Advances Help Frac Teams Do More

By Colter Cookson

In a few short years, completion crews’ efficiency has risen dramatically. Today, it is no longer surprising to hear reports of a spread pumping for 72 hours straight, let alone 24.

The efficiency gains come from a variety of sources, including more robust equipment, data-driven efforts to identify and remove every second of unnecessary downtime, and extensive automation that is simplifying processes and driving repeatable performance.

Simulfracs are playing an increasing role by making the most of each unit of hydraulic horsepower. In fact, simulfracs have proven so successful that operators with enough activity and capital are completing three or sometimes four wells at the same time.

“The goal of simulfracs, trimulfracs and quatrofracs is to create more throughput,” notes Leen Weijers, senior vice president of engineering at Liberty Energy. “When a completion crew is pumping into multiple wells at the same time, the rate for each well decreases, but the overall rate goes up.”

That overall rate increase and the resulting gain in capital efficiency can be significant. “If a spread is pumping twice as fast across four wells as it would in a single well, it could reduce required pump pressures by 25%. That means only 1.5 times the horsepower is needed to pump at twice the rate,” Weijers illustrates.

The key is minimizing wellbore friction, which becomes more problematic as rates increase. “When we started Liberty 13 years ago, the average rate to pump a frac job was around 50 barrels a minute. Now the average is 100 or maybe 110 bpm,” he relates. “As the rate goes up, wellbore friction rises quickly and more horsepower needs to be on location solely to overcome the energy lost to friction.”

If a company reduces rates, as often happens in simulfracs and their bigger brethren, the results can be dramatic, Weijers assures. “Friction is almost a function of the square of the velocity, which in this context is the rate. Cutting the rate for an individual well in half will lower the friction by three quarters and reduce the required pump pressures by thousands of psi,” he explains.

To compensate for the lower rate in individual wells during simulfracs, Weijers says he generally recommends keeping the rate per cluster the same as for single well pump operations. He cites studies showing that wells’ production per foot increases with rate, fluid and proppant intensity, which helps explain why these parameters have gone up rapidly.

“If we reduce intensity by, say, spreading the reduced rate across more clusters, we will likely lose some of the productivity gains our industry has made,” he cautions.

Weijers attributes those gains partly to widespread adoption of limited entry perforating that ensures 80%-90% of the perforations receive fluid. “Not too long ago, we were only at 50%-70%,” he contrasts. “By shrinking stage spacing, simulfracs will be able to maintain that high perforation efficiency while pumping into more clusters in a given amount of time.”

To perform simulfracs and especially trimulfracs and quatrofracs, operators need multiple wells ready for completion. The technique therefore also possibly requires more wireline units, and adds to logistical complexity and flowline iron on location, Weijers notes. There is a trade-off between these extra costs and the capital efficiency associated with simulfracs’ potential to increase throughput.

Proppant

One development that is helping simplify logistics is growing acceptance of in-basin sand, Weijers mentions. “In-basin sand often is of a lower quality than traditional sources, but in many wells, sand quality seems to have very little impact on production,” he says.

Because local sand tends to be smaller, its adoption has accelerated a trend toward smaller proppant, Weijers says. Across the past 10 years, mesh sizes have gone from 20/40 to 70/140, he outlines. “With a proppant grain that is three times smaller, the terminal velocity is 10 times lower,” he calculates. “This helps the smaller particles travel farther into the fracture, which increases propped length. Smaller material also reduces the viscosity needed to carry and place the proppant, which may reduce chemical costs.”

Simulfracs are far from the only way the industry is minimizing costs, Weijers assures. “We are pushing for cleaner and cheaper fuels for every horsepower-hour,” he says. “The key is to run as much as possible on natural gas.”

The savings from using more natural gas can be stark. “For a typical well, spending on diesel can account for up to 20% of the completion cost,” Weijers estimates. “The exact amount varies, but if an operator has gas available, using it can significantly reduce the cost for every barrel of oil produced.”

Today, there are two ways for fleets to run entirely on natural gas. On pads with access to electricity from the grid or on-site generators, Liberty can deploy electric pumps. When electricity is unavailable, it can deploy pumps driven by reciprocating natural gas engines that have the highest thermal efficiencies in the industry, Weijers says. He points out that these pumps can be mixed with dual-fuel or diesel equipment when there is too little gas available to power an entire fleet.

Weijers says the natural gas-driven pumps pack considerably more horsepower into a trailer than traditional pumps. “The horsepower density also can help support trimulfracs or simulfracs operations, because it lets us increase the rate without needing a larger pad or more pumps,” he comments.

Electric Excitement

Interest in electric fracturing is at an all-time high, reports Nick Ruppelt, chief operating officer of Evolution Well Services, an all-electric pressure pumper that fielded its first fleet in 2016. “The decrease in footprint associated with electric fleets has been welcome as operators adopt simulfracs and trimulfracs, but the real draw is the fuel savings,” he assesses. “When a fleet runs on field gas, as we are in the Permian, Eagle Ford, Utica and Marcellus, the fuel savings are frequently upward of 90%.”

Running on field gas rather than compressed natural gas that has been treated elsewhere and transported to site can be tricky, Ruppelt acknowledges. “Field gas can contain contaminants that need to be removed, and its Btu value can swing wildly. On some pads, we have seen the field gas quality vary by the minute,” he relates. “Dealing with that variability requires us to tailor conditioning equipment to the site, watch for changes and respond quickly.”

All of Evolution’s fleets use turbines to generate electricity. According to Ruppelt, turbines lend themselves to running on field gas because they can tolerate lower-quality fuels than many engines.

In addition to significantly reducing fuel costs and emissions, electric frac spreads offer much higher horsepower density than diesel-powered fleets. To illustrate, Evolution Well Services points out that this fleet contains 84,000 horsepower.

“Turbines are a simple piece of equipment. They use a mostly mechanical operation to compress air, combust fuel and create power,” he describes. “This inherent reliability has been enhanced by decades of investment in other industries, including almost every type of power plant, from natural gas and coal to wind and hydroelectric. Turbines also serve as the engines for planes, where equipment uptime is non-negotiable.”

The power that the turbines generate goes to electric motors. Like turbines, Ruppelt says, these motors are extremely reliable. In many applications, they often run for decades without requiring maintenance.

Despite the underlying technologies’ broader track record, it takes time and expertise to adapt turbines for hydraulic fracturing. That is partly because fleets’ turbines need to be more mobile than the ones for many other use cases, such as stationary power generation, Ruppelt says. He adds that operating electric fleets requires skills that were once unnecessary on a frac site, such as working with medium-voltage equipment.

“Integrating power generation into the oil field isn’t a simple task,” he reflects. “Evolution’s philosophy of designing, manufacturing and operating our own power generation, electric frac and gas conditioning technology all in-house has been critical to our operational success. It has enabled rapid mobilizations and pumping efficiencies that match or exceed diesel and dual-fuel fleets while also providing fuel and emissions savings.”

In cold climates, waste heat from a turbine can be captured and circulated throughout the pad to warm wellheads, flowlines and other equipment, Ruppelt adds. “In the past, companies would use diesel heaters to blow hot air across the equipment that needs to be protected from freezing,” he says. “Our clients challenged us to create an emissions-free solution that also saves money. We designed an in-house solution to take advantage of the turbine exhaust heat to create value for our partners.”

The emissions reductions associated with running a fleet on natural gas rather than diesel are substantial. Citing third-party emissions stack testing and field measurements, Ruppelt puts the percentage reduction in greenhouse gas emissions somewhere in the high 20s. “There are many factors that influence the exact emissions reductions, but in general, turbines are a great solution for reducing emissions on pad,” he summarizes. “With data and legitimate emissions testing, we can help operators quantify that benefit in real time.”

In the long run, Ruppelt envisions all or most spreads moving to electric. “From a reliability and longevity standpoint, there is no reason every fleet should not be electric,” he argues. “How long that transition takes will differ from region to region, but as existing dual-fuel fleets age and eventually retire, the replacements will be electric.”

Automating Wireline

Wireline operations are an ideal candidate for automation, suggests Nadir Nery, president of Horizontal Wireline Services. “Our work is fairly repetitive,” he observes. “Through automation, we can let our employees in the field focus on staying alert and looking for potential risks rather than operating manual equipment. This improves safety and efficiency.”

According to Horizontal, one of automation’s biggest benefits is its ability to stop rare but potentially disastrous failures. “For example, automation helps us prevent unintentional pull-offs at surface, where the gun string parts from the cable and falls to the floor,” Nery says. “That is big, because in addition to reducing efficiency, a pull-off at surface can injure or kill someone.”

Electric units support automation by enabling faster and more precise control, Nery mentions. “If we still had to use the old hydraulic units, even an automatic response might not be fast enough to stop the winch from breaking the cable,” he says.

As electric wireline units’ automation becomes more sophisticated, jobs that once required manual guidance can be handled by machines. According to Horizontal Wireline Services, this transition is improving repeatability while allowing wireline supervisors to focus on the job as a whole and devote more time to preventative maintenance.

Automated wireline units also can prevent pull-offs down hole by limiting the torque on the winch and the speed, which controls the tension placed on the head, says Manuel Avitia, Horizontal’s vice president of technology and innovation. He describes automation as a gradual process, with many of the initial enhancements focused on minimizing manual work.

“The winch is controlled by a programmable logic controller that constantly verifies the operation is within tension and speed limits,” he says. “If a user accidentally pulls more than the allowable tension, it will filter out the input to stay within safe parameters.”

“Today, our PLC not only monitors speed and tension, but is also capable of automatically moving the cable to a specified depth within operating parameters,” he continues. “That lets the operator shift focus from directing the winch manually to making sure we are providing the correct instructions and that the logistics of the job are going the way they should.”

Easing the burden on wireline supervisors has helped improve safety and freed time for more diligent preventative maintenance, Avitia reports. In the near future, he envisions the wireline unit verifying that it is following the right procedures for a specific well and confirming that it is at the appropriate depth for each step by correlating the casing collar locator with the provided depth tally.

The units eventually will be able to manage the wireline spooling to protect the cable, Avitia says. “It will take time for us to get there,” he notes. “It is relatively easy to put the spooler where it needs to go, but verifying that the cable is wrapping correctly is a challenge.”

Reducing Downtime

Even at today’s automation level, the electric wireline unit is significantly improving reliability, Nery reports. “We began testing our first electric unit back in 2017,” he recalls. “Before, when we relied on conventional hydraulic units, we would see mechanical issues at a higher frequency. Today, we seldom have even one or two across an entire year.”

Since their introduction, the electric units have performed more than 100,000 runs, notes Blake Fenton, Horizontal’s vice president of quality, health, safety and environment. “The unit is raising the bar of what we can do reliably and safely in terms of tension,” he remarks. “As customers get comfortable with the technology and realize how well the automation handles downhole events, we are getting requests to pump down faster in areas where we used to be limited by tension.”

The data the units collect as they run is helping the company unlock other efficiency gains, Fenton adds. “Not too long ago, if a failure occurred on a wireline unit, the best minds in the field could meet to discuss what happened and still end up with speculation about the failure’s cause. Today, we can look at the data and know exactly what happened,” he reports. “The turnover rate for generating correct responses to incidents and implementing engineering controls to prevent them from reoccurring has gotten much faster, which is one reason we are seeing fewer failures across the board.”

The data also supports efforts to refine preventative maintenance programs, extend cable life and uncover other savings that ultimately benefit the customer, Fenton concludes.

While wireline providers and other service companies are making great strides by automating their own equipment, Nery stresses that realizing automation’s full potential will require equipment to share information across companies. To illustrate how that can be beneficial, he points out that certain well control valves should not close when a wireline is in the hole. By checking that the gun string is at surface before a valve is closed, automation and communication protocols between different equipment can prevent simple but costly mistakes.

“Service companies can be reluctant to integrate with other equipment on site because it may mean sharing proprietary information about their processes,” he acknowledges. “Getting over that roadblock requires trust and time spent crafting agreements that protect both sides, but it will be necessary if we want to continue to improve efficiency and deliver a better solution to our shared customers.”

Fortunately, Nery says, the industry is moving toward closer collaboration. “Other service companies are taking the same route. They are working on automation and thinking about how they should communicate with other parts of the operation,” he praises. “Operators also see the value. In fact, when we talk with them about our technologies, their biggest question is often not about reliability, but what we can do with other service companies to make sure everything is connected and running smoothly, which in turn benefits the entire industry by advancing safety and efficiency.”

Automating Perforating

Any process that can be automated on a horizontal stage completion wellsite is destined to be, predicts Adam Dyess, director of business development at Hunting Titan. “The industry has accomplished so much in the past few years,” he reflects. “Go out to almost any frac site today, and automated valves will make the connections between stages. When it’s time to deploy the wireline gun string, electronic e-winches and pumping units will guide the wireline down hole.”

Noting that he has seen less automation of perforating itself, Dyess says Hunting Titan has introduced a shooting panel that automatically fires the guns at the appropriate depths. “Normally, if we look inside the wireline unit during perforating, the user is pivoting between various functions. They are running the winch. They switch to software so they can communicate with the guns down hole, and they are physically handling the power supply, pushing buttons, and turning knobs as the operator stands behind them. All this takes place on the fly as the gun string comes out of the hole, so it can be stressful.

“With our automated shooting panel and available e-winches, the depths where the guns need to fire can be programmed into the unit ahead of the job,” he contrasts. “Once the guns reach bottom, the user presses a button in the software, and the winch will begin pulling the guns out of the hole. As each gun reaches its perforation depth, it will fire without any manual intervention.”

Modern self-oriented guns use tandem subs to rotate individual charge tube assemblies within the gun carrier rather than relying on external weights to rotate the entire gun string. When implemented well, this new approach dramatically increases accuracy, Hunting Titan says. The company cites field studies showing that the number of guns within 25 degrees of their target increases from less than 40% to 98%.

Because the data input into the panel has to be imported or typed in by a person at some point, there is a chance of human error, Dyess acknowledges. However, preventing that simply requires the software to verify that the data matches the plan for the well. “The panel assures operators there will be no off-depth perforations,” he says.

Self-Orienting Guns

With several published papers suggesting that oriented perforating significantly increases well performance, Dyess says it is becoming more common. “Today, 30%-35% of all plug and perf stage work in unconventional wells is moving toward orientation,” he estimates. “The vast majority of those orientation jobs are done with self-oriented guns rather than mechanical systems.”

That growing popularity is empowering gun manufacturers to deploy economies of scale and new technologies that reduce costs, Dyess indicates. “There used to be a significant delta between the price for a self-oriented system and a mechanical system,” he recounts. “That delta still exists, but it is much smaller.”

Self-oriented guns can improve orientation’s success rate significantly, Dyess reports. “In several downhole studies, mechanical orientation has proven far less reliable at shooting toward the desired location,” he explains. “For these studies, operators send cameras and ultrasonic sensors down hole after perforating to see the hole orientation, then compare that with the plan. With traditional locking hardware, fewer than 40% of the perforations are within 25 degrees of the desired orientation. With our self-oriented gun, that number improved to 98%.”

Both orientation techniques tap gravity to control where the gun points. However, the mechanically-oriented guns require additional hardware to be added to the string, such as locking mechanisms that keep the shots aligned with each other and eccentric weight bars designed to rotate the string. “With mechanical systems, we are relying on gravity and the bars’ weight to turn the entire string while it’s in the horizontal,” Dyess describes.

“Instead of hoping that external hardware can turn the entire string, self-oriented guns move control to individual guns. The design varies from system to system, but each gun carrier contains a bearing or other mechanism that allows the charge tube assembly to rotate within the carrier’s inner diameter. Since only the charge tube is working against gravity, it is much easier to point each shot in a predetermined direction.”

While the concept is simple, Dyess cautions that it takes care to get such systems right. “At first, one may assume they should go with a frictionless, free-spinning charge tube because it allows the guns to rotate more easily,” he says. “In the field, such unrestricted rotation ends up being a downside. As the gun string is pulled out of the hole, it slides across collars and other irregularities. With too little friction, these bumps will cause the charge tubes to swing and potentially shoot off depth.

“In other words, there is a fine line in the design and testing process to make sure the charge tubes can move easily enough for gravity to orient them but not so easily that they go elsewhere as the gun string moves up the wellbore,” he summarizes.

As with any gun, it’s also important to minimize the chance of misruns, meaning situations in which a gun-related issue forces the operator to come out of hole. “We are sending tens of thousands of guns down hole every month, and our failure rate is in the 1-in-10,000 range, so it is a very reliable system,” Dyess assures.

Interventionless Completions

As technological advances, consolidation and partnerships allow operators to drill longer laterals, more time must be spent pumping, setting and removing plugs. Reaching the final plugs in particularly long laterals may require larger coiled tubing units or workover rigs, which can increase costs significantly, says David Christmas, chief executive officer of Stage Completions.

Traditional ball drop sleeves can eliminate the time and equipment associated with plugs, but because the seats that catch each ball get progressively smaller toward the toe, they still need to be removed to free space for production equipment, Christmas continues. To eliminate the need for intervention, he recommends a collet-based completion system.

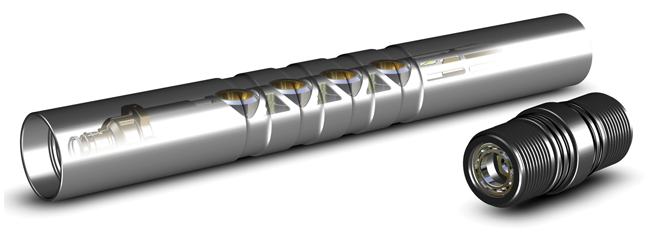

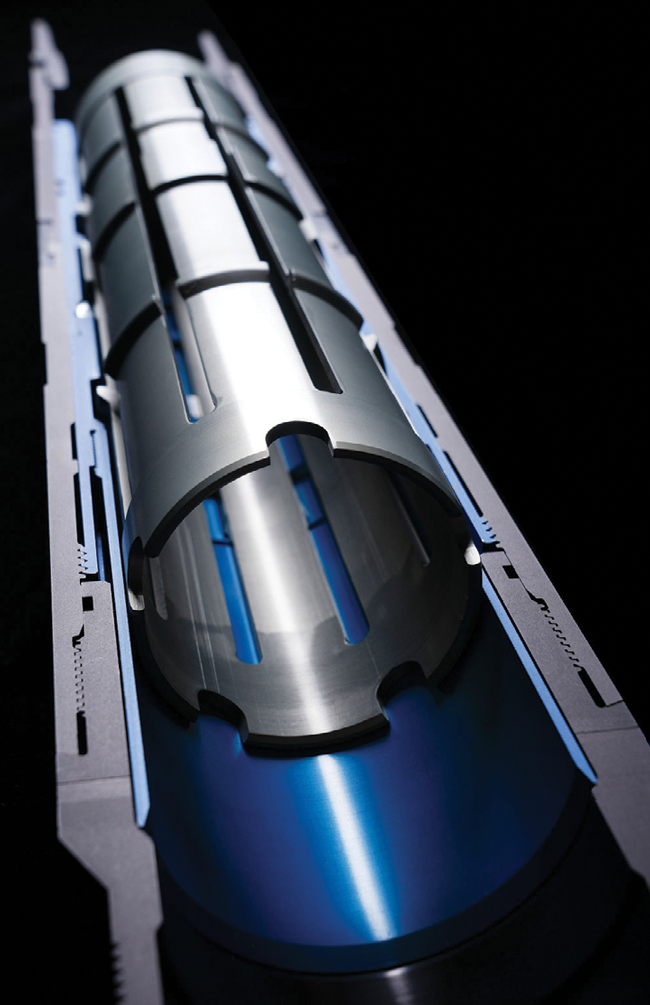

The collets used in Stage Completions’ interventionless completion system contain patterns on their exterior that allow them to open a specific sleeve (or for limited entry designs, a group of sleeves). Because the collets are thin, they barely restrict movement through the tubing, which usually eliminates the need to mill them out before putting the well on production. Coupled with other efficiency gains, Stage Completions says this helps crews complete wells faster.

Like ball drop sleeves, this system relies on dissolvable balls to isolate each stage from the lower portions of the well. However, instead of opening sleeves by placing balls into seats of the appropriate size, this system uses collets that all have the same inner diameter.

“Think of a collet as a thin cylinder with grooves cut into it that create a unique profile on the outside. This profile acts like a key for the valve it is supposed to open,” Christmas describes. “As the collet moves through the tubing, the exterior flexes in and out, pushing against the tubing until it reaches the valve with the matching pattern. At that point, it locks in place and opens the valve so pumping can begin.”

Once that stage finishes, the crew can initiate the flush and launch the next collet. “By the time the flush is done, the next valve will be open and the pumps can begin fracturing the next stage,” he says. “There is no need to stop pumping between stages.”

According to Christmas, that efficiency adds up. “In the Permian Basin, we can increase the average number of stages a day for a single well from 10 to 32,” he illustrates.

Reliability

Since the technology’s first deployment in 2016, more than 11,000 collets have been placed down hole, Christmas says. “For the past few years, the reliability has been nigh on 100%,” he reports. “The system is entirely mechanical rather than electronic, so it is less sensitive to temperatures or other issues that compromised some of the earlier sliding sleeves.”

Christmas adds that the dissolvable balls have been fully tested and work in all types of fluids.

The collet-matching sleeves cost more than the bare pipe used in plug and perf completions, Christmas notes. However, because they eliminate the need to pump plugs and guns down hole, as well as to mill out the plugs, he says they can take away the need to bring coiled tubing or wireline units on site. Moreover, he adds, the speedy process entails pumping less water and therefore fewer pumps on location.

“In many applications, the cost reductions associated with efficiency, less equipment and lower water consumption make the total cost comparable to that for a plug and perf completion,” he says. “In other applications, operators may rely on plug and perf toward the heel but use the interventionless system toward the toe, where it is particularly valuable.”

Because they reduce equipment needs, Christmas says interventionless systems can be attractive in areas with rugged terrain and small pads, such as the Rocky Mountains or the Marcellus and Utica. He adds that the systems excel in remote or international locations where it is difficult to get equipment, people or water.

While most operators initially use collet-based systems to replicate proven limited entry completion design, they often experiment with tighter spacing as they get accustomed to the technology, Christmas mentions. “Some of our customers favor single-point-of-entry designs that allow them to control exactly where the slurry and proppant go,” he says. “We have seen cases in the Permian where this approach delivered higher initial production and increased the wells’ estimated ultimate recovery 11%.”

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.