Automation & Measurement

Ubiquitous Metering Improves Profits

By Colter Cookson

With West Texas Intermediate crude oil prices hovering around $40 a barrel, producers are focusing on controlling costs. For many of them, this means finding ways to improve the efficiency of the treatment systems, gathering lines and processing facilities that help move oil and gas from the wellhead to the sales point.

Automation is playing a key role in those optimization efforts, but for automated decisions to make sense, they must be based on accurate and timely data. To get that data, equipment suppliers say, operators are paying for more instrumentation.

“For most of my career, surface facility engineers have been told to spend as little as possible,” says Larry Richards, chief executive officer of VanZandt Controls LLC. “During the past five years, we have seen more operators willing to make upfront investments in automated valves, flowmeters and other instrumentation that can give them feedback on pressures, temperatures and levels, because they can use that information to look at the entire system and drive efficiency.

Because they offer more precise control and greater reliability, oil field companies increasingly favor electrically actuated valves over pneumatic ones, VanZandt Controls LLC reports. On this pump and variable frequency drive application, a Valvcon® electric actuator is paired with a V-ball valve to maximize efficiency.

“This holistic approach can unlock dramatic reductions in downtime and overall costs,” Richards reports. “As a result, we have seen automation spread from skid-mounted equipment to surface facilities such as tank batteries and compression stations.”

As automation expands, Richards says electrically actuated valves are replacing pneumatic ones because the electric versions offer greater control and reliability.

“There is an environmental component as well,” Richards mentions. “Most pneumatic devices run on field gas and bleed to the atmosphere. By replacing them with electric actuators, operators are reducing their methane emissions. The reduction from individual valves is small, but across an entire facility, it’s significant.”

Although the electricity that electric valves require can be challenging to provide at remote sites, Richards says, rapid improvements to the cost and reliability of small solar packages have made the valves a viable option at many locations.

Emergency Shutdowns

Richards says the shift to automated electric valves is particularly important for wellhead emergency shutdown devices. “The wellhead gas generally used to pressurize pneumatic valves has liquid that can drop out in the line and freeze, blocking the line and keeping the gas from reaching the valve when it needs to close,” he explains.

Because of the serious risks associated with such failures, the industry is racing to adopt electric valves for ESDs, Richards reports. He adds that newer ESD designs are replacing slab gate valves with alternatives.

“A slab gate valve resembles a gate that slides down and connects to a slotted base. Sand can build up in the slots and prevent the gate from creating a complete seal when it closes,” Richards warns. “Since new wells have such high sand volumes during flowback, this can make slab gate valves unreliable.”

In response, VanZandt turned to a ball valve originally used in offshore projects and adapted it for onshore applications. “The valve saw use off shore because it can contain high pressures with low torque and has a superior close ratio,” Richards relates. “It also handles high sand volumes without washing and closes completely even in the presence of sand. Pair it with an electric actuator, and it provides a reliable seal.”

Controlling Backpressure

According to Richards, automated electric valves excel at holding backpressure on pumps, including ones used to move produced water and oil. “Maintaining the correct backpressure helps pumps stay on their efficiency curves and reduces cavitation and knocking, allowing the pumps to move more volume and extending their lives,” he says.

Although water transfer pumps are becoming more sophisticated, many companies still use manual ball or butterfly valves on the pump’s discharge. “Physically opening the valve to bring the pumps on line can be labor-intensive and creates safety risks,” Richards says. “Instead, we are putting in automated V-ball valves, which offer much tighter control over backpressure, eliminate extra work and often cost less.

“Our clients are getting similar safety and efficiency gains by automating wellhead choke and in-line choke valves for high pressure/high sand applications,” he reports. “In many applications, automating these valves reduces sand problems and flaring volumes.”

As operators and service companies look for ways to reduce costs, Richards encourages them to re-evaluate their automation technology. “In many cases, customers have standardized on equipment that is three-five years old and no longer offers the best value,” he says. “In others, they are paying for top-end equipment when they can automate their systems with less expensive options that are more robust and easier to service.”

Modular LACT Units

As product quality requirements have tightened and contracts between producers and purchasers have become more complex, the demands placed on lease automatic custody transfer units have risen, observes Gene Gradick Jr., senior vice president of SCS Technologies LLC. To provide LACT units that can achieve clients’ goals at an affordable price, he says some fabricators are offering modular designs that support several options for pumps, controls and other key components.

To help clients improve efficiency and implement increasingly complex contracts between sellers and purchasers, LACT unit fabricators are installing more sophisticated automation and control, SCS Technologies LLC shares. Modular designs and improvements in manufacturing are limiting the extra cost associated with these capabilities.

“Cost cutting initiatives, customer consolidation, centralization and clients’ desire for one point of contact at the fabricator level are accelerating modularization,” Gradick assesses. “Modular designs allow customers to meet application-specific goals while getting many benefits of standardization, including fewer repair parts, universal familiarity at the field level and the freedom to move measurement equipment to other areas as assets age.

“One of the drivers is private equity-backed midstream companies,” Gradick mentions. “We have helped several startups by supplying hundreds of units as they develop their systems and bring on new producers. For them, standardized and modular units are the best way to build a system on time while budgeting for and controlling costs.”

To support customers’ automation efforts, Gradick says LACT units are becoming more sophisticated. “Since SCS was formed in 2012, we have seen the price per unit increase every year as customers’ needs require more automation and controls,” he reports.

Increased automation often means more client employees are involved in LACT design decisions, Gradick notes. “As teams get larger, it gets easier for design creep to sneak in,” he cautions. “A LACT unit with almost every option can cost $400,000, but some customers can meet their goals with an $80,000 or $100,000 unit. We want to build long-term relationships, so we draw on our experience to help customers decide whether their situation merits buying a Rolls Royce or a Chevrolet.”

Factory Acceptance Testing

As part of the purchasing process, most LACT fabricators offer customer factory acceptance testing (FAT) through which customers can see the electronics and controls of the skid in action. Gradick says this testing is worth both teams’ time. When it is applicable, he recommends including a mechanical point-to-point test during the FAT.

“At SCS, we have the capability of providing a ‘flow or wet’ test where we run fluid through the unit so the customer can see it functioning in as close to field conditions as we can replicate in a factory setting,” he adds.

“One of the most interesting parts of the build process is when the field operators can put their hands on the design, because they often suggest tweaks to the ergonomics or usability that people rarely think of at design time,” Gradick continues. “In 2020 alone, we have made changes to containment, adjusted controls height and location, and raised platforms to match customers’ preferences and improve their ease of use and safety.

“SCS has taken a proactive role in alleviating customers’ challenges through the downturn,” he says. “One client had a project delayed and might need to hold off on installing pipeline metering systems for 6-18 months, so we are storing two metering skids it purchased. These skids need to run to stay in operating condition, so we have connected them to 480v power and are stroking the valves and rotating the pumps on a long-term maintenance schedule we have developed and the customer has approved.”

Gradick adds that SCS is making internal improvements to prepare for the activity rebound he speculates will occur in 2021. “We are taking the time to control our costs, increase our efficiency, and add processes and procedures to prepare for future growth,” Gradick details. “For example, we are investing in new equipment and continuously improving our manufacturing flow to limit how often we need to move each unit, which speeds the production process, enhances safety and produces a better product.

“We are finding creative ways to benefit our customers and keep our employees challenged during this downturn,” Gradick continues. “Most of our engineers and project managers have worked for producers, pipeline companies or repair and maintenance teams, so they understand clients’ business drivers and have hands-on expertise with LACT units. We are applying that experience to develop practical solutions.”

Product Quality

By allowing producers to make better decisions about where they sell their oil, gas and liquids, data on product quality can improve margins significantly, says Mark Le Dain, vice president of strategy for Validere Technologies Inc.

“Quality is often the underlying cause of low margins,” Le Dain argues. “Consider producers that miss their earnings estimates for the quarter in part because of high trucking costs. It turns out they have been getting shut in from the targeted terminal because of inaccurate vapor pressure measurements, which forces them to pay truck drivers overtime to go to other sites.

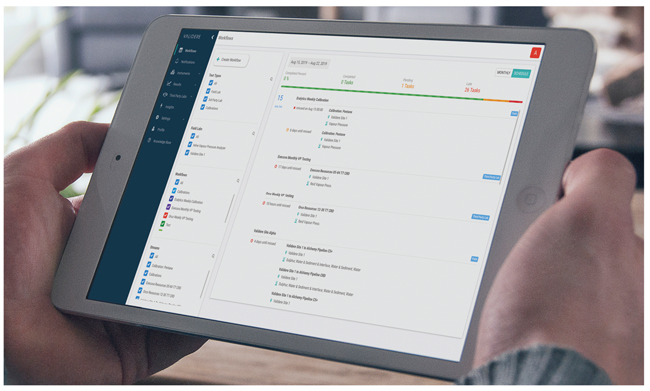

Through cloud-based modeling software, producers, midstream firms and refineries can validate meters’ product quality measurements and estimate characteristics they lack equipment to measure. According to Validere Technologies Inc., the software’s provider, more accurate and comprehensive quality data can help users access the most profitable markets for their product.

“Most producers know they can get more for each barrel if they have reliable information about product quality, such as vapor pressure, water content, sulfur or total acid number, to avoid unnecessary penalties and find the best market,” Le Dain says. “The issue is that getting better quality data traditionally requires a significant investment in instruments that sometimes can be hard to justify because the lack of data makes the return unknown.”

To generate quality data at a lower cost, Validere has developed models that Le Dain says apply physics and statistical and spatial reasoning to infer quality based on meter readings, samples and other information. These models work best when they can draw on readings from several instruments, but Le Dain says they are reliable enough to be useful even for small companies that only take a sample or two a day.

“By implementing these models in cloud-based software, we can give producers, midstream firms and refineries real-time product quality information,” Le Dain reports. “The models predict quality accurately enough that we can tell when a meter needs to be recalibrated and either alert the user or handicap the readings in the software to correct the drift automatically.

“By comparing data from several instruments, we can even infer measurements that are not being taken,” he adds. “For example, our virtual analyzers can track vapor pressure in real time and feed that data into producers’ SCADA systems so they can make more informed operational and marketing decisions.”

For producers to rely on virtual analyzers, they need to offer reliable data, Le Dain notes. “Before many customers adopt us, they compare measurements from our virtual analyzers with ones from in-line meters and labs. The virtual analyzers usually are more accurate than physical ones because quality varies so widely that meters go off calibration more quickly than the manual suggests. Most meters need to be recalibrated more frequently.”

Once customers are comfortable using the software to optimize their sales points, Le Dain says, the return can be significant. “We often see 100% or 200% returns,” he details. “The returns are strong whether the client is a large company with a dedicated marketing group or a small producer that relies on us to analyze its data and send recommendations.”

Validere’s software also can help shrink environmental footprints. “More precise data can allow producers to get into a closer pipeline that has stricter quality specifications, which means fewer carbon miles,” Le Dain illustrates. He mentions that the software can quantify undriven miles to help with ESG reporting.

“In the long run, we think we will be able to reduce emissions even more by helping operators find molecules lost to venting as they balance facilities,” Le Dain says. “Think about a tank or pipeline. If the volumes at the outlet are lower than the ones at the inlet, flashing or a leak may be the culprit. This math-based approach to finding emissions always has been possible, but it should be far more effective with software that can improve measurement accuracy and automatically flag concerns.”

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.