Seal Selection

Extreme Environments Demand Appropriate Sealing Choices

By Steve Jagels

HOUSTON–In the upstream oil and gas industry, the search for hydrocarbons is leading companies to drill deeper and pursue reserves that are increasingly hard to reach. In contrast to the days of abundant oil in easily accessible fields, exploration now commonly involves tapping historically inaccessible sources often found in harsh and demanding terrains and environments.

The demands of such operating conditions have given rise to a new wave of challenges for equipment manufacturers and procurement professionals. Today’s industry is charged with implementing products that deliver required results and performance despite the severe conditions in which they are deployed.

In this context, the potential implications of a seal failure can be staggering. Seal malfunctions in drilling, pumping and pipeline assets can have massive financial repercussions for the operating company, draining revenue through downtime and additional repair costs. Seal failures also constitute a significant personal safety hazard because they increase the risk of explosions and fires. Furthermore, seal failure in offshore drilling can damage local ecosystems, with considerable cost to local tourism and fishing industries. For these reasons it is imperative that companies carefully select all sealing materials according to the application for which they will be used.

High Temperature Steam

In Canada, the decline of conventional oil targets has led many exploration companies to turn to modern technology to access natural resources locked within abundant tar-rich oil sands. The inclusion of oil sands in Canada’s proven reserves was at one time a point of controversy because it was financially prohibitive to extract refinable oil from bitumen mixed with sand. However, promising techniques, such as steam assisted gravity drainage (SAG-D), have allowed oil and gas companies to overcome considerable economic and financial barriers.

However, steam presents a particular difficulty for elastomer seals of all types, as it commonly cracks and embrittles the material, leading to seal failure and leakage.

Drier, high-temperature conditions as hot as 200 degrees C require heat durable materials such as fluoroelastomers (FKMs), which are considered high performance solutions for high-temperature applications. For even higher temperatures, it is necessary to use perfluoroelastomers (FFKMs) that can function in temperatures as intense as 327 degrees C while maintaining a reputation for exceptional performance when working with hydrocarbons and corrosive fluids.

Although high performance FKMs and FFKMs can handle oil and oil-based fuels at very high temperatures, they typically do not exhibit the same resistance to steam. High temperature steam causes these types of elastomer to become brittle and crack, making them unsuitable for such an environment.

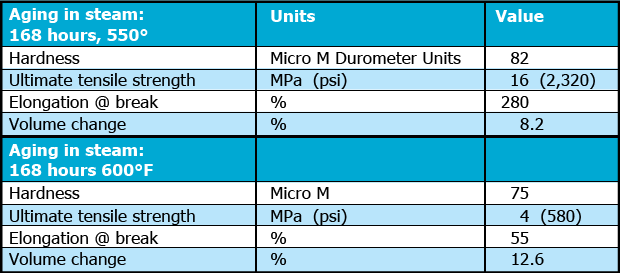

To address this problem, researchers have developed a type of elastomer technology to specifically withstand high temperature steam. The material is an improved type of ethylene propylene diene monomer (EPDM) that optimizes the polymer, cure system and fillers to maximize steam resistance, allowing it to outperform even the highest grade FFKMs. The results in Table 1 show that after 168 hours of steam aging at 315 degrees C, the superior EPDM retains its properties to maintain an effective seal.

For applications involving exposure to high temperature steam such as SAG-D, improved EPDM seals and O-rings offer the best solution for submersible pumps, valves and tools requiring critical seals. Specialty EPDM can improve reliability significantly while considerably reducing system downtime.

In addition to SAG-D, specialty high temperature, steam resistant EPDM may be used in geothermal applications.

Subsea Considerations

While land-based oil operations face increasingly demanding conditions, offshore drilling presents an even tougher challenge. The harshness and remoteness of drilling locations often requires an extremely large investment. In order to access deeper sources, companies have been relying on subsea operations that do not require surface facilities.

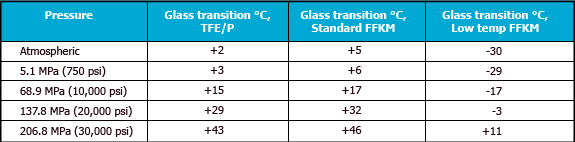

In the offshore oil and gas industry, one of the main difficulties with sealing subsea equipment involves the low temperatures and high pressures exerted on the seals. Seawater temperatures typically range between 0 and 3 degrees C and, when combined with the high pressures common to deep water, it is possible that valve and subsurface equipment seals may fail. This is attributable to the water’s low temperature and the increase in the glass transition of a seal’s elastomer as extreme pressures decrease its free volume, thereby reducing molecular mobility. One of the primary specifications of valve and subsea equipment seals is the elastomeric barrier they provide to maintain a bubble tight seal; the reduced molecular mobility and increased glass transition calls for better low temperature elastomers.

Although direct laboratory measurements of this effect may be impossible, papers published about the topic include a November 2004 analysis titled “Temperature and Pressure Dependence of Free Volume in Fluoroelastomers from PALS and PVT Experiments,” by G. Dlubek, and a 1989 study “Comprehensive Polymer Science,” by G.B. McKenna.

Designing subsea equipment for this kind of activity presents engineers with unique conditions and a major challenge, because the sealing solution must last for the design life of the equipment and function at high pressures and low temperatures.

For onshore operations, particularly in the arctic, sealing valves requires elastomers that can retain flexibility and a seal in extremely low ambient temperatures. It is first important to consider the key benchmarks and tests for sealing materials that are designed for low temperature performance, which are:

- Temperature of retraction, which indicates the temperature at which a stretched elastomer will retract a given percentage;

- Brittleness point, which constitutes the lowest temperature at which an elastomer will not break or fracture when struck; and

- Glass transition or Tg, which is measured by a precise analytical instrument called a differential scanning calorimeter that indicates a material’s specific heat capacity and the transition of an elastomer from a material with a glass-like composition to one with flexible properties.

If an elastomer’s glass transition specification is unable to meet the demands of the environment in which it is placed, it will begin to display glass-like properties and increase seal failure risk. As previously described, high pressure, low temperature sealing applications, such as deepwater production, require seals with very low glass transition capabilities. This is because the pressure the surrounding ocean exerts on the elastomer increases the glass transition temperature.

Table 2 demonstrates how high pressure may change an elastomer’s ability to seal at various temperatures. As a general rule, for every 5 MPa (725 psi) increase in pressure the glass transition or Tg increases by 1°C.

The Right Solution

The different challenges within oil and gas applications require elastomer seals with very different attributes. The single most important aspect in ensuring system integrity is choosing the correct elastomer type for the specific application. The variety of applications across the oil and gas industry requires customized sealing materials that can maintain their performance under the precise demands of a given operating environment.

Depending on the application, the seals may need to withstand a range of chemical species corrosion inhibitors, high temperature steam, or low temperatures in conjunction with high pressures. However, no single type of elastomer is suitable across all possible applications even within the same industry.

As the oil and gas industry moves to progressively more extreme environments, its elastomer seal requirements are improving to meet the challenges. New specialized sealing materials designed for specific oil and gas applications are available and can be optimized according to the equipment and environment.

Steve Jagels is the global market manager for oil and gas at Precision Polymer Engineering, a unit of IDEX Corp. He has worked as a professional in the polymer industry for 18 years in a variety of roles, including both business and technical. Jagels is a frequent speaker at technical conferences and is an alum of Tulane University and the University of Pennsylvania Wharton School.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.