Stress Modeling

‘3-G’ Workflow Pinpoints Shale Sweet Spots

By Ahmed Ouenes

THE WOODLANDS, TX.–Successfully drilling unconventional and tight sand wells requires identifying geologic and geomechanical sweet spots. Geomechanical sweet spots depend largely on two factors:

The interaction of regional stress with natural fractures, and two resulting key geomechanical sweet spot indicators: local horizontal differential stress, and local horizontal maximum stress direction; and

The interaction between hydraulic and natural fractures, which can be accurately modeled and validated with microseismic data and other frac stage performance indicators.

Extensively using geophysical and geologic data in geomechanical simulation (3-G workflow) enables operators to identify and validate low-differential stress zones (which allow the development of frac complexity) and reservoir strain that results from hydraulic stimulation of the naturally fractured reservoir with microseismic data and production logs. Another key output of a field-validated 3-G workflow is identifying areas where local stress rotation occurs, thereby preventing the development of transverse fracs.

Given the large capital expenditures required to develop unconventional oil and gas reservoirs, the industry has made numerous advances in reservoir modeling technology with the goal of improving production forecasts, reducing uncertainty and optimizing net present value. The common thread behind these reservoir modeling improvements has been a constant effort to honor the geology. In naturally fractured reservoirs such as shales, for example, a similar evolution of modeling improvement has been made where randomly distributed discrete natural fracture numerical modeling has been replaced by continuous fracture models that follow recognized geologic drivers controlling fracturing.

Honoring the geology becomes a major challenge when dealing with scarce well data. However, that challenge can be addressed with 3-D seismic data when it is used in geologically driven modeling workflows. Having geophysical data available in a large reservoir volume can reveal the intricacies of complex geology. When combining well and seismic data in algorithms such as stochastic or geostatistical inversion, or building geostatistical or neural network reservoir models constrained by one or more relevant seismic attributes, the resulting high-resolution description of the subsurface can dramatically reduce uncertainties in production forecasts.

Building on two decades of progress integrating geology and geophysics, geomechanical modeling for completion optimization can benefit from past lessons learned, and hopefully, provide the required next generation 3-G output models that will lead to better production forecasting.

Three Major Components

The successful development of unconventional resources requires the recognition of three major components: the geologic heritage, the stress environment, and “free will” variables associated with fracturing and completion designs.

An unconventional well is drilled in a geologic setting that is the result of very complex transformations that include deposition of sediments and organic matter, compaction, maturation, diagenesis, multiple tectonics events, etc. This geologic heritage caused a reservoir that has heterogeneous lateral and vertical distribution of elastic properties such as Young’s modulus and Poisson’s ratio.

These elastic properties, direct indicators of key rock properties such as brittleness for example, play a major role in hydraulic fracturing and could be estimated directly from prestack seismic elastic inversion. The complex geology that induced these heterogeneous elastic properties is estimated in the entire reservoir volume using advanced geophysical analysis and modeling. This allows the interpreter to estimate the dynamic elastic properties that could be calibrated to laboratory measurements and provide the necessary input required for geomechanical modeling. The geologic heritage also includes total organic carbon (TOC), porosity and natural fractures.

In other words, the geologic heritage controls both the available resource, represented by the product of porosity and TOC, as well as the plumbing, represented by the brittleness and the natural fracture density, which will turn the resource into reserves.

Once a well is drilled, it will be impacted by its stress environment. The regional stress will exert pressure on the wellbore and its surrounding area, and the stress anisotropy created by a multitude of geologic factors (including the presence of natural fractures and nearby faults) will cause this stress to vary along the wellbore. Neighboring fractured and producing wells will affect the stress field of nearby wellbores. The success of a completion depends significantly on this perturbed stress field, its horizontal differential stress, and the local maximum horizontal stress direction (which could be different from the overall regional stress direction).

Geophysics can be used to directly estimate some of these stress properties. However, this requires wide-azimuth seismic data, and the workflows needed to process these data are time-consuming. A 3-G workflow provides a faster and more efficient way of using simultaneously geology, geophysics and geomechanics to estimate differential stress and the local maximum horizontal stress direction.

Free will allows a shale well to have any length, any frac size or proppant type, any number of frac stages positioned at any location along the wellbore, and could be completed sequentially, as a zipper frac or any other frac sequence. All of these free will variables could be adjusted and optimized, but final well performance will depend on free will as well as the geologic heritage and stress environment. Finding the best geologic heritage is addressed with the application of shale capacity concepts that extensively use geophysics and geology to pinpoint geologic sweet spots and the best landing zones.

Unfortunately, drilling in a geologic sweet spot is a necessary, but not sufficient, condition for a successful well. The best production from an unconventional well will be achieved by also fracturing into the geomechanical sweet spots, where transverse fracs will be able to grow in length and complexity. This requires applying a 3-G workflow.

Completion Optimization

The horizontal differential stress magnitude and local maximum horizontal stress direction must be derived in order to accurately model any hydraulic fracturing process. The presence of faults and natural fractures, and their interaction with the regional stress, creates a heterogeneous stress field that will have zones with lower differential stress that promote the development of frac complexity during stimulation as well as higher-differential stress zones that inhibit complex frac growth.

Lower-differential stress zones tend to demonstrate greater complexity, while high-differential stress zones tend to exhibit less complexity, as seen in diffuse or linear microseismic responses, respectively. This differential stress heterogeneity can be mapped accurately using a geomechanical simulation in 2-D plane strain theory of the interaction between regional stresses and natural fractures within a specific geomechanical reservoir layer. Geology and geophysics are the keys behind successfully mapping natural fractures to ensure the proper estimation of the horizontal differential stress.

Natural fracture distribution can be derived in multiple ways, ranging from simple seismically driven proxies such as volumetric curvatures and coherency, to more sophisticated approaches using shear-wave anisotropy. The most accurate natural fracture models used so far in geomechanical modeling combine multiple geophysical attributes and geologic models to form continuous fracture models. Unlike reservoir simulation, where high-end continuous fracture models are needed to match well performances, geomechanical modeling allows for simple, yet robust proxies such as coherency and curvature to provide very reasonable natural fracture distributions in certain tectonic regimes.

These simple natural fracture proxies lead to reliable differential stress maps, which when used in the proper geomechanical simulation tools, allow the capturing of the complex interaction of hydraulic fractures with these naturally fractured reservoirs. One simple way to verify that natural fracture distribution is realistic and the resulting differential stress map is correctly estimated is to use microseismicity and/or production logs as validation data. Low-differential stress zones generally have more microseismic events and better frac stage performance as measured by a production log. In addition to providing the differential stress map, which represents a critical geomechanical sweet spot indicator, the natural fracture distribution and its interaction with the regional stresses point to zones where stress rotations may occur.

Since most shale wells are drilled perpendicular to regional stresses to create transverse fracs, any local stress rotation could hinder this objective. Instead of transverse fracs, the stage could develop nonorthogonal or even longitudinal hydraulic fractures with an inability to grow in length or complexity. This extremely important part of the shale’s non-unique “personality” can cause serious frac stages interferences. Not fully understanding a naturally fractured shale’s response to hydraulic fracturing will likely lead to poor frac stage performance.

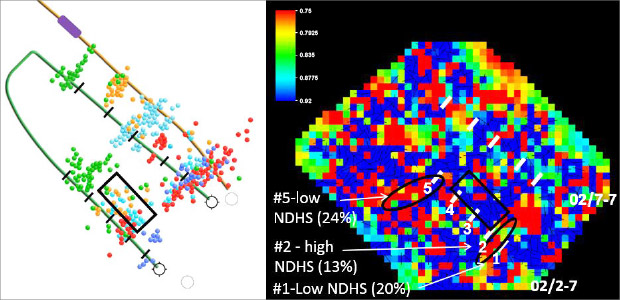

FIGURE 1

Normalized Differential Horizontal Stress and

Maximum Horizontal Stress Direction (Montney Shale)

Montney Shale Example

Figure 1 shows one of the 3-G workflow outputs from the Montney Shale, displaying the normalized differential horizontal stress with the maximum horizontal stress direction. The red zones, such as those highlighted with ellipses around stages 1 and 5 of the No. 02/2-7 well, represent low normalized differential horizontal stress values where production logs show the best frac stage performance of at least 20 percent. The worst frac stage performance at Stage 2 (13 percent of 02/2-7 well production) is mainly surrounded by high normalized differential horizontal stress values, which could explain its poor performance.

Estimating local maximum horizontal stress direction revealed the presence of stress rotations. While the two wells were drilled perpendicular to the regional stress direction of N40E, the maximum horizontal stress direction (shown in black lines in each cell) appears to have rotated by 60 to 90 degrees in the area highlighted by the rectangle. The results of this geomechanical simulation are supported by microseismicity, which shows events highlighted by the rectangle lining up perpendicular to the direction of regional stress. This is most likely an indication of longitudinal frac development around Stage 3.

Geomechanical modeling can benefit tremendously from extensively using geophysics and geology to provide a realistic distribution of natural fractures and other key inputs. When realistic natural fracture distributions are input in appropriate geomechanical simulations, the horizontal differential stress and the local maximum horizontal stress directions–two key indicators of geomechanical sweet spots–can be estimated and validated with microseismic and frac stage performance indicators such as production logs.

It is only after finding and validating these basic initial conditions that putting pressure and fluids in the hydraulic fractures to predict reservoir strain and closure stress to optimize well spacing and recovery rate becomes pertinent. Estimating and modeling proppant distribution and the stimulated propped permeability resulting from hydraulic fracturing must start with properly estimating and validating the initial geomechanical conditions represented by the horizontal differential stress and the local maximum horizontal stress directions.

Editor’s Note: The author acknowledges Yamina Aimene at Oregon State University; Peter O’Conor at SIGMA3; and Radouan Smaoui, Nick Umholtz and Samuel Raymond at FracGeo for their contributions to the preceding article.

Ahmed Ouenes is chief executive officer and founder of FracGeo in The Woodlands, Tx., which is focused on developing 3-G concepts to optimize well spacing and completions, estimate stimulated permeability and proppant distribution in the stimulated reservoir volume, and predict microseismic events. Before founding FracGeo, Ouenes served as global director at SIGMA3. He had previously served as founder and president of Prism Seismic, chief reservoir engineer at RC Squared, executive vice president of an independent oil and gas producer, senior analyst at Sandia National Laboratory, and vice president and co-founder of Correlations Company. He holds a degree in aerospace engineering from Ecole Centrale de Paris and a Ph.D. in petroleum engineering from the New Mexico Institute of Mining and Technology.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.