Hydraulic Fracturing

Fluid Systems Energized With Nitrogen, Carbon Dioxide Optimize Frac Effectiveness

By Robin Watts

AUSTIN, TX.–Unconventional reservoirs present unique challenges for energy producers and oil field service companies seeking to extract the maximum economic lifetime potential from their wells.

These reservoirs are defined by their low permeability, low-to-no porosity, and need for stimulation for economic production. No two formations are alike, and often they are characterized by significant variability within the same formation, thus requiring varying stimulation techniques. Unleashing the value of these unconventional reservoirs relies heavily on the methods of horizontal drilling combined with hydraulic fracturing.

The vast majority of the frac fluids used in shale and tight sand plays are water-based systems, predominantly slickwater or gelled water. However, carbon dioxide and nitrogen share a long and successful history in hydraulic fracturing and well stimulation, including energizing water-based fluids. Energized fluids can be defined as fracturing fluids that include at least one compressible, sometimes soluble, gas phase.

Studies indicate that fracturing with solutions energized by CO2 or N2 can economically achieve significantly more hydrocarbon recovery than nonenergized approaches. One such study found that using energized fluids improved well performance by 1.6-2.1 times, compared with nonenergized solutions.

There is a clear benefit to using energized fluids in the form of improved well productivity, but there also is added upfront cost for the CO2 or N2 supply and mobilizing the equipment needed on the well location. The key questions for the oil and gas producer are when and why to consider using energized fluids.

Fracturing Challenges

The ultimate goal of well stimulation is to achieve the maximum productivity over the life of the well (maximum EUR) at the lowest unit cost while maximizing the area under the decline curve. Achieving economically desirable fracture penetration and conductivity is particularly challenging in unconventional reservoirs.

Fracturing with fluids that are not energized can leave liquids trapped in low-permeability, tight, depleted or water-sensitive formations. Fluid remaining in the formation negatively impacts the physical properties of the rock, lowering the conductivity of the reservoir and reducing or impeding the flow of oil and gas.

In many hydrocarbon-bearing formations, water is the wetting phase and the initial water saturation is very low. The invasion (imbibition) of water from the fracturing fluid can be very detrimental to hydrocarbon productivity, since any additional water remains trapped because of capillary retention. The increase in water saturation significantly reduces the formation’s relative permeability to hydrocarbons, sometimes by orders of magnitude. This adverse water blocking (or trapping) phenomenon is observed in many reservoirs.

Fines generation and clay swelling in water-sensitive formations also can reduce productivity. Clays swell as water invades the formation and contacts the rock around the fracture. The resulting increase in formation skin reduces the ability of the hydrocarbons to flow from the reservoir to the fracture.

Additionally, hydrocarbon transport can be impaired inside the fracture. In many shales and clay-rich sands, the conductivity of the proppant pack drops considerably in the presence of water. The rock-to-fluid interactions soften the rock, further promoting proppant embedment as the rock closes on the proppant.

Given these issues, often in unconventional reservoirs fractured with water-based fracturing fluids, the majority of the water pumped down hole during stimulation treatment is never recovered.

Energizing the fracturing fluid with CO2 or N2 reduces the amount of water necessary to pump the frac job, lowers the leak-off of the water phase, and improves flow back, since the invaded water saturation is lower. In other words, energized fracturing fluids improve the total flow-back volume and rate, and when foamed, significantly lower the total and liquid leak-off coefficient to minimize fluid retention.

Properties Of CO2 And N2

Beyond the general benefits of an energized fluid for hydraulic fracturing, CO2 has enhanced properties that make it the ideal gas to provide energy for removing aqueous solutions and lifting liquid hydrocarbons. It offers high solubility in water for excellent recovery of hydraulic frac fluids and high miscibility for enhancing hydrocarbon flow.

With a density similar to water, liquid CO2 can be pumped into a well with pumping pressures similar to water. At reservoir conditions, CO2 almost always is supercritical, with a specific gravity of 1.0 or sometimes higher.

As the CO2 penetrates the fractured zone, it displaces fluid in the reservoir rock and leaves the reservoir as a gas. In addition, it has excellent miscibility in hydrocarbons and compatibility with formation fluids, allowing for enhanced mobility and recovery. Where readily available, CO2 provides superior benefits as the gold standard of hydraulic fracturing fluids.

Like carbon dioxide, N2 can be used in its pure state or mixed with other components, and typically is more readily available in unconventional reservoir plays. It can be injected into the well in pure form or as a gas. It works effectively alone, without proppant, in formations where the rock effectively props itself.

For liquid-free stimulations, N2 can be ideal for fracturing dry, shallow formations (i.e., coalbed methane). Although less soluble than CO2, N2 can ensure presence in the invaded zone with additional measures, such as delaying flow back to allow the gas phase to penetrate.

Because it is an energized treatment, N2 improves reservoir flow, providing trapped hydrocarbons with lift and reducing leak-off while improving frac fluid recovery. When foamed, it reduces the amount of water required and contributes to reduced liquid leak-off. Because it has a lower density than water, N2 requires more horsepower to achieve the desired pumping pressure and is more practical in lower total depth wells than CO2.

Proper proppant placement is crucial in horizontal wells with multistage treatments, but is challenging to achieve using conventional stimulation fluids. The absence of proppant in formation fractures because of poor proppant placement yields insignificant fracture conductivity.

If the fracturing fluid consists of a gel-based solution, improper flushing of the proppant pack can result in blocking or impeding flow because of gel residue. Gelled fracturing fluids must be retrieved from the formation to clean out as much residue as possible from the proppant pack.

Foamed, energized fracturing fluids provide superior proppant transport properties. Adding CO2 or N2 to the fracturing fluid reduces the need for gelled fluid, and therefore, the amount of residual gel left in the proppant pack. And as issues continue to arise around water usage and management in hydraulic fracturing, adding or using CO2 or N2 can reduce or even eliminate water volumes, greatly reducing the challenges associated with acquiring, transporting, storing, recovering and recycling or disposing of water.

Treatment Choices

When faced with water restrictions, prohibitive management issues, depleted zones, water-sensitive reservoirs, low pressure, or strong capillary forces, it is important to have alternatives that can better address site-specific fracturing needs. Oil and gas producers and service providers have many choices for fracturing treatments. They can choose from gels and polymers, slick or acid water, gases such as CO2 or N2 used in a variety of solutions or on their own, or various combinations of all these.

Gels and polymers typically are used when higher viscosity is required and tend to promote wider, shorter fractures in more ductile rock. Lower-viscosity slickwater or acid water promote longer, thinner fractures in more brittle rock. Energized gases can be mixed, foamed, gelled or emulsified to cover the full range of viscosities and various applications.

To select the appropriate fluid, producers must consider a number of operational factors and reservoir characteristics. Critical reservoir data include insight into the permeability, pressure, water sensitivity, rock mechanics or formation stresses and natural fractures, leak-off, and temperature of the formation, as well as any restrictions or requirements of local gas pipelines.

Operational considerations include the size of the location, availability and cost of acquiring fracturing fluid, managing that fluid (transportation, storage, recovery and recycling/disposal), fluid sustainability and availability, and the environmental impact and overall productivity, including time-to-complete and time-to-production to get salable hydrocarbons flowing to the pipeline.

Modeling Success

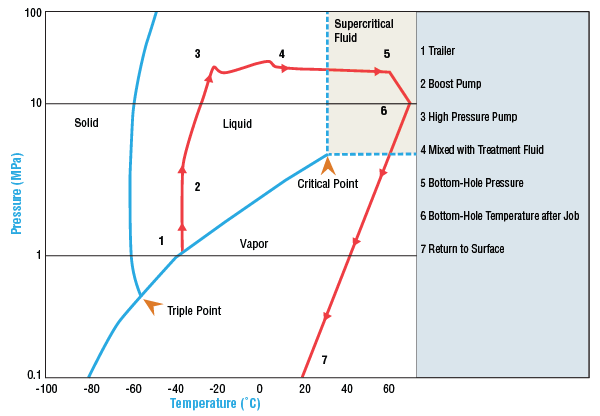

Most commercial simulation software does not account for the phase behavior and compositional changes that occur during an energized fracturing treatment (Figure 1). This makes modeling the effective productivity of an energized fracturing treatment less reliable.

Researchers at the University of Texas at Austin have designed a simulator that does factor in compositional and phase behavior changes for more accurate modeling of a stimulation utilizing energized fluids. Microseismic, logging tools, tiltmeters, mine-back experiments and pressure behaviors are among the monitoring techniques used to determine fracture propagation and to measure the effectiveness of the fracture stimulation.

To strive for the greatest EUR of the well in the most economical way, both well performance and cost must be considered. Costs factored into EUR stimulation economics should include material acquisition (predominantly proppant and water), material management (including recovery, recycling and removal/disposal), horsepower, labor, and refracturing.

Much of the focus is on a well’s initial performance. Encouraged by time-to-production using familiar techniques, producers may neglect to consider alternatives that could minimize the slope of the decline curve.

Long-term well performance and economics can be improved by fracturing with energized solutions. Adding CO2 or N2 to a fracturing treatment has been shown to optimize overall productivity and increase EUR, even though the initial acquisition cost of the gases may be higher than nonenergized slickwater or acid water. The increased productivity of the well effectively reduces unit production costs.

Advantages Of Energized Solutions

The flexibility of energized solutions allows hydraulic fracturing fluids to be mixed according to the technological needs of unconventional reservoirs. They provide more rapid and complete fluid recovery, help to clean without swabbing, and reduce formation damage by minimizing the amount of aqueous fluids introduced into the formation.

In addition, many times energized solutions have superior proppant transport properties without creating ultrahigh molecular weight polymer structures (cross-linking), and in the case of underpressured or depleted zones, provide enhanced energy for hydrocarbon recovery. Flexibility in solution viscosity allows for a more uniform deposition of proppants, improving the conductivity of the propped area to improve the flow of hydrocarbons.

In unconventional reservoirs, energized solutions provide the necessary energy to move hydrocarbons in low-pressure zones or areas with strong capillary forces, because not as much water invades the formation. The solubility and miscibility properties of CO2 provide greater opportunity to energize the flow of higher viscosity hydrocarbons.

Avoiding reservoir damage during stimulation that could inhibit or restrict hydrocarbon flow is critical. Proppant, in effect, can cause damage. Too little or too much proppant, improperly placed or poor-quality proppants, and proppant embedment in reservoir rock all can result in damage or blockage that reduces the flow of oil and gas.

Fractures too far apart, too close together, not appropriately propped, or that tap into nonproductive areas also can result in damage. Residue left from polymers and gels used in fracturing can impede flow through the proppant pack, while overflushing to remove the residue can create fines, whose migration blocks flow. Reservoir and treatment fluid leak-off in aqueous or liquid form can block flow also.

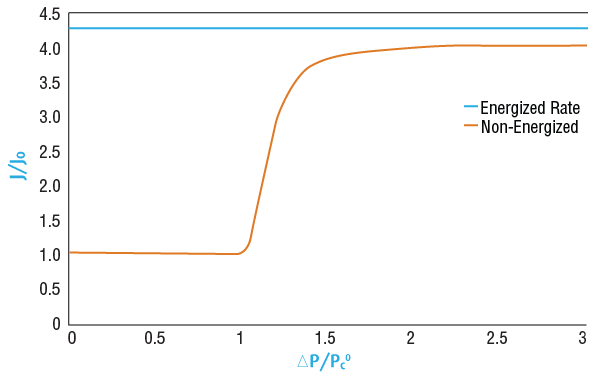

FIGURE 2

Comparison of Predictive Productivity

(unitless measure of J/J0)

of Energized Solutions versus

Nonenergized Water Frac Stimulations

Liquid leak-off increases water saturation, thereby decreasing the formation’s relative permeability to gas. This may play a significant role in damaging gas reservoirs. Energized solutions, however, use less water than conventional fracturing treatments and provide energy for recovering induced fluids while decreasing the fluid leak-off potential to minimize reservoir damage.

Less water means less potential for clay swelling, fines migration, liberating hydrogen sulfide, forming emulsion, and fluid retention. Less damage enhances flow for effective flow back, reducing the time it takes to move to production, while increasing overall production.

Energized solutions are ideal for reservoirs with low permeability, water sensitivity, underpressured or depleted zones, or poor flow back caused by low pressure or strong capillary forces. They also are used for refracturing wells where production has declined.

Because they can be foamed or emulsified to cover a range of viscosities to provide superior proppant-transport properties with slow settling rates, they are good for shales that require fracture length or reservoirs rich in liquids that benefit from fracture width. When foamed, energized solutions significantly reduce fluid leak-off into the formation as well as reduce gel volume requirements, thereby improving fracture conductivity.

Proven Effective

Figure 2 compares the predictive productivity (a unitless measure of J/J0) of energized solutions versus nonenergized water fracture stimulations, using the simulation technology developed at UT Austin. It provides the theoretical framework supporting the improved productivity results from utilizing energized solutions for fracturing.

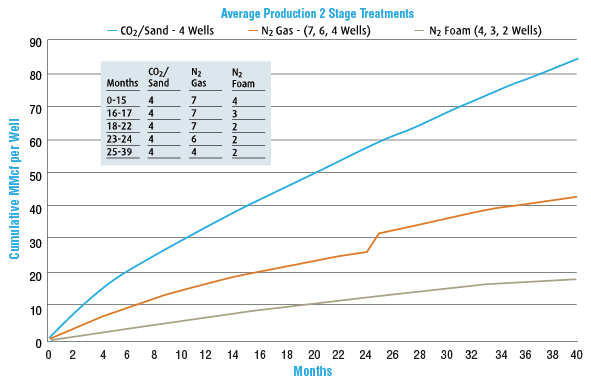

Field studies evaluating energized solutions provide further validation and demonstrate that economic EURs can be optimized using this alternative treatment. Energized solutions have been proven effective from South Texas to the Marcellus Shale. Figure 3 shows cumulative gas production data using energized fracturing fluids in the Devonian Shale in Pike County, Ky.

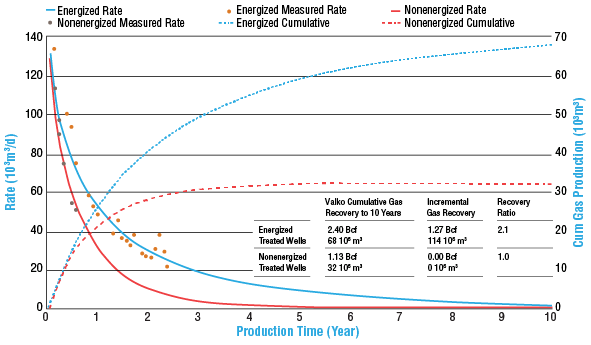

FIGURE 4

Averaged 10-Year Decline Analysis for

Energized versus Nonenergized Frac Fluids

(Montney Shale)

Figure 4 shows how energized fluids dramatically improved well performance, compared with nonenergized solutions, in the Montney Shale in Canada. Energized solutions significantly increased well productivity more cost effectively, presenting opportunities to reduce fracturing resources such as water and proppant volumes, and to reduce injection rates and injection pressures.

They are ideally suited for use in tight, depleted or water-sensitive formations, or to enhance the mobility of more viscous hydrocarbons around and through the wellbore, especially in underpressured reservoirs.

ROBIN WATTS is the oil and gas technology manager for Linde’s Energy Solutions group in North America. Linde is a global industrial gas and engineering firm with North American headquarters in Murray Hill, N.J. Watts has 20 years of experience in developing and commercializing new technologies. The depth of her technical career has focused in the area of material science, while her business career focus has been on successfully applying technology solutions in dynamic markets. As Linde’s oil and gas technology manager, Watts is concentrated on applying energized solutions for hydraulic fracturing. She holds a holds a B.S. in chemical engineering and an M.B.A. from the University of Texas at Austin.

For other great articles about exploration, drilling, completions and production, subscribe to The American Oil & Gas Reporter and bookmark www.aogr.com.