Technological Innovations Drive New Capabilities In 3-D Acquisition, Interpretation

By Kari Johnson, Special Correspondent

Over the past several years, the geophysical sector has been impacted by a series of “disruptive changes,” some more momentous than others. But there is little doubt that unconventional resource plays are at the top of the list of high-impact changes.

While geophysical surveying remains key in conventional and offshore exploratory drilling both at home and around the globe, the nature of resource play development has driven a complete rethink of the role of geophysics as it relates to tight oil and shale gas reservoirs. In short, geophysics has had to learn new tricks to extend the exploration-minded technical knowledge, technologies, and datasets to the domain of reservoir development and well completion.

So as with other oil and gas operational areas, shale plays largely have rewritten the textbook on reservoir geophysics. The seismic acquisition, processing and interpretation space continue to innovate and advance technology with clear economic benefits. This trend is particularly seen in geophysics, which maximizes drilling success rates, optimizes reserves recovery and increases bottom-line asset performance. Advances in geophysics are seen whether targeting a conventional sandstone in western Kansas, a deepwater Tertiary structure offshore West Africa or stacked tight oil benches in West Texas.

Tom Smith, president and chief executive officer of Geophysical Insights, says technological innovations are occurring across every facet of geophysics. In onshore acquisition, both conventional recording methodologies and broadband signals have improved, providing higher resolution and sampling densities for dramatically enhanced 3-D data quality. Offshore, marine vessels are being called back into service utilizing wide-azimuth streamers for high-fold coverage. Similarly, processing has improved in step with surveying designs, driving faster migrations and cost efficiencies.

However, according to Smith, the most exciting developments are arguably in interpretation, where computing power is being applied through cloud technology to evaluate unconventional plays to maximize their potential efficiently. With commodity prices on a tear and activity gradually on the rise, oil and gas companies have a tremendous opportunity to leverage technology in new ways to maximize well economics.

“The experience of 2020 demonstrates that office locations are malleable; many jobs can be done remotely,” notes Smith. “That includes the job of the seismic interpreter. When you combine digital-enabled processing workflows with computing scalability and the data security available through the cloud, you create a highly adaptable and economic situation that makes cross-functional teamwork and collaboration much more straightforward.

“Cloud computing makes it easy to process and interpret anywhere around the clock,” he continues. “While data sharing can be complicated, it is well understood and is not hard to work out.”

Technology Advancements

Smith points to drones and the Industrial Internet of Things as the biggest developments in land-based seismic acquisition. Long-life batteries and wireless Internet connectivity dramatically improve efficiency and data recording quality, creating a new class of simple yet highly functional IIoT-based wireless 3-D geophone.

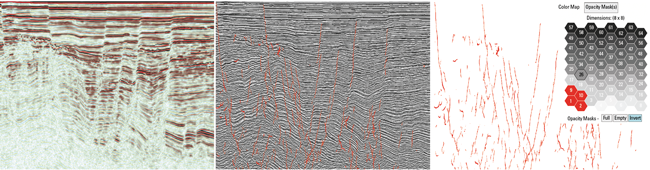

Shown here is a representation of an AI-based fault detection workflow using convolutional neural network (CNN) and self-organizing map (SOM) machine learning techniques in series. At left, is the original seismic amplitude. The center image shows SOM applied to CNN and instantaneous attribute volumes, producing fault neurons (red). The third panel shows the four fault systems isolated. The interactive 2-D color map shows an 8 x 8 neural topology (hexagonal neurons), enabling isolation and analysis of fault neurons. Seismic data from Opunake Basin, courtesy of the New Zealand Petroleum Ministry (NZPM).

“Deployment is easier, and data is collected at the best time for the highest quality,” he explains. “There are fewer dropped stations, and any issues with receiver nodes are quickly detected and addressed. Drones were first used in hazardous areas, but they are proving to have widespread potential for aerial data surveillance.”

In the area of processing, Smith says he has been watching exciting results obtained by geoscientists using digital twinning algorithms to compare recorded seismic data with mathematical models of the Earth to predict future earthquakes. The model is updated continually to fit real-world data and makes modeled predictions ever more accurate. Ultimately, he suggests, digital twinning will find its way in petroleum geophysics to improve seismic modeling and simulations.

“This type of methodology would help us better define risk, assess dynamic field or reservoir conditions, and determine the minimum and optimum operational parameters,” he relates.

Regarding interpretation workflows, Smith says artificial intelligence and machine learning have evolved into commercial tools that result in faster and less expensive interpretations and are proving to yield better results.

“The breakthrough was the realization that machine learning could be used to find patterns and allow the algorithm to self-learn without operator input,” Smith offers. “That allows the user to guide the interpretation process, or even allow the process to run unsupervised. By using machine learning to do tasks such as horizon picking, seismic interpreters can innovate rather than spending their time doing repetitive and tedious manual picks.”

Machine learning is also highly effective at detecting patterns in datasets, which is particularly valuable in applications such as merging multiple 3-D surveys, modeling seismic properties and identifying subtle seismic responses using well log data. Smith points to bivariate statistics to correlate neural responses from machine learning to reservoir properties as an example of how AI is used in unconventional and conventional development.

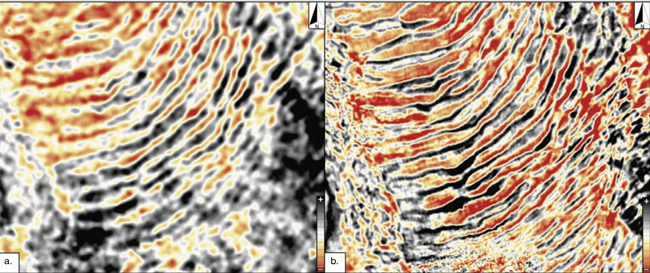

Fairfield Geotechnologies is acquiring new high-trace density 3-D and reprocessing existing data using advanced depth imaging techniques. These stratal slices compare conventional seismic data acquired in 2009 (left) with high-trace density data acquired in 2019 (right). The images show the toe of a mass transport deposit in the Upper Leonard formation in the Midland Basin.

“In our case, Machine learning algorithms are calibrated with bivariate statistics to tie detailed stratigraphic patterns with perforation zones for reservoir evaluation,” according to Smith.

Machine Learning

Smith describes machine learning as a seminal event in the evolution of data-intensive computation, creating powerful capabilities. “Rather than using code to grind away on batch computations, there was a fundamental step forward when we realized that you could write computer algorithms that adapt to a set of data,” he explains. “That’s machine learning–a step up in computations as profound as the digital computer.”

And the pace of development of adoptions of machine learning applications continues to accelerate, Smith goes on, pointing out that pattern recognition and classification are fundamental to making 3-D interpretations of subsurface features such as faults.

“Machine learning can do an excellent job of tracking major faults and is accurate enough to build sealed reservoir models for fluid simulators efficiently,” he remarks. “An extension of fault detection that is being applied in several basins worldwide is fault probability techniques that use the standard set of instantaneous attributes typically used with unsupervised machine learning. The advantage is that faults and detailed stratigraphic features are classified together.”

Looking forward, Smith says several promising research areas will likely drive the next round of advancements in AI and machine learning in upstream oil and gas. These nascent developments include automated recognition of seismic anomalies, fault classification to classify the geometry of fault surfaces, throws, and heaves, and seismic facies classification around boreholes. These subsurface features first are classified by machine learning and then automatically organized into geobodies and classified again by shape, thickness, areal extent, etc.

But what about the geoscientist? What kinds of skills will the interpreter of tomorrow need? “Interpreters will have to be part data scientists, but it’s easier to teach AI/ML to a geoscientist or engineer than to teach a data scientist about geology, geophysics or petroleum engineering,” Smith responds. “A data scientist will continue to focus on applying a set of general-purpose tools to a variety of problems. Geoscientists will focus on applying AI/ML to resolving a specific and unique problem: seismic data.”

High-Density Surveys

Resolution and density are the operative words in 3-D land survey designs as operators acquire data to fill gaps between existing datasets or extend the boundaries of existing survey areas, says Steve Jumper, chief executive officer of Dawson Technologies. “There is a clear trend toward tighter and more densely packed survey grids using cableless receiver array,” he notes. “The projects we are seeing are designed to fill in data holes, and as such need tighter spacing, higher sampling intervals and more density.”

Some of these “in-fill” surveys are in areas that have not been shot in some time. The Permian continues to be a strong focus for Dawson, and Jumper anticipates a potential uptick in natural gas basins Henry Hub prices remain strong. “The more data we can supply for processing and analytics the more the end-user can benefit during drilling, geosteering, and in fill planning,” he says.

Delaware Basin Datasets

Fairfield Geotechnologies just completed the reprocessing of 3,000 square miles of 3-D data in its library covering the Delaware Basin surveys, using advanced depth imaging workflows, according to Elaine Mattos, senior vice president, chief marketing officer and head of geosciences.

Fairfield has refocused on the U.S. onshore, adopting an asset-light business model that centers on multiclient land surveys. The company’s largest database is in the Permian, where acquisition of high trace density (HTD) data combined with high-end imaging algorithms is providing a new level of clarity on subsurface structures.

“The results of the HTD processing are incredible. We recently completed a broadband survey with more than 1,600 fold in the Midland Basin. We can see a clear uplift in complex structures from surface to basement,” Mattos enthuses, adding that the processed data images subtle features such as small faults that can impact everything from production rates to placement of saltwater disposal wells.

“Another trend we see is a move to full-waveform inversion,” says Mattos. “Many clients have acreage that is incredibly challenging in the near-surface. Surveys shot with high density and both low- and high-frequency provide the data needed for FWI.”

Infill 3-D Surveys

Paragon Geophysical Services is booking new surveying activity in projects in the Mid-Continent and Rockies, including a new 200-square mile survey in Northwest Kansas.

“With the oil and gas prices rising and a two-year project hiatus, acquisition projects should start to roll in again,” predicts Jaime Jimenez, product development manager in the company’s Wichita, Ks., office.

Jimenez says operators in Kansas, Nebraska, Oklahoma and Colorado are showing renewed interest in acquiring “Apron, halo, and buffer surveys that extend beyond the leasehold to get an idea of where the structure goes.” Well logs only tell part of the story, he explains. With seismic data, the operator can get the subsurface details needed to “follow the trend” with new well drilling or acreage leasing.

Paragon uses cableless nodes to make survey operations less intrusive and more efficient. “We are able to pass on the savings to clients,” he concludes. “It is a win for the land owner and the operator.”

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.