Enhanced Oil Recovery

Carbon Capture Boosting Oil Recovery

By J. Greg Schnacke, John Harju, John Hamling, James Sorensen and Neil Wildgust

PLANO, TX.–Chevron Corp. initiated the first large-scale enhanced oil recovery project in the world to use carbon dioxide as the working fluid in 1972 in the Texas Permian Basin. Four decades later in 2013, CO2 EOR contributed nearly 280,000 barrels a day of U.S. oil production from more than 100 sites. The U.S. Energy Information Administration reports that by 2017, U.S. CO2 EOR production had grown to 300,000 bbl/d.

In 2010, approximately 22 percent of the CO2 used in U.S. EOR operations was obtained from industrial sources. Additional EOR projects initiated since 2013 in Montana, Wyoming and Texas that also use captured CO2 confirm that the supply of anthropogenic CO2 is growing and suggest an increasing proportion in the total supply of CO2 for EOR.

The potential to deploy carbon capture technology at greater scale across power generation and other industrial sectors may provide an opportunity to proliferate both the number and geographical distribution of CO2 EOR operations, which could boost domestic oil production. Several oil producers such as Denbury Onshore LLC are expanding EOR operations already to capitalize on the use of these new anthropogenic CO2 sources as they become available.

CO2 EOR

CO2 EOR is a proven process that produces significant incremental oil and–inherent to the production process–results in safe, secure, long-term geologic storage of CO2 in legacy hydrocarbon reservoirs.

CO2 EOR projects are driven by the economic benefit of producing oil that cannot be recovered commercially through primary and secondary (i.e., waterflood) production methods. CO2 EOR is most commonly applied during the tertiary production phase of producing conventional oil reservoirs (i.e., after the reservoir has been depleted economically utilizing primary and secondary recovery).

CO2 EOR projects are initiated when the relative value of increased reserves and incremental hydrocarbon production exceeds the costs of acquiring the CO2, and installing and operating the associated infrastructure for a commercial project. This value proposition is improving steadily in the United States, which had 136 active commercial CO2 EOR projects as of 2014, with predictions of strong future growth.

Implementing CO2 EOR can extend the life of oil fields where the financial, public policy and environmental commitments to produce energy already have been made. Fields where such commitments have been in place historically may have reduced risk and uncertainty with respect to gaining corporate and regulatory authority going forward.

In many circumstances, these legacy fields correspond with significant technical knowledge bases that improve confidence in the assessment of CO2 EOR project viability and performance. Likewise, this knowledge base can reduce operational risk and inform management once projects are under way.

Associated Carbon Storage

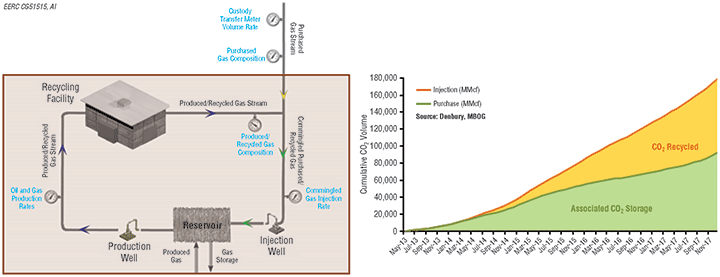

During CO2 EOR, injected CO2 swells and mobilizes oil not recovered through primary and secondary processes. Some of the injected CO2 is produced along with the newly mobilized oil. The produced CO2 is separated from the oil and water, dehydrated, compressed, combined with new CO2 being supplied to the field, and subsequently reinjected as part of the EOR process (Figure 1).

FIGURE 1

This process flow diagram and cumulative carbon dioxide injection plot illustrates the movement of CO2 storage occurring in association with Denbury Resources’ commercial enhanced oil recovery process at the Bell Creek oil field in southeastern Montana.

Studies show that virtually all the CO2 supplied to (or purchased for) an EOR project remains safely and securely stored within the geologic formation. Using anthropogenic CO2 for enhanced oil recovery, such as from a coal-fired power plant, is considered a form of carbon capture, utilization and storage (CCUS).

The CO2 storage inherent in EOR also is referred to as “associated storage.” Associated storage is considered by many environmental and energy policymakers to be a technically and economically viable means by which greenhouse gas emissions can be reduced.

An EOR project at the Denbury-operated Bell Creek oil field in southeastern Montana provides an example of how applying anthropogenic CO2 can result in incremental oil recovery and associated CO2 storage. The anthropogenic CO2 for the field is sourced from the Lost Cabin and Shute Creek natural gas processing facilities in Wyoming, and is transported to the Bell Creek oil field by pipeline.

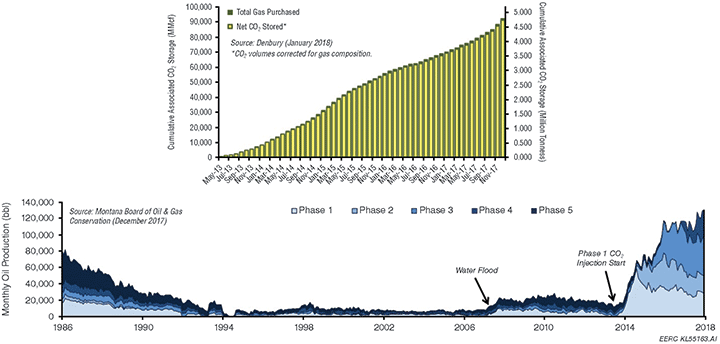

Between the beginning of CO2 injection in May 2013 and December 2017, more than 4.8 million barrels of incremental oil have been produced from the field, resulting in more than 4.8 million metric tons (tonnes) of associated CO2 storage (Figure 2).

FIGURE 2

Cumulative oil production and associated carbon dioxide storage are shown since the start of CO2 EOR at the Bell Creek oil field.

CO2 Utilization

Metrics used by reservoir engineers to determine the efficiency of CO2 EOR include CO2 utilization factors, CO2 retention and incremental oil recovery. These factors may be important parameters in assessing associated storage potential that may be realized by existing or new CO2 EOR projects.

A study conducted by the Energy & Environmental Research Center (EERC) at the University of North Dakota examined CO2 utilization rates at 31 CO2 EOR projects. The results show that CO2 utilization rates tend to be greatest near the beginning of the flood as the reservoir begins to fill with CO2. As CO2 EOR projects mature, the proportion of CO2 recycled increases and CO2 utilization rates begin to decline, typically reaching a ratio of between 4.8 and 10.5 Mcf per barrel of incremental oil produced.

Utilization rates for the Bell Creek Field, which is being developed in a staged approach (i.e., new geographic development phases are being brought on line periodically), are trending in line with typical early-stage performance observed for the EOR fields in the study.

As the Bell Creek project matures and the potential to develop additional phases is exhausted, utilization rates will begin to decline, resulting in a reduced rate of associated storage. This could result in an increased CO2 supply that could be diverted to a new EOR prospect.

In total, CO2 EOR at the Bell Creek Field is expected to result in 40 million-50 million barrels of incremental oil and is forecasted to result in upward of 15 million tonnes of associated CO2 storage.

Size Of The Prize

EIA’s 2018 Annual Energy Outlook forecasts U.S. production from CO2 EOR will grow to 390,000 bbl/d by 2025. Literature suggests the potential for CO2 EOR from conventional oil fields in the United States is substantially larger than that projected by EIA.

A U.S. Department of Energy-funded study by Kuuskra and others (2013) concluded that, assuming an oil price of $85 a barrel and a CO2 price of $40 a tonne, applying “next generation” CO2 EOR technology could yield 100 billion barrels of economically recoverable oil. That study also estimates the volume of CO2 required to recover 100 billion barrels of oil is 30 billion tonnes, which is equal to 35 years of CO2 emissions from 140 gigawatts of coal-fired power.

To date, commercial CO2 EOR has been applied almost exclusively to conventional oil reservoirs. Unconventional reservoirs, including tight oil systems such as the Bakken in North Dakota or residual oil zones, offer considerable increased potential to use CO2 for enhanced oil recovery, subject to developing the appropriate advancements in technology.

Studies conducted by the EERC, including field trials, have shown initial promise and underline the potential of these future EOR applications. EERC results suggest the size of the prize for CO2 EOR in the North Dakota portion of the unconventional Bakken petroleum system ranges from 1.8 billion to 16.0 billion barrels of oil.

Meanwhile, the success of rich-gas injection EOR pilots in the Eagle Ford play demonstrates that gas-based EOR in unconventional oil formations is both technically and economically viable. Laboratory studies conducted at the EERC, including miscibility studies, show that rich gas and CO2 appear to have similar effectiveness in mobilizing oil from tight formations.

As industry further develops and refines strategies to implement gas-based EOR in unconventional reservoirs and sources of rich gas become constrained, the concept of using CO2 as the working fluid for these projects will be become more attractive.

Broad implementation of CO2 EOR not only will add to U.S. oil production, but the associated CO2 storage will reduce the carbon intensity (CI) of that portfolio. Reducing CI has been a goal of American energy policymakers since President George W. Bush directed DOE to establish the Regional Carbon Sequestration Partnership Program in 2002.

CCUS can result in reducing the CI of produced oil because virtually all the injected CO2 ultimately remains stored in the subsurface rather than being emitted to the atmosphere. The stored CO2 will offset a portion of the net GHG emissions from the industrial source of the CO2 and the combustion of the hydrocarbon being produced.

An analysis undertaken by the EERC and published in peer-reviewed literature shows that the CI of the oil produced through CO2 EOR is less than that of conventional oil production. For example, average GHG emissions associated with gasoline and diesel produced from oil generated by applying EOR using CO2 sourced from coal-fired power generation are approximately 15 percent less than that of burning such products derived from crude oil with national average CO2 emissions characteristics absent offsetting associated storage.

The reduction in GHG emissions is attributed to the associated storing of CO2 in the oil reservoir as part of the EOR process, giving rise to an emission reduction of approximately 450 kilograms of CO2 stored per barrel of oil produced.

Gas Processing Scenario

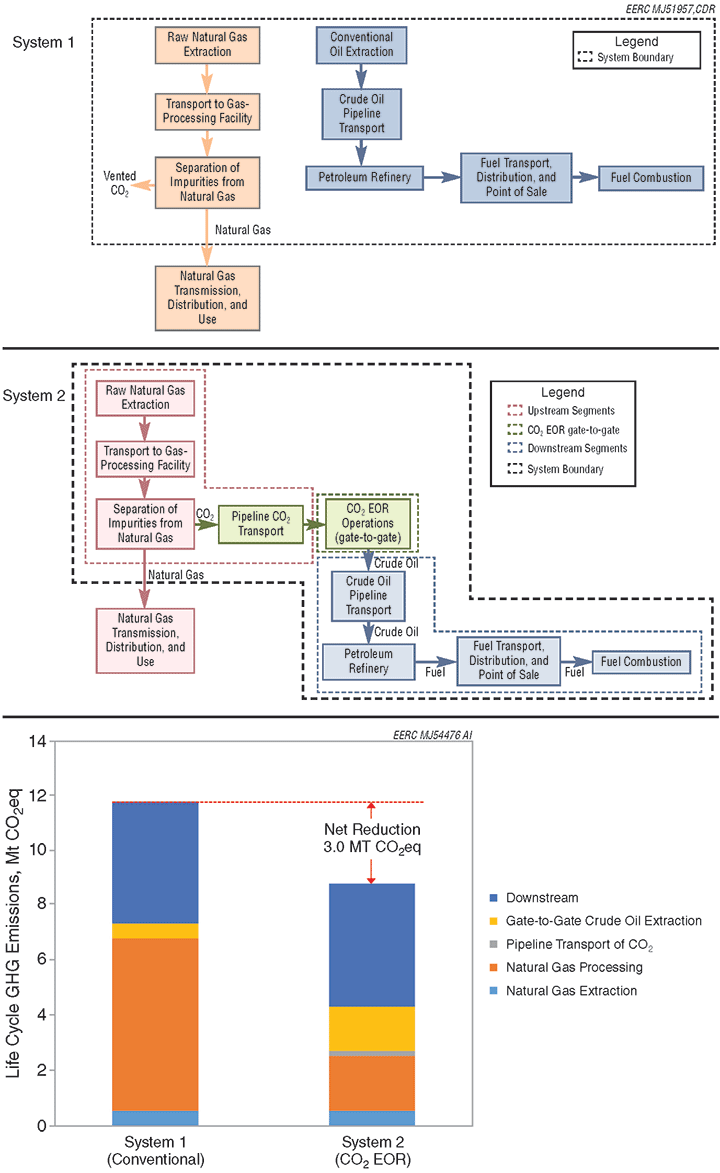

A subsequent analysis was undertaken by EERC to examine CO2 EOR scenarios employing CO2 captured from natural gas processing. This analysis modeled the CO2 vented to the atmosphere during gas processing and a CO2 EOR scenario analogous to the Bell Creek CO2 EOR project operated by Denbury. The study incorporated facility-specific data on the raw natural gas composition entering a processing facility and the emissions from natural gas processing, including vented CO2.

FIGURE 3

Greenhouse gas emissions for a base-line conventional natural gas processing system (System 1) that included conventional oil production and gas processing are compared with System 2, in which incremental oil is produced using carbon dioxide-enhanced oil recovery, and the CO2 is captured from the gas processing facility.

In addition, estimates used for associated CO2 storage incorporated both operational data from the Bell Creek project and from numerical simulation models calibrated to known performance data. As seen in Figure 3, the analysis compared GHG emissions for a base-line conventional system (System 1) against a system with incremental oil produced through CO2 EOR using CO2 captured from a natural gas processing facility (System 2).

Results suggest CO2 EOR using CO2 captured from natural gas processing produces both natural gas and oil with an 18-31 percent reduction in CI, compared with separate systems producing both oil and natural gas.

45Q Tax Credits

Changes in the U.S. Tax Code may provide additional incentive for operators to consider developing CO2 EOR projects. The Bipartisan Budget Act of 2018 amended the federal tax code to expand and extend Section 45Q tax credits for carbon storage. These 45Q credits were created to incentivize investments in carbon capture technologies in order to reduce the nation’s carbon footprint.

The value of the tax credit varies, based on whether the CO2 is captured specifically for sequestration, where eliminating anthropogenic CO2 emissions is the primary purpose, or whether anthropogenic CO2 storage occurs as a result of an EOR operation.

At present, the 45Q credit for CO2 used in a qualified EOR project is $15.29 a tonne. The credit increases linearly on an annual basis until 2026, when it reaches a maximum of $35.00 a tonne.

The credit for CO2 injected into deep saline formations as part of a qualified geologic storage project is set at $25.70 a tonne presently. It increases linearly to a maximum of $50.00 a tonne in 2026. After 2026, these amounts are to be adjusted for inflation. Only CO2 that is stored within the formation may benefit from the tax credit.

45Q tax credits can be claimed for 12 years after operations begin for qualified projects that begin construction before Jan. 1, 2024. The credits may be claimed by the taxpayer capturing the emissions, but emitters may be able to transfer them to the operators of intentional storage or CO2 EOR sites.

One key element of the revised 45Q rules is that participation thresholds for non-electricity-generating industrial facilities have been lowered from a minimum of 500,000 tonnes a year to 100,000 tonnes. This lower threshold allows additional industrial sources, such as many ethanol plants, to be eligible for the tax credits. These incentives may contribute to an increased supply of CO2 at a competitive price for use in EOR.

Work to make the credits more readily usable and aligning required reporting with applicable federal regulations and state resource conservation laws likely will contribute to faster proliferation and use of CO2 for EOR applications. Furthermore, clarifying the transferability of the tax credit likely will enable development of innovative business models that can realize the tax incentives and help finance new CCUS projects.

Reservoir Surveillance

Earning the 45Q tax credits requires an accounting of the stored CO2. The amount of CO2 stored during an EOR project can be calculated by monitoring CO2 production and injection rates, and subsequent validation through reservoir surveillance. EERC has been working with Denbury to better understand and account for CO2 storage associated with the Bell Creek EOR project.

Those efforts have resulted in reservoir surveillance techniques that can help meet the accounting requirements necessary to realize 45Q tax credits cost-effectively, but that also allow for the more prudent management of commercial EOR operations and improving project performance through better oversight and management.

CO2 EOR has the potential to partially address the energy demand/carbon intensity challenge by creating an energy system with a lower CI than one based on hydrocarbon energy produced through more conventional means. Deploying carbon capture technology at a greater scale can lead to proliferating both the number and geographical distribution of CO2 EOR operations. Applying industrially sourced CO2 EOR on a nationwide scale can produce a significant volume of incremental oil with an overall reduction in GHG emissions.

Although not the primary purpose of CO2 used in enhanced oil recovery, the value of associated storage may be increased significantly by the Section 45Q tax credits. Programs such as these have the potential to incentivize capture and storage of CO2 from anthropogenic sources as a way to reduce carbon emissions.

Expanding and clarifying the transferability of the tax incentives may enable the development of innovative business models that can realize these incentives to generate financing for new CCUS projects. And increased CCUS activity will diversify and boost domestic oil production, improving the nation’s energy security and sustainability profile.

J. GREG SCHNACKE is executive director, governmental relations for Denbury Resources Inc., in Plano, Tx. He coordinates government affairs activities for Denbury’s senior executive team at the federal, state and local levels. Prior to joining Denbury, Schnacke was the chief executive for the Colorado Oil & Gas Association. He also served on the senior staff of former U.S. Senate Majority Leader Bob Dole, R-Ks., both in Kansas and in Washington, holding several positions including legislative director and deputy administrative assistant. Schnacke is a graduate of the University of Kansas and the University of Tulsa College of Law.

JOHN HARJU is vice president for strategic partnerships at the Energy & Environmental Research Center, where he leads efforts to build and grow dynamic partnerships with industry, government and research entities in support of EERC’s mission to provide practical, pioneering solutions to the world’s energy and environmental challenges. He is a member of the National Petroleum Council.

JOHN HAMLING is assistant director for integrated projects at EERC, where he brings scientific and engineering innovation to field demonstrations. His role is to implement pioneering solutions that facilitate the prudent development and use of fossil energy. One of Hamling’s primary focuses is to advance the commercial application of geologic carbon dioxide utilization and improved oil recovery in both conventional and unconventional oil plays.

JAMES SORENSEN is assistant director for subsurface strategies at EERC. His primary responsibilities are to conceive and conduct research projects related to oil and gas resource assessment, enhanced oil recovery, and geologic storage of CO2. Sorensen’s project experience includes working on CO2 EOR pilot tests in conventional and unconventional wells in the Williston Basin, and commercial-scale demonstrations in the Powder River Basin and Alberta.

NEIL WILDGUST is assistant director for geoscience and engineering at EERC, where he leads efforts to characterize and model the subsurface to support a portfolio of energy projects. Wildgust has more than a decade of experience in research management, including the Plains CO2 Reduction Partnership and the IEA Greenhouse Gas R&D Program's Weyburn–Midale CO2 Monitoring and Storage Project.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.