ESG Movement Accelerates Evolution Of Safety Best Practices

By Monica Cervantes

When it comes to protecting employees and the environment, the oil and gas industry has long recognized that its work is never done. But investors’ growing interest in environment, social and governance metrics has made it more important than ever to keep track of best practices, training techniques and technologies that can help this essential industry protect the planet and its people.

In the upstream sector, the quest for more responsible operations touches every operation, from exploration, drilling and completion to production. By engaging in constructive conversations with their peers and stakeholders, operators and service companies alike are finding better ways to work.

One of the industry’s oldest tools, bentonite, may offer a cost-effective way to create strong, durable isolation. Bentonite has been used in drilling mud and geosynthetic clay liners for years. Outside the oil and gas industry, it’s also employed in wastewater treatment, agriculture, waterproofing, construction and even pharmaceuticals and cosmetics.

Bentonite’s appeal comes from its status as a 2:1 clay with a negative charge. Thanks to its chemical structure, which consists of one layer of tetrahedral molecules over a second layer of octahedral molecules, bentonite excels at absorbing water. It also has a unique isomorphic substitution capability. In other words, it can “switch out” cations, replacing one with another that resembles the original in size.

Recent published scientific papers have clearly highlighted and expanded on bentonite’s unusual capabilities. Based on this research, the familiar but wonderful material is being applied to remediate oil and gas wastewater, where it offers an eco-friendly and safer alternative to chemical treatment. Other work is investigating bentonite’s potential for plugging and abandonment operations.

Orphan wells, or ones that have been improperly plugged and abandoned, can impact plants, animals and humans negatively. When damage from corrosion allows communication between formations and the wellbore, soil can become contaminated, which can cause loss of vegetation. Contamination can migrate to the water table as well.

Bentonite clay (left) has a range of oil field applications beyond drilling mud, such as simplifying water treatment and strengthening plugging and abandonment operations. The versatile clay is produced at mines such as the ones shown to the middle and right.

Kyros Global Group, a supplier of custom bentonite, is helping meet the oil field’s need for bentonite. The company has opened offices in Midland, through which it can deliver custom bentonite from four mines in Mexico.

“Our vision is to link trade relationships across the border, with offices in Midland and Monterrey, Mexico, with quality, customized bentonite,” says Chief Executive Officer Isaac Diaz, who has dual citizenship in the United States and Mexico. “Bentonite is used in a variety of industries: oil and gas, agriculture, wastewater treatment, cosmetics and domestic use. Bentonite is a natural, ‘friendly’ clay produced from volcanic ash, and the benefits of use are endless.”

In water treatment applications, bentonite replaces or minimizes chemical use. In many oil field applications, it is effective enough to enable water to be recycled more often. In the public sector, municipalities need less chlorine once they deploy bentonite filters.

The research into bentonite’s effectiveness at plugging wells is motivated in part by the bipartisan infrastructure law President Biden signed last year, which authorized a record $4.7 billion for states’ efforts to plug abandoned wells. These funds have spurred states to invest more resources into finding abandoned wells within their borders. They have documented and reported more than 120,000.

Because these wells can leak harmful chemicals into the air, soil and water, they need to be plugged. Bentonite’s advantage is its longevity. While cement has a lifespan of around 30 years, bentonite is incredibly stable and resistant to moisture. These traits give it such a long shelf life that it technically never expires. As an eco-friendly, all natural material that is safe enough it can be ingested, bentonite is well-positioned to strengthen companies’ ESG scores.

Safety Innovations

As the industry works to become more sustainable, it is replacing hazardous chemicals where possible, minimizing employees’ exposure to other safety hazards and shrinking potentially harmful emissions. Since methane is a potent greenhouse gas, one area of focus is reducing methane emissions.

With that goal in mind, many companies are deploying drones with infrared cameras that can detect and quantify methane. In addition to identifying leaks as part of leak detection and repair programs, these drones’ data will guide development of controls designed to prevent emissions from occurring.

Performing effective and efficient drone surveys requires expertise. Service providers need to understand the strengths and limitations of their drones and the detection technologies they carry. Ideally, they should also know the oil and gas industry well enough to understand what the data they collect means and to explain relevant regulations.

Given drones’ rapid rise in popularity, training will be essential. Vertical Bearing LLC, owned by Derek Jones, has stepped up to provide drone consultant training designed in collaboration with a West Texas-focused environmental consultant. This training will help participants gain the regulatory and technical knowledge they need to provide valuable feedback to clients.

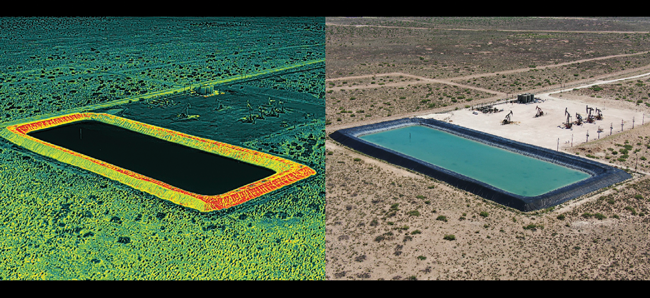

In addition to helping the oil field detect and quantify methane emissions, drones can produce striking images for investor presentations, sustainability reports and other communications. The thermal image on the left shows heat radiating off a hydraulic fracturing pond’s liner.

Drones also can evaluate concentrations of other concerning chemicals, such as hydrogen sulfide. The best way to protect employees from this deadly gas is to minimize their exposure to it, and that is getting easier as personal safety monitors improve. But it’s also vital to minimize the effects of any exposure that occurs despite our best efforts. With that in mind, one of my companies is developing a nasal spray that can be administered in response to hydrogen sulfide exposure.

The research is in its infancy, but it is worth continuing. The spray will give companies an exposure treatment that can be stored on site and deployed immediately after exposure occurs.

Technological advances also are helping with fire control. For example, Xtreme Tank Technologies, which is owned by Paul Gibbs, has developed a tool that floats on top of the oil inside production tanks. While it is installed primarily to capture vapors that would otherwise flash from the tank so they can be sent to the sales line, this tool is paired with a camera that looks for signs of a fire. If one is developing, the tool automatically deploys an extinguishing agent within the tank.

The safety benefits come alongside economic ones. Because the tool sits immediately above the oil, it can capture heavy, high-value gasses that rarely get high enough to be collected by roof pulls or vapor recovery towers. The more comprehensive vapor recovery reduces emissions while increasing revenue.

Empowering Workers

Even with the safest equipment available, working around hydrocarbons will always require situational awareness and caution. Training is essential to ensuring that workers notice potential risks and take the appropriate steps to mitigate them. Some of the most effective training programs blend classroom experiences with hands-on practice to build the skills workers need to complete tasks safely, efficiently and consistently.

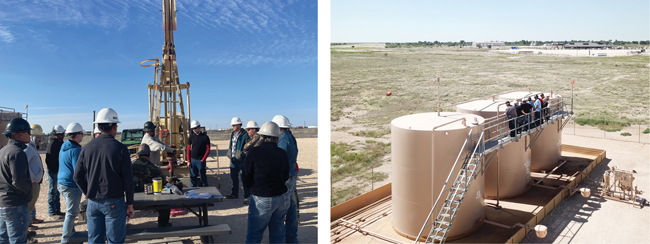

New Mexico Junior College’s lease operator course offers an opportunity to all interested in expanding their knowledge or participating in an oil and gas career. I have loved teaching it alongside Kelly Tooker and Don Harmon. It’s gratifying to guide and inspire students as they embark on their careers as lease operators to support their families and deliver the energy we all rely on.

Along with the NMJC lease operator course, New Horizons Foundation promotes and supports innovation within the oil and gas industry. As the college’s research arm, New Horizons looks for ways to bring economic opportunities and jobs to Southeast New Mexico and throughout the Permian Basin.

Seasoned pumper Don Harmon is teaching students as part of New Mexico Junior College’s lease operator program, which helps participants launch oil and gas careers or refine existing skills.

To accomplish this task, the organization has a cooperative research and development agreement with the U.S. Department of Defense that provides access to knowledge and patents from DOD labs that can be used in the oil and gas industry. The partnership also connects New Horizons with advanced manufacturing, materials and environmental technology.

New Horizons Foundation has developed concepts for sound-suppressing mufflers that decrease decibel levels as much as 50% by applying vortex knowledge. The technology originally was designed for hydraulic fracturing units, but the newest prototypes reduce noise from smaller generators, outdoor power equipment and even small tractors.

Another New Horizons project is a patented downhole tool for removing obstructions from perforations. By leveraging technology from U.S. Army research laboratories, this tool generates 2,500 psi to push water, acid or other chemicals into the obstructions at rates as high as seven barrels of a minute. This deployment technique will likely prove more effective than traditional scrapers. The Hydrotool is being tested in wells in the Permian Basin and surrounding areas.

New Horizons’ past endeavors include:

- Cold spray equipment to enable equipment repairs in the field;

- A coating for sucker rods that extends rod and coupling life as much as 17 times;

- A special paint that makes it easy to detect metal fatigue; and

- New battery technologies that store power in a smaller footprint.

According to Dennis Holmberg, the New Horizon Foundation’s executive director, future projects involve rig automation and expanding uses for produced water. If produced water can be treated and recycled outside the oil and gas industry, the industry’s environmental impact can be minimized even in areas with too little completion activity to justify a traditional recycling program.

The technologies discussed here represent a small but exciting sliver of the innovations occurring across the industry. Maximizing these emerging technologies’ potential will require collaboration and commitment. Fortunately, investors have made it clear they will reward companies that excel at protecting their employees and the environment.

But even without the ESG movement, the industry will take steps forward. History shows that assessing, evaluating, monitoring, mitigating and controlling existing and potential hazards can lead to practical solutions.

MONICA CERVANTES is the founder and CEO of Twin Horse Environmental. She is a World Safety Organization-certified safety instructor master level (ISO 17024) and WSO-certified safety technician who has authored articles for the “World Safety Journal.” Cervantes is a certified safety professional, associate safety professional and industrial hygienist. She owns Twin Horse Environmental, Vida Medical Management and La Chava, and she is a business partner in Kyros Global Group. Cervantes serves as the founder and chief executive officer of the Gracias Foundation, the president of the Odessa Multicultural Committee and a member of the WSO’s board of directors.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.