Chemistry Companies Pair Data With Foresight To Improve Well Economics

By Colter Cookson

The oil and gas industry rarely stands still. Today, drilling teams routinely deliver multimile laterals that would have broken records only a few years ago and pressure pumpers’ fleets send completion fluids down hole almost 24 hours a day. These efforts have unlocked such high initial production rates that corrosion induced by flow velocity has become a serious concern in some wells.

For the chemical companies that provide everything from completion fluids to production chemicals and waterflood surfactants, this ever-changing environment means a steady flow of new puzzles to solve. By combining modern testing procedures with increasingly sophisticated data from the field, they say they can work out those conundrums faster than ever.

Even so, close relationships with customers and frequent communication between sales teams and the research and development department remain essential, says Ryan Ezell, chief executive officer of Flotek Industries Inc.

“As the hockey player Wayne Gretzky says, you never want to skate where the puck is. Instead, you try to skate where it’s going to be,” Ezell relates. “In the world of oil field chemistry, that means anticipating future challenges 18-36 months ahead of time so you can get a strong solution ready before most people need it.”

Limiting Water Cuts

Today, Ezell says one of the industry’s biggest challenges is high water cuts in development wells. “Hydraulic fracturing pumps a massive amount of water into the formation. While some of that water returns to the surface, much of it gets absorbed by the rocks. This water imbibition potentially alters the reservoir’s physicochemical properties, restricting hydrocarbons’ ability to flow in low permeability pore spaces,” he explains.

“Early in a field’s life, larger space between wells helps minimize the impact that water imbibition from previous completions has on production,” Ezell acknowledges. “It becomes more significant as operators decrease spacing and reservoir pressures decline.”

Simulfracs can minimize interactions between wells because all the wells benefit from untouched rock and similar reservoir pressures, but Ezell points out that simulfracs require a substantial capital investment. “For operators who drill wells one by one and use the revenue from the early wells to fund the later ones, simulfracs are not an option,” he says. “To help these companies, we potentially need to use a different completion fluids package in a down-spaced or child well than we would in the parent. For example, the package may have surfactants that focus on modifying surface tension and account for the change in contact angle caused by wettability fluctuations resulting from water imbibition.”

The ideal fluid will vary from application to application, Ezell notes. Although the industry will likely never have a perfect answer to water imbibition, he says it is getting closer thanks in part to tools for analyzing past results and testing new ideas.

Applying Experience

Ezell mentions that Flotek has completed more than 20,000 wells in North America. “Our chemistry has shown time and again to improve the uplift in the first 25-plus months, which is helping operators improve the ROI in every well,” he reports.

To translate that experience into relevant recommendations, Ezell says the company has used artificial intelligence to group wells based on the:

- Completion fluid;

- In-situ water;

- Hydrocarbon characteristics, and

- Reservoir properties (e.g., the target zone, the percentage of breakup of the clay, and temperatures and pressures).

These groupings let Flotek base completion fluids for new wells on strong-performing analogs, he explains.

“We can look at everything from friction reducers to shale, scale and corrosion inhibitors to find combinations that should minimize formation damage and ultimately enhance the well’s performance,” Ezell says. “The AI tools’ recommendations are not the final word, but they give us a very specific target range in which to design laboratory experiments.”

Like their predecessors, Ezell says today’s experiments try to understand flow through the highly porous primary fractures that drive wells’ initial performance. However, they concentrate on understanding fluid, hydrocarbon and water interactions in the much smaller pockets of hydrocarbons around the main fracture. Ezell says these pockets account for most of a well’s production past the first month.

“The microfluidics tests involve looking at chips at a high magnification to check for emulsion blockages or other issues that can restrict connectivity,” he describes. “They also study how the completion fluid will interact with rocks’ heterogeneity in surface shape and chemical make-up, as these interactions can impact hydrocarbons’ ability to flow effectively. The goal is to release as many hydrocarbons as possible from the smaller spaces around a fracture.”

Ezell contrasts microfluidics with formation response tests. “With a traditional formation response test, we could spend anywhere from three-six months looking at various options for the completion fluid,” he says. “Today, by getting as much data as we can about the well and running it through our AI adviser, then performing microfluidics and various compatibility tests, we can consolidate that into a few weeks.”

Ezell points out that the microfluidics tests take place at reservoir pressures and temperatures rather than ambient conditions, which improves the correlation between test results and actual performance. Because the tests are done at a small scale, he adds, it’s possible to conduct several simultaneously and get results quickly.

“Microfluidics lets us do far less laboratory work but get much better correlation in results,” he summarizes. “We can run samples in three days that used to take three months, which accelerates our ability to test changes and ultimately leads to stronger completion practices.”

Post-Completion Data

Over time, Ezell predicts that completion optimization efforts will benefit from more detailed and frequent feedback after the well enters production. He says getting that data will be possible with the monitors developed by Flotek’s data analytics division, which analyze hydrocarbon, inert gas and diatomic gas streams by utilizing near-infrared and Raman spectroscopy techniques. According to Ezell, these techniques have accuracy mirroring that of gas chromatography (GC), but can be performed every minute in the field, allowing on demand, real-time measurements.

By providing constant feedback on field gas quality, this analyzer is helping a dual-fuel hydraulic fracturing fleet minimize fuel costs, Flotek Industries reports. Eventually, similar analyzers may be used to monitor wells’ production streams for warning signs of paraffin or other issues that can be resolved with the right chemical treatment.

Eventually, Flotek plans to use the monitors to improve production chemistry applications. “While the well is producing, we can watch the production stream’s composition for signs of paraffin or asphaltenes, then treat those issues before they require the well to be shut in,” he says. “Because the monitors take measurements every 30 seconds, we may even get to a point where we can automate the treatment process.”

The analyzers have several more immediate applications, Ezell adds. “The technology has advanced through the Environmental Protection Agency’s testing protocol and been approved to monitor methane flares,” he illustrates. “We also have it on more than 20 frac fleets to track field gas’ Btu. If the gas gets too rich and it’s no longer safe to use in engines or turbines, we can blend the field gas with compressed natural gas or temporarily switch to pure CNG.”

Based on a year in the field, Ezell says such changes prevent fires and damage to turbines or other equipment.

The latest application of the analyzers is measuring hydrocarbon quality at custody transfer points, Ezell continues. “Compared with periodic sampling, the real-time analyzers provide more precise and accurate measurements,” he says. “On almost every well we look at, we see a wide discrepancy between hydrocarbons’ actual value and the one that sampling or process GCs would suggest. In most cases, the higher-quality data increases the producer’s revenue.”

Dry Friction Reducers

As operators and service companies look for ways to streamline logistics and reduce their environmental footprints, they increasingly are transporting friction reducers as slurries or dry powders rather than emulsions, reports Chris Dilley, vice president of sales and technology for PfP Industries. “Five years ago, almost 70% of the friction reducers sold would have been emulsions, with slurries taking 20% and dry chemistries coming in around 10%,” he estimates. “Today, dry chemistry and slurries have significantly increased their market share.”

Dilley attributes these products’ growing popularity to an ever-lengthening track record. “The misconceptions that slurries can be difficult to handle or that dry chemicals require unreliable equipment have been disproven,” he relates. “At the same time, people are seeing the benefits.”

Right now, slurries’ biggest advantage over emulsions is the lower overall treatment cost. “On a per gallon basis, emulsions cost about 1.5 times less than a slurry,” he acknowledges. “Although a slurry is much more expensive per gallon, it typically has much higher activity, which oftentimes cuts the amount that needs to be pumped in half. At current prices, this reduces the total overall treatment cost for FR by about 20%.”

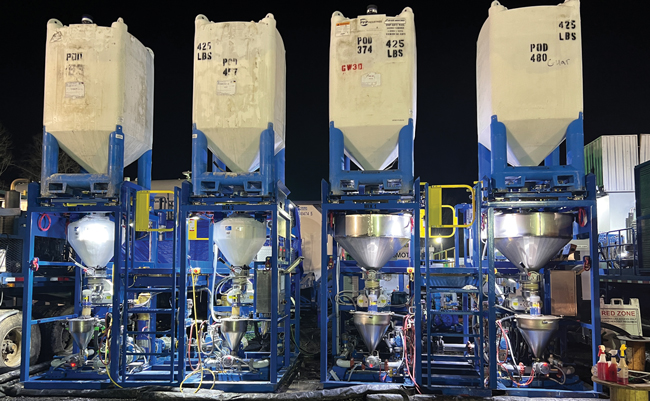

Thanks to advances in hydration equipment that minimize downtime, dry friction reducers are gaining popularity. PfP Industries explains that dry FRs reduce truck traffic, which improves safety and environmental performance.

But for most completions, Dilley recommends dry FRs. “Like slurries, they have a high activity level. However, dry FRs also have stronger environment, social and governance benefits,” he explains. “They eliminate the need to use mineral oil as a carrier fluid, and mineral oil is made with various carbon chains that the ESG movement aims to reduce.”

Dry FR also is more compact than liquid equivalents, Dilley notes. “If a pad requires 250,000 pounds of dry FR across a month, it will have 16 fewer trucks going to location than a standard emulsion,” he calculates.

“Taking another step back, removing the mineral oil from the equation also eliminates the need to transport the mineral oil from its manufacturing facility to the liquid FR’s production site,” he continues. “The hypothetical 250,000-pound treatment needs about six trucks of mineral oil, so in total, switching to dry chemistry takes 22 trucks off the road. That is a huge benefit for health and safety, because fewer trucks on the road means less traffic and potential for accidents.”

Since the dry FR can be delivered in pods on standard flatbed trailers, the trucks it requires generally cost less, Dilley adds. “For most jobs, there is a solid business case for dry FR,” he assesses. “However, for operations that pump only a small amount of polymer, such as new vertical wells with 15-20 stages, or many refracs, it can be easier to get an emulsion or slurry than to set up the equipment for hydrating dry FR.”

That observation holds even though hydration equipment is shrinking. “Historically, a guar or dry FR hydration model would need an area about the size of a semitruck, plus a pneumatic trailer. Think 40 feet by 40 feet,” Dilley describes. “Today, we only need a 12-by-8-foot skid to hold the hydration equipment and a 12-by-7-foot skid for a boost pump.”

The boost pump transfers the fluid from the hydration skid to the blender’s discharge side. “We used to send the concentrated FR through the blender, but that sometimes would cause the blender’s discharge pumps to cavitate,” Dilley says.

It is possible to automate the hydration skid and run it unmanned, but Dilley advises against that. “When we have someone on site who knows the equipment, the efficiency goes from about 70% to at least 95%, with many customers seeing 98% or 99%,” he explains. “In other words, there is almost no NPT associated with dry FR.”

Redundant Equipment

That reliability comes partly from redundant equipment, Dilley says. He points out that PfP’s units include two hydration systems. “If there is a problem with one, we can transition to the other without having to shut down the unit or stop the frac,” he relates. “In fact, in many situations, the frac crew does not even need to drop rate as the switch occurs. It can keep pumping and finish the stage on time.

“If both hydration systems go down, we are one of the few companies that has a fully independent liquid backup,” Dilley continues. “If something catastrophic happens on the dry side—say someone accidentally cuts a connection and it loses power—the liquid system steps in. It has its own power supply and contains the same polymer we use on the dry side in a mineral oil slurry.”

The liquid backup runs off a battery with six days’ capacity and the ability to connect to a variety of power sources, Dilley describes. He adds that the backup system generally holds enough slurry to handle four stages. “We have never run out of liquid before we can troubleshoot the dry side,” he reports.

Guar’s Potential

For sites that require guar, Dilley recommends hydrating it with a modified version of the dry FR skid. “We do not need the boost pump for guar, so the total footprint is about 12 by 8 feet, which is much smaller than traditional hydration systems,” he says.

Although total guar consumption has fallen alongside drilling activity in gassy plays such as the Haynesville, Dilley mentions that several operators have approached PfP about potentially using guar in more wells.

“The goal is to change the frac geometry,” he says. “With FR alone, even high-viscosity FRs, the fractures tend to be long but narrow. Cross-linked guar can produce much wider fractures.”

Given the costs associated with cross-linking guar, Dilley predicts guar is unlikely to displace FR, but suggests it may supplement it. “The industry may decide to pair the viscous modulus of guar, whether it is a cross-linked or linear gel, with the elastic modulus of FR to increase sand carrying capability,” he muses.

One point in guar’s favor, Dilley says, is its status as a natural friction reducer, “If we put guar in a flow loop at a concentration of four pounds per thousand and run it against a one pound per thousand produced water-type FR in West Texas produced water, the performance will be similar,” he says. “Guar has inherent drag reduction characteristics alongside its viscosity.”

Since PfP’s hydration unit for dry FR includes two blenders, it can handle two different polymers, Dilley notes. “In late 2022, we were the first company to put both FR and guar into the completion fluid with a single unit,” he says. “One side hydrated the guar, while the other hydrated the FR. The booster sent the FR to the missile, and the guar went into the blender as a linear gel, after which they would combine.”

That combination proved effective, Dilley relates. “It accelerated how quickly the pumps could get up to rate and increased the maximum rate they could achieve,” he details. “These benefits helped cut the time it took to put a stage away from five hours to about three.”

Good Problems

As operators drill longer laterals and optimize completion designs, many wells are achieving higher initial production rates. According to Justin Disney, the director of laboratory and research and development services at Jacam Catalyst, that accomplishment carries with it a new set of challenges.

“Operators are producing wells at a higher velocity and shear rate, which contributes to corrosion,” he clarifies. “In response, we are pushing the envelope on what corrosion control can do through new chemistries and application techniques.”

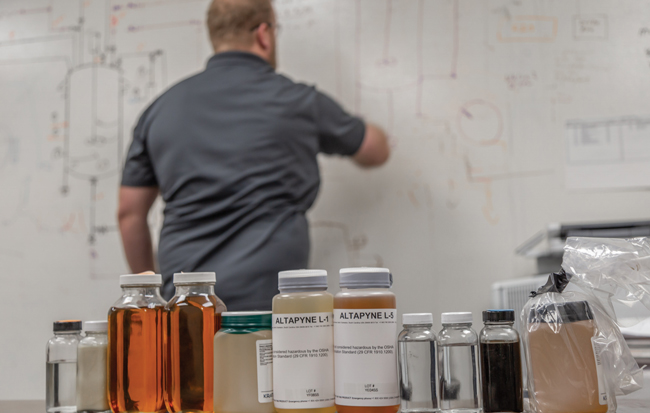

Developing these solutions requires finesse. “We need to strike a balance, because the best products for limiting corrosion may have detrimental impacts on fluid characteristics. For example, they can increase emulsification and make it more difficult to separate oil and water at the surface,” Disney relates. “We are looking for combination treatments that address corrosion without secondary effects.

To help operators meet more stringent pipeline specifications at an affordable cost, Jacam Catalyst looks at facility design changes as well as chemical treatments. The company adds that it is investigating novel chemistries with the potential to outperform traditional solutions in specific applications.

“In high velocity wells, the other issue is getting the product where it needs to be,” Disney continues. “We are testing more robust delivery techniques, then comparing the results with more capital-intense solutions, such as using corrosion-resistant metallurgies.”

To accommodate growing production volumes, pipeline companies are investing in drag reducers and other treatments that allow them to operate at full capacity. Despite these efforts, Disney says pipeline capacities often fall short of the oil volumes in search of transportation.

“Pipelines are getting pickier about the type of crude they are willing to accept,” Disney reports. “As a result, we are seeing more requests for help with post-production treatment to meet pipeline specifications. These treatments may focus on hydrogen sulfide, pH or mercaptans, as well as less-commonly tested criteria, such as organic chlorides.”

The treatments can be expensive, Disney says, noting that some add a couple dollars to the cost of each barrel. “That can have a big impact on economics, so we do what we can to minimize the cost,” he assures. “We start by looking at the analytical techniques used to determine whether the oil or gas meets specifications. Some techniques can be fraught with false positives, so we want to make sure they produce legitimate values.

“The next step is looking at the location’s physical constraints,” he describes. “Does the operator have the facilities in place to apply a treatment? How much contact time do we have? And are there any restrictions on the types of chemicals we can send into the pipeline? Based on this information, we work with the operator and pipeline to come up with an economic solution. Sometimes that means a new treatment, but it also can involve changing the facility design or moving to an alternative pipeline.”

Building Trust

In the years to come, Disney predicts chemical providers’ relationships with clients will be increasingly important. “As consolidation among operators and service companies accelerates, and as people age, we are seeing many traditional subject matter experts retire without being replaced,” he says. “At the same time, the number of assets the industry needs to manage is growing. These trends are creating more need for chemical providers to give guidance and advice.”

Customers without internal chemical experts often rely on third-party consultants to connect with the right company, Disney observes. “We are seeing more consultants today than we would in the past,” he says.

“For our part, we do a lot of training to help customers’ employees understand chemistry,” he continues. “We are also upfront and honest about what we can promise and what we cannot, as well as the information we need to make the best recommendations. It is easy to promise more than you can deliver, but that does not lay the foundation for a long-term partnership of mutual trust.”

According to Disney, helping customers identify the right solution for a particular problem is getting easier as testing equipment improves, computing power advances and access to information from outside the industry grows.

“Many of the most economic solutions to oil field challenges come from other industries,” he remarks. “It is usually cost-prohibitive to develop a molecule for a specific application if it has never been used before, because that molecule will have to clear numerous regulatory hurdles. Instead, we try to find a chemical that is already in use and expand its applications.”

During the pandemic, the search for novel chemistries accelerated as supply chain constraints blocked many traditional options, Disney recalls. In the right circumstances, the substitutes can eclipse their predecessors.

“We have seen that in hydrogen sulfide scavengers, where some of the triazine alternatives outperform triazine in specific situations,” Disney says. “For the past couple years, we have worked to understand these chemistries’ strengths and niche applications.”

That work is helping Jacam Catalyst diversify its supply base, Disney mentions. “For many traditional chemistries, such as ethanolamine, there are only a handful of plants that produce them or their precursors. If one of those plants goes down, it has ripple effects across the entire chemical industry,” he observes. “Because the alternatives tend to be produced at different facilities, they can help us keep costs low through supply chain disruptions.”

Accelerating R&D

Artificial intelligence systems that apply scientific principles can help chemical companies broaden their search for effective solutions, says Sunil Sanghavi, CEO of NobleAI. “For one of the world’s largest flavor and fragrance companies, science-backed AI led to a 20-time increase in productivity, a $5 million reduction in operational expenditures and $40 million in new revenue (as reported by our customer),” he illustrates.

While that example comes from a far different industry, similar benefits should be achievable within oil and gas, Sanghavi assures. He points out that NobleAI’s investors include Chevron Technology Ventures; M12, Microsoft’s venture capital fund; and Syensqo, a spin-off from the chemical company Solvay that focuses on specialty chemicals.

“The basic principle is that fast and accurate AI can turn computers into laboratories. A chemist, materials scientist or petroleum engineer can do thousands or millions of experiments in software to identify the handful of options that are worth testing in an actual lab,” Sanghavi outlines.

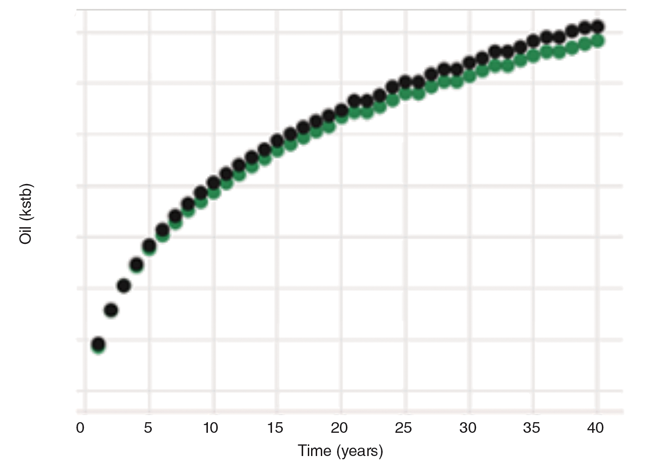

This graph compares oil production predictions from a traditional reservoir simulation (black) with those from a science-backed artificial intelligence ensemble (green) that is 5,000 times faster. According to NobleAI, such ensembles’ speed enables operators, chemical suppliers and other firms to evaluate numerous options quickly.

The virtual experiments’ results mirror real-world performance because they use laws of science to predict outcomes, Sanghavi says. Although these predictions will never be perfect, he considers, they are generated in mere seconds or microseconds, allowing companies to consider options that would be impractical to test under traditional constraints.

According to Sanghavi, this approach works even if a company has extremely limited data. As a case in point, he remembers work for a battery manufacturer that sought to improve its products. “It is costly and time-consuming to test batteries, so the company only had 400 data points to work with,” he recalls. “At that scale, many data-science-based techniques do not apply. However, by conducting virtual, AI-driven experiments, we created synthetic data and identified approaches likely to increase the batteries’ initial capacity and maximum number of cycles."

Almost all the recommendations involved parameters that differed greatly from the ones the company had previously tested based on its intuition and experience, Sanghavi mentions. “One of the strengths of science-backed AI is that it frees people to test counterintuitive ideas,” he comments.

Accurate Predictions

AI predictions only matter if people trust the underlying algorithms, Sanghavi emphasizes. “Our AI works in a way that allows us to point to what caused something to be reported as it was,” he says. “Instead of being a black box, it’s explainable.”

The company’s approach also has a track record of delivering realistic results, Sanghavi adds. “This is true even in the oil and gas industry, one of the most complex domains we work in,” he says. “For example, a U.S.-based multinational oil and gas company asked us to help it forecast how different decisions would impact production from a large play. When the company compared the predictions with historical data, they matched closely.”

In an SPE paper on its experience (AI-Powered, Lightning-Fast Production Modeling of Multi-Well and Multi-Bench Unconventional Development), the company reported that “the proxy model predictions accurately match the trends as well as magnitudes when compared to computationally expensive, high fidelity numerical simulations across several real examples of multi-well and multi-bench developments.”

The results also cost far less to generate than physics-based reservoir simulations, Sanghavi adds. To give a sense of the scale, he says the proxy models can produce data points in a tenth of a second, in contrast to the 10 minutes required for simulations running on expensive high-performance computing clusters.

But delivering rapid and reliable predictions is only possible with care and expertise. “Science-based AI is like making food,” Sanghavi compares. “Getting a fabulous dish requires great ingredients, a strong recipe and a chef who knows how to put everything together.”

For science-based AI, the ingredients include a series of models representing the laws that are relevant to the application, Sanghavi describes. “In the oil field, those models may cover reservoir temperatures and pressures, fluid behavior and various chemical interactions,” he comments. “The multinational company’s project accounted for more than 150 factors.

“For a simpler example, imagine a detergent company wants to add a new fragrance to its product line,” he illustrates. “It cares how the clothes smell if someone sniffs them immediately after the wash, and that smell needs to linger even if the clothes sit in the closet for a week. Those goals tell us we need to model laws of diffusion, or how the fragrance molecules dissipate in the air around the clothes, and the law of evaporation, which determines how the fragrance molecules move from the fabric into the air.”

With its proprietary tools, Sanghavi says the company selects the right models for the applicable laws from an ever-expanding set of options. “The dirty secret of AI is that it’s rare for the algorithms themselves to be proprietary,” he comments. “The AI world is filled with academics who need to publish or perish, so almost every algorithm is freely available on GitHub. However, it takes intuition and experience to know that a particular application calls for a Gaussian model.”

Once the right models have been identified, they are combined into an ensemble that will produce the desired outputs, Sanghavi continues. He says users can apply design constraints to the ensemble’s output or its constituents. “For example, we may tell the diffusion model that the temperature and relative humidity in the environment will fall within a specific range,” he says.

When it’s available, the ensemble will draw on empirical data. It also can consider simulation data. As real data comes in from the field, the ensemble can be retrained and improved, Sanghavi describes. Because each ensemble only exists for a specific application, he says, companies need not worry that their data will help competitors.

“The science-based approach to AI is general enough that we can apply it to almost any problem,” Sanghavi says. “In the oil field chemistry space, we may look at how different surfactants enhance the lubricity and stability of drilling muds, improve proppant transportation in completion fluids or mobilize trapped oil in enhanced oil recovery projects.”

Other applications for science-based AI include seismic inversion, stratigraphy modeling, well placement optimization, proppant selection and predictive maintenance on pumps, compressors and turbines, Sanghavi envisions.

“Depending on the complexity of the application, developing the ensemble can take anywhere from two weeks to six months,” he says. “It is an investment, but it can easily pay for itself by giving companies the ability to look at hundreds or thousands of scenarios.”

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.