Procurement Best Practices

Collaborative Supplier Relationships Boost Profits

By Mark Montanari

A natural gas gathering, processing and transportation company increased its weekly rail shipping capacity 50% and significantly improved its earnings before interest, taxes, deductions and amortization by working more closely with its suppliers.

As part of that effort, the midstream firm approached its rail provider to negotiate a quid pro quo arrangement that gave it access to three additional switches. The two companies also implemented daily and weekly reports to help them identify operational issues, streamlined workflows to maximize their human resources, created a process for diverting excess rail cars to remote storage facilities before they reached the yard, and developed methods for analyzing fleet utilization so they could determine when to sublease excess inventory.

In other words, they moved from a transactional relationship to one focused on working together to ensure mutual growth. That partnership-oriented approach could yield huge benefits for companies in a variety of sectors, including exploration, drilling and production.

Most suppliers and service companies realize that. Across industries, 71% say they could do more for customers by developing stronger partnerships. Drawing on experience with the customers with which they already have strong relationships, they estimate the typical improvement at 9%.

To leverage their suppliers’ full capabilities, exploration, drilling and production companies; upstream service providers; and midstream firms must move away from the sourcing-centric approach commonly used for procurement toward a more collaborative approach. This may require a radical change in leadership behaviors for both a company and its suppliers, but it will deliver sustainable value and provide a compelling return on investment.

Three Stages Of Evolution

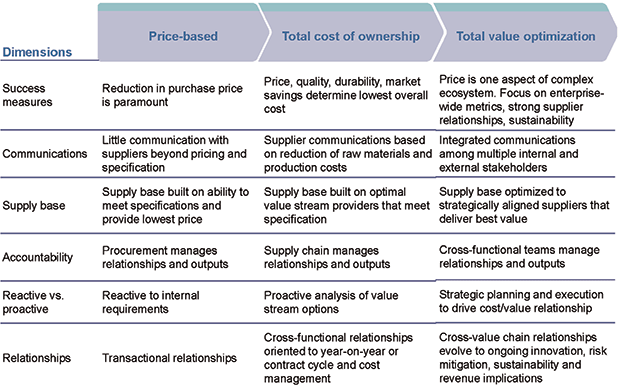

Most companies already have moved beyond the simplest procurement model, in which price almost exclusively drives purchasing decisions. This model is reactive in nature and involves limited communication with suppliers beyond that required for pricing negotiations, so it is easy to implement.

Under the price-based model, a procurement team may use a reverse auction to secure the lowest price possible on valves or pump components. The low price may be beneficial in the short term, but costs associated with more frequent replacements and unplanned downtime can exceed the immediate savings rapidly.

With that in mind, most mature organizations have moved to a procurement model centered on total cost of ownership (TCO). Because this model considers how product quality and durability affect costs, it has a higher chance of helping the organization identify strong suppliers.

Unfortunately, with its single-minded focus on costs, the TCO model often leaves opportunities for improvement on the table. Consider completion chemicals.

While it’s possible to purchase commodity solutions from low-cost providers, it may be beneficial to partner with suppliers who have the staff, expertise and facilities to analyze specific applications and suggest chemical blends more closely aligned with corporate objectives. For example, a producer could increase production by replacing traditional friction reducers, which tend to plug the formation, with more expensive but less damaging alternatives.

Instead of viewing the purchase as an isolated transaction, the producer should consider partnering with the chemical supplier to work toward continuous improvement. By communicating more frequently to gain a deeper understanding of each other’s needs and capabilities, they may be able to streamline their supply chain. For example, if the chemical supplier knows the producer is moving into shallower, cooler formations, it can recommend chemistries that trade heat resistance for a lower cost or simpler transportation and storage.

The idea is to leverage supplier capabilities to create value for the company and the supplier ecosystem. This relationship-oriented model, called total value optimization (TVO), can be applied to a variety of oil field activities. In fact, many of the best producers already work closely with their drilling contractors and pressure pumpers to identify ways to reduce time on location and deliver more productive wells. In urban areas, they may also collaborate to minimize operational impacts such as noise, light and traffic.

As noted in Table 1, applying or expanding the TVO model requires a holistic approach to evaluating suppliers, greater stakeholder participation, long-term relationships, and a commitment to innovation. It also means redefining and sometimes eliminating the functional boundaries between stakeholders. This will not happen without C-level commitment.

Implementing The Model

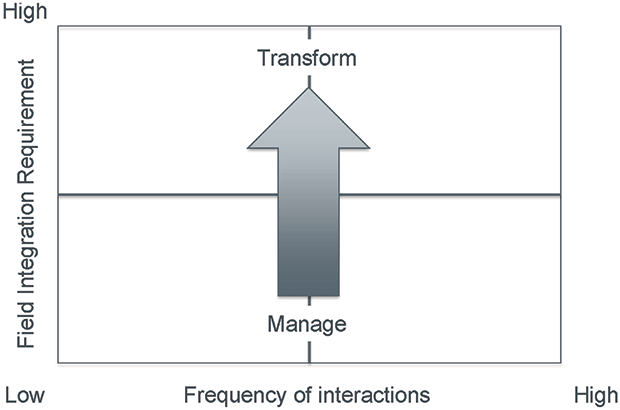

The effort necessary to capture the full value from a supplier relationship varies from activity to activity. In general, suppliers who directly impact field-level operations need the most attention.

Figure 1 shows the relationship between field integration requirements and the amount of change needed to move from managing total cost of ownership to maximizing value. In the lower quadrants, a strategic procurement event organized by a cross-functional team may be enough.

The upper quadrants demand more comprehensive change programs. In the upstream space, the upper quadrants include drilling, proppant logistics, produced water management and production chemicals.

To implement the TVO model, a company and its suppliers need to understand each other’s capabilities and goals so they can take steps that come with enough mutual benefits to be sustainable. This generally means the relationship will involve executives because they have the broad perspective needed to identify those steps and the influence to ensure they are embraced.

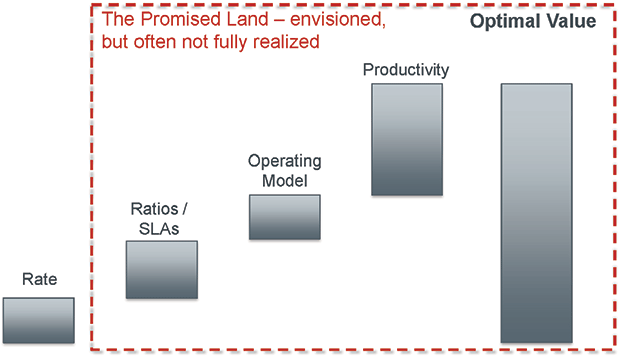

The benefits of fully leveraging supplier capabilities make the time invested worthwhile. Figure 2 shows the vast gulf that exists between the value generated using prevailing procurement models and the value achievable with TVO.

Figure 2 also shows that contracts requiring complex integration will only succeed with input from procurement and operations. While procurement teams can help find reasonable rates and negotiate contracts, operations teams need to be involved from the beginning to ensure the contract’s performance metrics reflect their goals. Once the contract is signed, operations teams need to implement practical and concrete procedures for working with the supplier, or its benefits may never materialize.

Supplier Management Pitfalls

For upper quadrant activities, maintaining supplier relationships often means adopting comprehensive management systems with supporting metrics and dashboards. Like other elements of the relationship, these systems must be implemented carefully to be effective. Dashboards mean little unless they provide visibility into the right metrics and are part of a disciplined approach to a relationship in which people have clear roles, responsibilities and deadlines.

One of the biggest mistakes companies make after signing a contract is poor follow through. Over time, supplier relationships can devolve into entering routine data and renewing contracts.

Alternately, the relationship may be abdicated to local teams that have a narrow perspective on corporate goals and too little influence to adopt value-creating changes.

Another common mistake is lack of key performance indicators for monitoring whether the relationship meets its goals. When KPIs exist, they often focus on safety and adherence to payment terms, with a limited view to performance and productivity. The contract’s goal should be to drive continuous improvement not only in safety, but also in productivity. Over time, that will mean wells get drilled faster, sand arrives on time, and artificial lift systems produce more and last longer.

Even the best contract and supplier management systems will fail if end-users refuse to modify their day-to-day interactions with the supplier. With that in mind, companies should include affected business units in contract design and implementation to ensure they see the contract’s value and are committed to capturing it. Executives and managers also need to spend time selling the changes to their subordinates. Without buy-in, workers may ignore the contract’s mandates in favor of familiar and therefore relatively simple processes.

While implementing a contract, it’s also important to place decisions at the right levels. Ideally, the people responsible for each decision should have easy access to relevant information–or at least supporting processes to get that information–so they can make choices quickly and consistently that reflect the company’s goals and values.

With the right mind-set and the commitment to follow through, producers, service providers and midstream firms can unlock the promise of total value optimization. This advanced procurement model emphasizes forming collaborative relationships with suppliers that involve continuous improvement and financial sustainability for all parties because such partnerships deliver greater safety, efficiency and profit.

Header image courtesy of Hi-Crush.

MARK MONTANARI is vice president of the chemical and oil and gas sectors at Maine Pointe, a global supply chain and operations consultancy. He has a long track record of designing and implementing organizational, process and technology changes, particularly for chemical and oil and gas companies. Montanari is a regular presenter and has published articles frequently in the value chain and risk management realm that focus on implementing new operating models and improving partnerships to drive value and reduce risk.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.