furthermore, preparing monthly regulatory filings with the Oklahoma Corporation Commission required staff to chase production and emissions data, piece together disparate sources, and manually prepare regulatory reports.

From its beginning, Monterey set out to implement processes and technology that would enable all the company’s team members to optimize business performance in real time and reduce manual tasks and rework, which meant the company could manage more assets with existing resources.

Current Assets

Monterey acquired its first wells in Northwest Oklahoma from a bank that received the assets after the former operator’s bankruptcy. The wells had been shut in following the turmoil of the 2020 pandemic.

Monterey applies a selective buy and revive strategy that considers well health, commodity prices and workover costs. As a result, natural gas wells that do not break even may see new life in the coming years with improving economics. Even Monterey’s stranded Oklahoma assets are likely to benefit from stronger prices associated with new liquefied natural gas export facilities on the Texas and Louisiana Gulf Coast.

Following two acquisitions, Monterey now operates 326 wells producing an average of 8.5 million cubic feet of gas a day, which the operator sells to local markets. Monterey produces between 50 and 60 barrels of crude oil a day from multiple wells, resulting in low flow and partially filled oil storage tanks at the lease. To maintain cash flow, it often calls in split loads to capture revenue from these sales runs.

To maximize margins, Monterey sought to improve its field ticket management and reduce costs by combining split loads into a single sales run. Limited by its legacy energy software’s lack of robust tools to monitor open loads and schedule sales runs, Monterey deployed a modern field data capture solution that connects the field and back office in real time, leveraging modern field mobility technology that makes it easy for pumpers to capture lease assessments and sales runs.

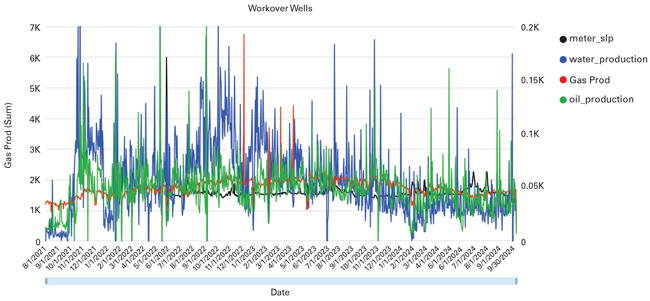

By investing in a cloud-based production and field operations platform, Monterey has given its employees easy access to the information they need to refine its workover program and other production optimization efforts. The company’s team regularly references 22 reports, including a workover report that contains this graph, which tracks gas, oil and water production, as well as meter slippage, from wells that have recently undergone a workover.

The cloud-based solution serves as the system of record for all field operations and production data, featuring powerful tools to manage and enforce master data, such as well names and API numbers. This master data is used throughout the solution to ensure pumpers enter correct values during lease assessment using a mobile app on phones or tablets. Ultimately, such data governance leads to clean and consistent asset lists and reliable information.

Monterey’s field ticket management solution provides clear and current visibility into crude oil volumes stored across 11 tank batteries, enabling the operator to know exactly when to dispatch haulers to combine split loads for sale. This capability improves cash flow by reducing costs and accelerating revenue to the bottom line.

The cloud-based production reporting software provides a comprehensive sales reconciliation module that helps ensure payment accuracy from purchasers by comparing daily volumes to statements and highlighting potential payment errors.

Hitting Production Targets

As part of its vision for data-driven operations, Monterey wanted to gain production visibility on a real-time, intraday basis and generate a wide variety of reports that support production optimization. For example, to minimize downtime and keep revenue flowing without interruption, Monterey’s team carefully monitors wells’ production decline curves and artificial lift systems, watching day-to-day variances in production volumes and key performance indicators for plungers, casing, tubing and other systems. This data then helps determine when to call for a workover rig, replace equipment or perform other production optimization activities.

At a glance, the production dashboard shows daily and historical oil, gas and water volumes alongside field notes, explanations for a well’s inactivity, and sales. Users can drill down with a click to detailed well pages with production graphs, equipment, events and ownership information.

Production volumes and artificial lift data captured by pumpers are instantly available for analysis inside dashboards and an extensive library of prebuilt reports. These include a custom line pressure report that the solution provider has built quickly to support Monterey’s artificial lift tracking and production optimization.

Well Data Clearing House

Monterey’s field mobility and cloud reporting solution creates a digital backbone that begins with validated pumper data entry and flows along interconnected links by department, including engineering, production accounting, well work, logistics and management. Data flows both ways, enabling well data, run tickets, engineering analyses and KPIs to drive cross-disciplinary decisions. This includes sharing the insights and results generated from daily lease assessments with the field staff responsible for capturing the data. When pumpers see the impact of their contributions, their productivity and job satisfaction increases.

By creating a centralized clearing house of high-quality well and production data, Monterey leverages its digital backbone to power additional workflows. For example, regulatory reports that previously burdened staff with manual data wrangling and report building now can be automatically generated from Monterey’s well data clearinghouse using a prebuilt OCC report, simplifying compliance and enabling staff to redirect time into other priorities.

Workflows outside the solution also are supported. With a single click, users can export dashboards, report views and other data into spreadsheets and other applications for further analysis.

The solution integrates with Microsoft Excel to support Monterey’s existing workflow for reservoir engineering and production optimization. Engineers easily can bring production data into spreadsheet workbooks, which, in turn, feed data into Microsoft PowerBI. Data and decline curves extracted from the field mobility and reporting solution also are used to forecast production and justify reserve-based lending with Monterey’s lenders.

Monterey intends to expand its operations by acquiring additional assets in its area of interest. By building a digital backbone that tracks historical asset performance by acquisition, the solution provides an important capability to report on individual acquisitions or roll up assets for a complete view, assisting in return on investment analysis. The company’s efficient well and master data management also accelerates returns by enabling it to onboard assets with speed and efficiency.

Sustaining Operational Excellence

Monterey’s digital strategy for field operations and production management provides a throughline that connects its entire team with data and actionable insights at their fingertips, optimizing business performance throughout the day and setting Monterey up to meet its growth objectives. It has become an integral part of the day across its organization, from the desk of the managing director monitoring KPIs to the hands of pumpers.

Field adoption is where many digital oil field initiatives live or die. The success of Monterey’s choice of pumper apps demonstrates precisely how user-friendly field mobility should be.

The operator’s team uses 22 dashboards and report types on a daily or weekly basis, including ones covering daily production (gross and net), production variance, downtime, plungers and workovers.

Instead of relying solely on monthly reporting and sales reconciliation alone to course correct and adjust business targets, Monterey tracks real-time tank battery levels, enabling it to optimize run tickets, combine split loads of crude oil and maximize daily cash flows. The team minimizes field costs from maintenance and workovers by tracking artificial lift performance daily to understand equipment and production trends, reduce well downtime and right size well work based on field data.

Monterey’s field mobility and production reporting solution enables management to start the day poised, accelerates reserves workflows, automates state regulatory reporting and equips pumpers to advance operational excellence. At the same time, the digital backbone helps the company navigate the complexity of mergers and acquisitions, onboard new wells and track each of its acquisitions separately from one cloud-based dashboard. As Monterey continues to expand, streamlined workflows will empower it to achieve its mission of breathing new life into mature wells with a lean, digitally-enabled team.

Colby Wilson is the managing partner of Monterey Production Co., which he founded after a 10-year career as a drilling engineer. By applying his deep appreciation for data-driven operations and continuous business optimization to Monterey, he has successfully revived production from legacy wells for sustainable returns. Wilson also serves as president of 266 & Co., a full-service earthwork, excavation and grading contractor based in Tulsa. Before starting Monterey, he held foreman and drilling engineer positions at Kaiser Francis, Tecolote Energy and Newfield Exploration.

Arin Cline is a production operations specialist at Monterey Production Co., where she oversees daily reporting for sales, artificial lift systems and workovers. She has more than 15 years of oil and gas experience. Prior to Monterey, Cline held senior operations technician, production system specialist and accounting roles for Midstates Petroleum Co. and Eagle Energy. She began her oil and gas career as a materials analyst at Newfield Exploration.

Paul Marino is the general manager, founder and original creator of PakEnergy’s Pak Production software (formerly ScoutFDC). With more than 20 years of application development, business operations, sales, marketing and software-as-a-service experience in oil and gas, Marino developed Pak Production to tackle the challenges producers face in capturing timely and accurate field data and allocating production. Before launching the platform, he spent several years at Waterfield Technologies, which provides consulting services and software designed to help companies improve customer service.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.